- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

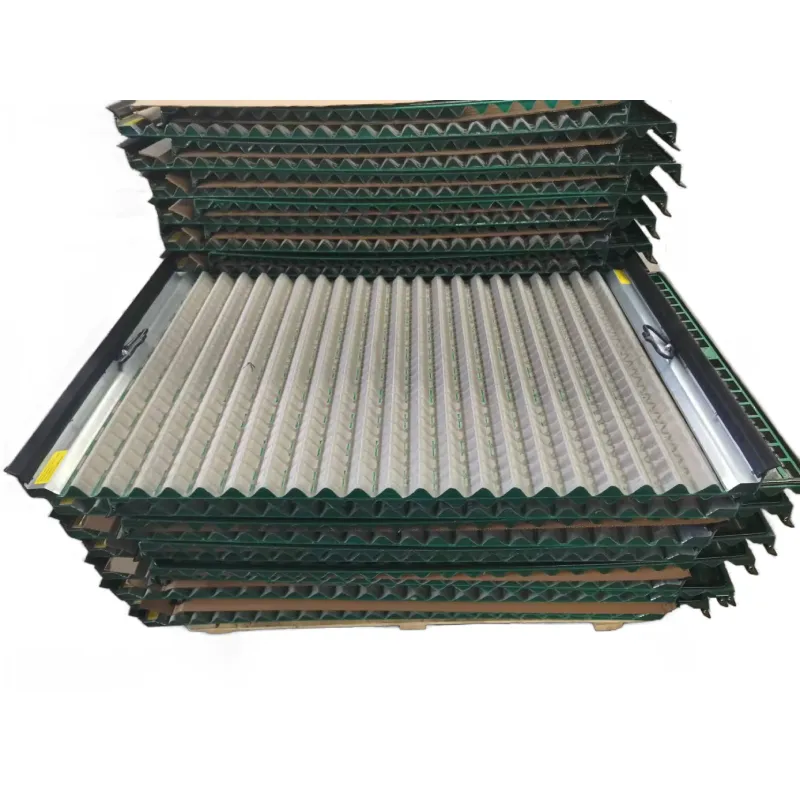

shale shaker screens for sale

Shale Shaker Screens for Sale A Comprehensive Guide to Selection and Purchase

In the realm of oil and gas drilling, shale shaker screens play a crucial role in the separation of drilling fluids and the removal of solids. As the industry evolves, the demand for high-quality shaker screens continues to rise. This article explores the various types of shale shaker screens available on the market, their specifications, and crucial tips for selecting the right product for your needs.

What Are Shale Shaker Screens?

Shale shaker screens are integral components of shale shakers, which are pieces of equipment used to separate drill cuttings from the drilling fluid (also known as mud). The shaker operates by passing the drilling fluid over a set of screens, allowing solids to be removed while recyclable fluid is directed back into the drilling system. The effectiveness of this process is heavily dependent on the quality and characteristics of the shaker screens.

Types of Shale Shaker Screens

There are various types of shaker screens available, with the most common ones being

1. Wire Mesh Screens These are traditional screens made from woven wire mesh. They are durable and can be customized to different mesh sizes, making them versatile for various drilling applications.

2. Composite Screens Made from a combination of materials, composite screens are designed to offer superior strength and longer life. They are lightweight and resistant to blinding, ensuring consistent performance.

3. Polyurethane Screens Known for their flexibility and durability, polyurethane screens are ideal for challenging drilling conditions. They can withstand abrasive materials and are less likely to deform compared to metal screens.

Key Considerations When Purchasing Shale Shaker Screens

When looking to purchase shaker screens, several factors should guide your decision

1. Mesh Size The mesh size determines the size of the particles that can be filtered out. Choosing the right mesh size is crucial; a finer mesh captures smaller solids but may lead to slower fluid flow. Conversely, a coarser mesh allows for higher flow rates but may not filter out all particles.

shale shaker screens for sale

2. Material and Construction The material—a critical consideration—affects the screen’s durability and efficiency. Ensure that the screens are built from high-quality materials suited for the specific drilling environment, whether it’s offshore, onshore, or in extreme conditions.

3. Compatibility Verify that the shaker screens you’re considering are compatible with your existing shaker model. Different models have varying designs and fittings, so it's essential to ensure a proper fit for optimal performance.

4. Durability Look for screens that offer long service life to minimize replacement frequency and costs. Consider the conditions they will be exposed to and opt for screens designed to handle those challenges.

5. Manufacturer Reputation Purchase from reputable manufacturers known for their quality products. Reading reviews and seeking recommendations can provide insight into the reliability and performance of their screens.

Where to Buy Shale Shaker Screens

Shale shaker screens can be purchased from a variety of sources, including

- Manufacturer Direct Sales Many manufacturers sell directly to consumers, which can ensure you get the highest quality screens with direct support.

- Distributors Look for industrial and drilling supply distributors that carry a range of shaker screens and can provide expert advice.

- Online Platforms Various e-commerce websites list shaker screens for sale, enabling you to compare prices and specifications easily.

- Trade Shows Industry exhibitions and trade shows often feature manufacturers showcasing their latest technologies, providing an opportunity to see products first-hand.

Conclusion

Acquiring the right shale shaker screens is essential for efficient drilling operations. By considering factors such as mesh size, material, compatibility, and manufacturer reputation, you can make an informed decision that enhances the performance of your drilling operations. Whether you choose to buy directly from a manufacturer, a distributor, or an online platform, ensure that you are investing in high-quality screens that will effectively support your drilling needs. With the right shaker screens, you can optimize your operations and enhance the overall effectiveness of your drilling projects.

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024