- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

2 月 . 13, 2025 08:18

Back to list

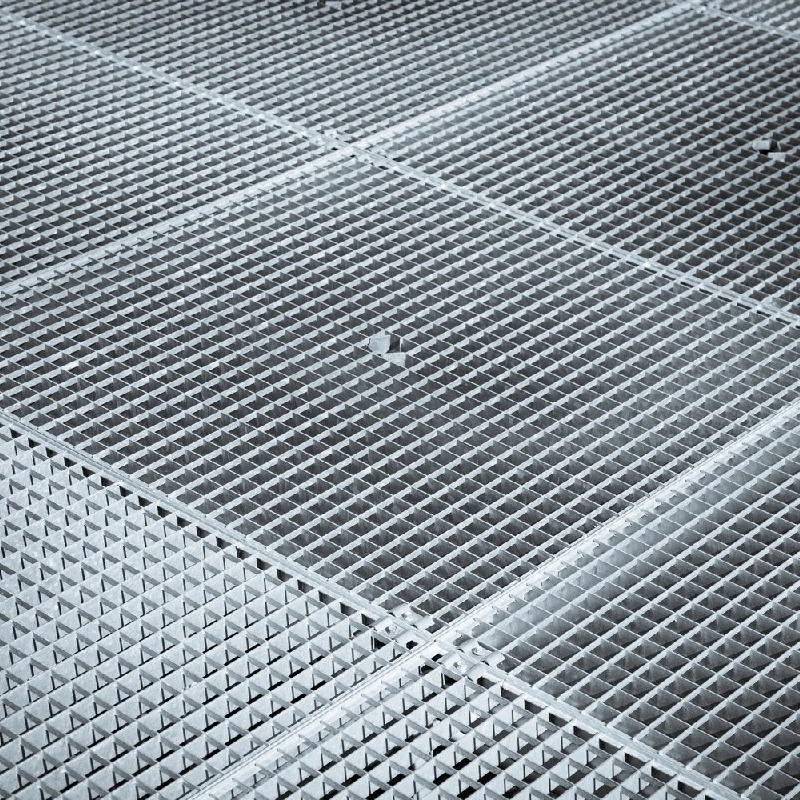

Shale Shaker Screen

The oil and gas industry constantly pushes the boundaries of technological innovation, and among its many tools, the shale shaker screen holds paramount importance. Selecting the right shale shaker screen supplier can greatly influence the operational efficiency and productivity of drilling operations. For companies aiming to optimize their extraction processes, a comprehensive understanding of shale shaker screens and key considerations when choosing suppliers is crucial.

Trustworthiness plays a crucial role in the supplier selection process. When a supplier maintains transparent communication lines and exhibits honesty in transactions, it fosters a strong partnership. Trust can also be reinforced through robust customer support systems that are responsive and solution-oriented. Furthermore, reviews and feedback from previous clients provide third-party validation of the supplier’s claims. A trusted supplier will offer warranties and clear terms in dealings, ensuring accountability for the products provided. Among the top considerations should also be the technological capabilities and the range of products offered by the supplier. Leading suppliers will provide screens made from varying materials and configurations to suit different drilling conditions and environmental regulations. Advanced features like screen mesh layers, weave type, and compatibility with various shale shakers can differentiate high-performing screens from the average. This versatility in product offering ensures that the supplier can meet diverse operational requirements, which is a significant advantage for companies working in varied geographical and geological contexts. It's also advantageous for operators to inquire about the supplier's logistics and delivery capabilities. Efficient supply chain management ensures timely delivery and mitigates risks of operational downtimes. A supplier with multiple distribution centers or strategic alliances globally indicates readiness and capacity to deliver promptly, regardless of location. In conclusion, choosing the right shale shaker screen supplier involves a detailed analysis of experience, expertise, authoritativeness, and trustworthiness. By prioritizing these elements, oil and gas operators can secure products that not only meet technical demands but also contribute to overall operational success. The ideal supplier acts as a partner, offering expertise, quality, and service that align with the operator's strategic goals. As the industry evolves, and drilling conditions become increasingly complex, the role of a reliable shale shaker screen supplier becomes ever more critical — ensuring efficiency and effectiveness in every project undertaken.

