- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

High-Quality Shale Shaker Screens Available for Purchase

Shale Shaker Screens for Sale A Comprehensive Guide

In the oil and gas industry, the efficiency of drilling operations is paramount, and one of the key components that contribute to this efficiency is the shale shaker. A shale shaker is used during the drilling process to separate drilling fluid and cuttings generated by the drilling bit. The effectiveness of a shale shaker greatly depends on the quality and type of screens used. With the growing demand for high-performance shale shaker screens, many manufacturers and suppliers are offering a variety of screens for sale. In this article, we will discuss the importance of shale shaker screens, the types available, and what to consider when purchasing them.

The Importance of Shale Shaker Screens

Shale shaker screens play a crucial role in the drilling fluid management process. They are designed to allow the drilling fluid, often a mixture of water and additives, to flow through while trapping the solid particles or cuttings generated during drilling. This process is essential not only for maintaining the quality of the drilling fluid but also for preventing damage to the wellbore and drilling equipment. The efficiency of the shale shaker, and consequently the overall drilling operation, is directly linked to the performance of the screens.

Effective screens minimize the amount of solids circulating in the drilling fluid, which can lead to faster drilling rates and improved wellbore stability. Additionally, high-quality screens can reduce the wear and tear on drilling equipment, leading to lower maintenance costs and downtime.

Types of Shale Shaker Screens

Shale shaker screens come in various types and materials, each designed for specific applications and drilling conditions

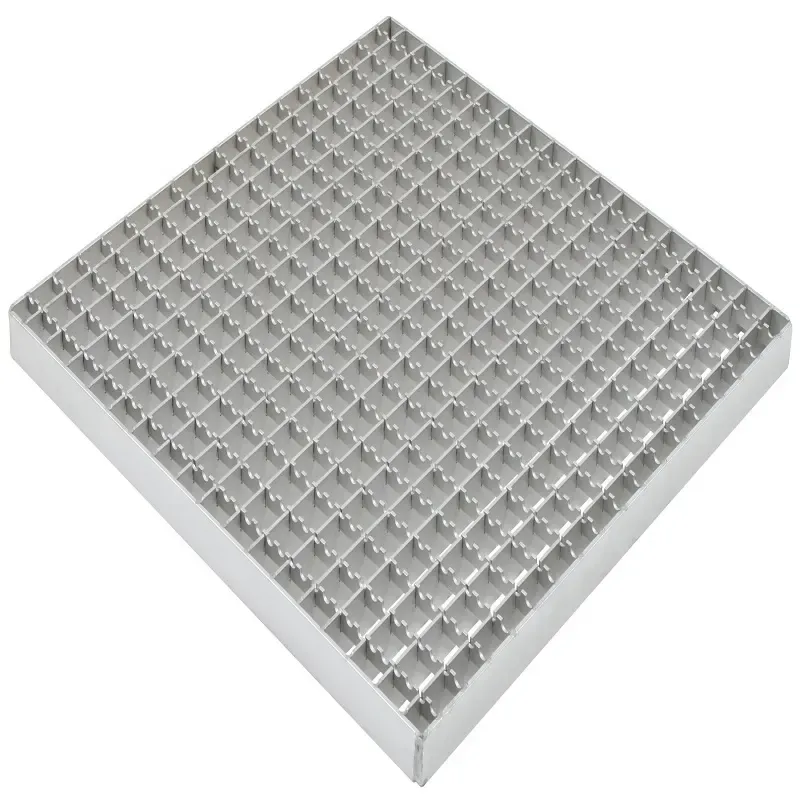

1. Wire Mesh Screens These are the most common type of shale shaker screens, made of durable wire mesh. They are available in different mesh sizes to cater to different drilling applications. Wire mesh screens are known for their effectiveness in separating larger particles from the drilling fluid.

2. Composite Screens These screens are made from a combination of materials, typically featuring a metal frame with a synthetic mesh surface. Composite screens offer enhanced durability and flexibility, making them suitable for a wide range of drilling conditions.

3. Polyester Screens Made entirely from synthetic materials, polyester screens are lightweight and resistant to corrosion. They tend to perform well in specific drilling applications, particularly in offshore drilling operations where exposure to harsh conditions is common.

4. Rubber Screens These screens are designed for severe environments and offer excellent wear resistance. They are often used in applications where abrasive materials are prevalent.

shale shaker screens for sale

5. API Screens The American Petroleum Institute (API) sets standards for shaker screens based on their aperture size and the distribution of opening sizes. API screens ensure a reliable performance and enable compatibility with most shale shakers on the market.

Factors to Consider When Purchasing

When looking to purchase shale shaker screens, consider the following factors

- Compatibility Ensure that the screens are compatible with your existing shale shaker model. Different shakers might require specific sizes and types of screens.

- Mesh Size Choose the appropriate mesh size based on your drilling conditions. A finer mesh is better for smaller cuttings, while a coarser mesh can handle larger debris.

- Material Durability Look for screens made from durable materials that can withstand the specific conditions of your drilling operation, including abrasiveness and chemical exposure.

- Cost Efficiency Assess the cost of screens relative to their performance and lifespan. Investing in higher-quality screens may result in lower overall costs due to decreased downtime and maintenance.

- Supplier Reputation Research suppliers that offer shale shaker screens. Choose companies with a good reputation for quality and service to ensure you receive reliable products and support.

Conclusion

In conclusion, shale shaker screens are critical components in the drilling process, significantly affecting efficiency and cost. By understanding the types of screens available and considering important purchasing factors, operators can make informed decisions that enhance their drilling operations. With a range of options for sale, it's essential to choose wisely to ensure optimal performance on the rig.

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024