- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

2 月 . 15, 2025 22:53

Back to list

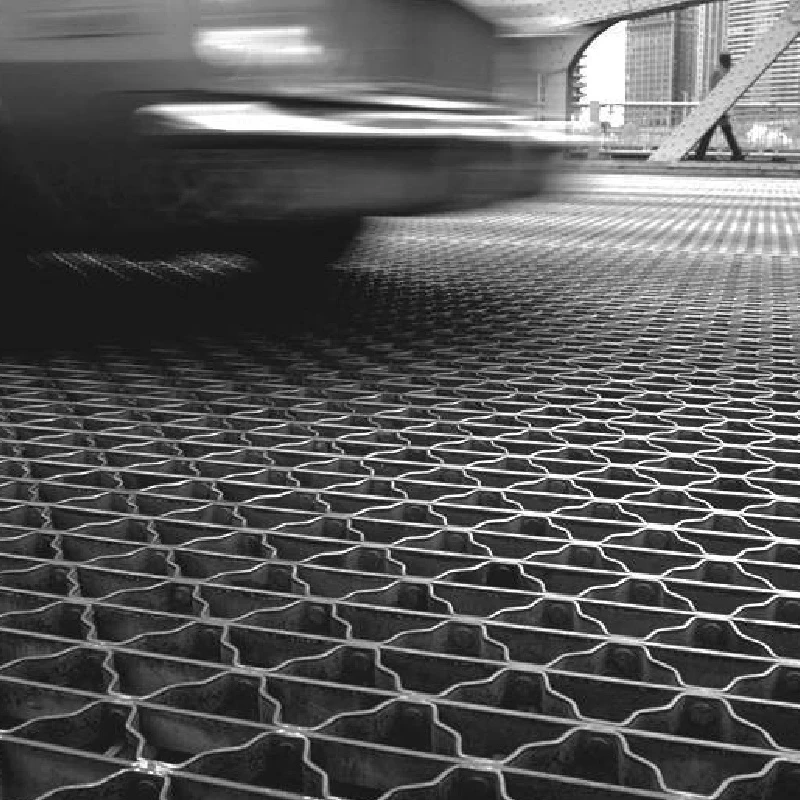

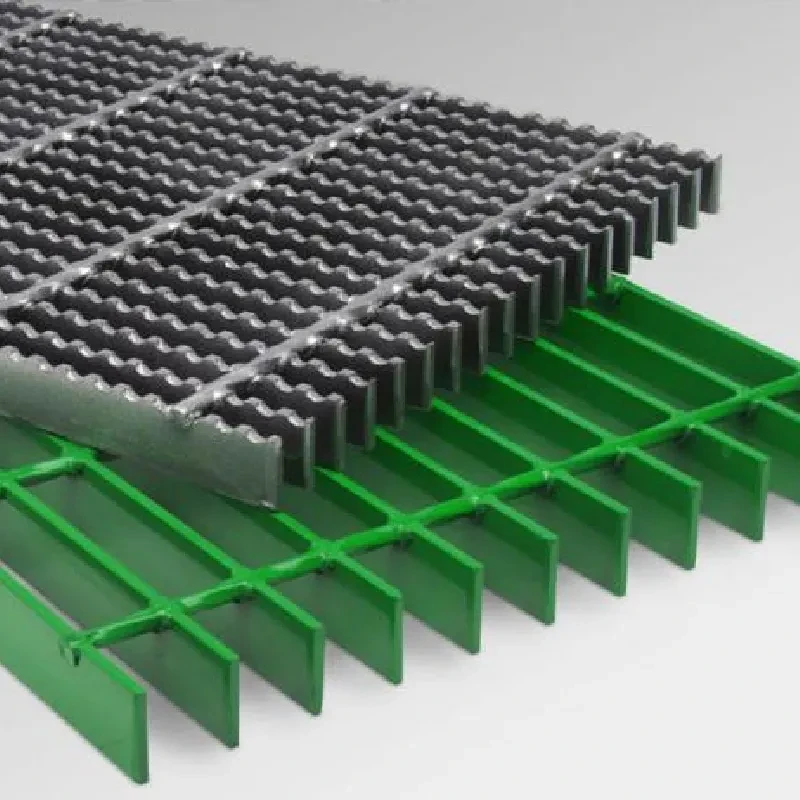

heavy-duty welded bar grating

Smooth bar grating stands as a pivotal component in various industrial applications, offering a seamless blend of functionality, durability, and aesthetic appeal. Engineered meticulously, this versatile product serves myriad sectors with its unique attributes that range from robust load-bearing capacity to remarkable slip resistance, making it indispensable in creating a safe, efficient working environment.

From a safety perspective, smooth bar grating excels in environments requiring enhanced protection against slips and falls. The smooth surface is particularly engineered to offer significant traction even when wet or oily. This characteristic is essential in industries like food processing plants, wastewater treatment facilities, and outdoor public areas, where safety is paramount. Moreover, the versatility of smooth bar grating extends to its adaptability in custom applications. Manufacturers offer a variety of dimensions, surface treatments, and additional features such as serrated edges or nosing options, designed to meet specific customer requirements. This customization ensures that each grating solution is not just fit-for-purpose but optimized for maximum performance within its designated context. Trust in smooth bar grating solutions is bolstered by compliance with industry standards and certifications. Adherence to these benchmarks ensures quality assurance and reliability, instilling confidence among designers, contractors, and facility managers. Partnering with reputable suppliers provides an added layer of trust, as these companies often offer significant technical support and guidance, from the planning stages through to post-installation. In conclusion, smooth bar grating is not merely a component; it’s a sophisticated solution that embodies innovation, safety, and durability. Its application across diverse sectors underscores its relevance and indispensability. For project managers and engineers facing the challenge of selecting the appropriate flooring or structural component, smooth bar grating offers an unparalleled combination of strength, safety, and aesthetic value, positioning itself as a foremost choice in their toolkit. This comprehensive understanding of smooth bar grating affirms its stature as a standout product that is essential for industrial excellence.

From a safety perspective, smooth bar grating excels in environments requiring enhanced protection against slips and falls. The smooth surface is particularly engineered to offer significant traction even when wet or oily. This characteristic is essential in industries like food processing plants, wastewater treatment facilities, and outdoor public areas, where safety is paramount. Moreover, the versatility of smooth bar grating extends to its adaptability in custom applications. Manufacturers offer a variety of dimensions, surface treatments, and additional features such as serrated edges or nosing options, designed to meet specific customer requirements. This customization ensures that each grating solution is not just fit-for-purpose but optimized for maximum performance within its designated context. Trust in smooth bar grating solutions is bolstered by compliance with industry standards and certifications. Adherence to these benchmarks ensures quality assurance and reliability, instilling confidence among designers, contractors, and facility managers. Partnering with reputable suppliers provides an added layer of trust, as these companies often offer significant technical support and guidance, from the planning stages through to post-installation. In conclusion, smooth bar grating is not merely a component; it’s a sophisticated solution that embodies innovation, safety, and durability. Its application across diverse sectors underscores its relevance and indispensability. For project managers and engineers facing the challenge of selecting the appropriate flooring or structural component, smooth bar grating offers an unparalleled combination of strength, safety, and aesthetic value, positioning itself as a foremost choice in their toolkit. This comprehensive understanding of smooth bar grating affirms its stature as a standout product that is essential for industrial excellence.

Share

Next:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024