Trustworthiness plays a crucial role in the supplier selection process. When a supplier maintains transparent communication lines and exhibits honesty in transactions, it fosters a strong partnership. Trust can also be reinforced through robust customer support systems that are responsive and solution-oriented. Furthermore, reviews and feedback from previous clients provide third-party validation of the supplier’s claims. A trusted supplier will offer warranties and clear terms in dealings, ensuring accountability for the products provided. Among the top considerations should also be the technological capabilities and the range of products offered by the supplier. Leading suppliers will provide screens made from varying materials and configurations to suit different drilling conditions and environmental regulations. Advanced features like screen mesh layers, weave type, and compatibility with various shale shakers can differentiate high-performing screens from the average. This versatility in product offering ensures that the supplier can meet diverse operational requirements, which is a significant advantage for companies working in varied geographical and geological contexts. It's also advantageous for operators to inquire about the supplier's logistics and delivery capabilities. Efficient supply chain management ensures timely delivery and mitigates risks of operational downtimes. A supplier with multiple distribution centers or strategic alliances globally indicates readiness and capacity to deliver promptly, regardless of location. In conclusion, choosing the right shale shaker screen supplier involves a detailed analysis of experience, expertise, authoritativeness, and trustworthiness. By prioritizing these elements, oil and gas operators can secure products that not only meet technical demands but also contribute to overall operational success. The ideal supplier acts as a partner, offering expertise, quality, and service that align with the operator's strategic goals. As the industry evolves, and drilling conditions become increasingly complex, the role of a reliable shale shaker screen supplier becomes ever more critical — ensuring efficiency and effectiveness in every project undertaken.

Share

Next:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

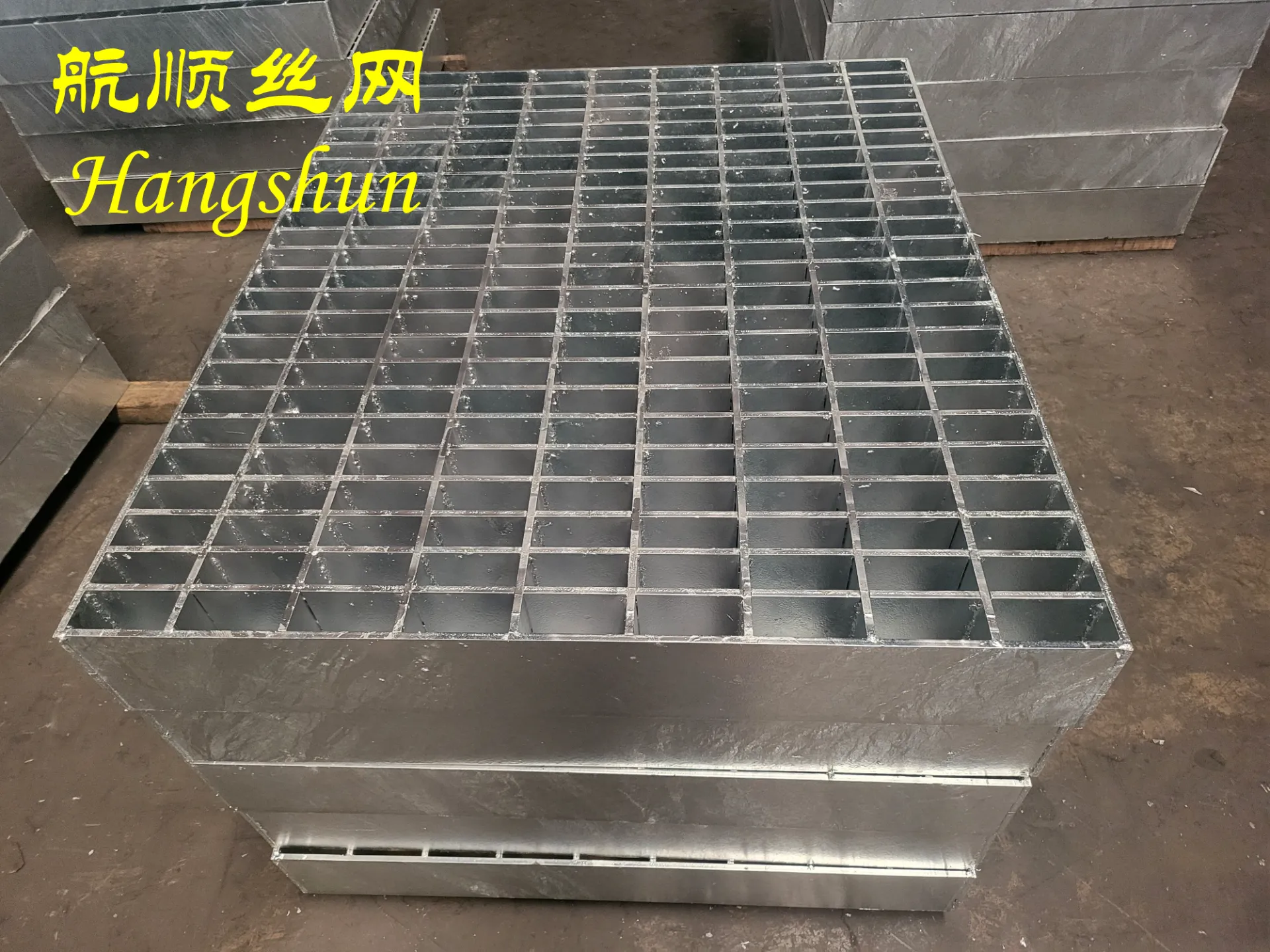

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024