- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

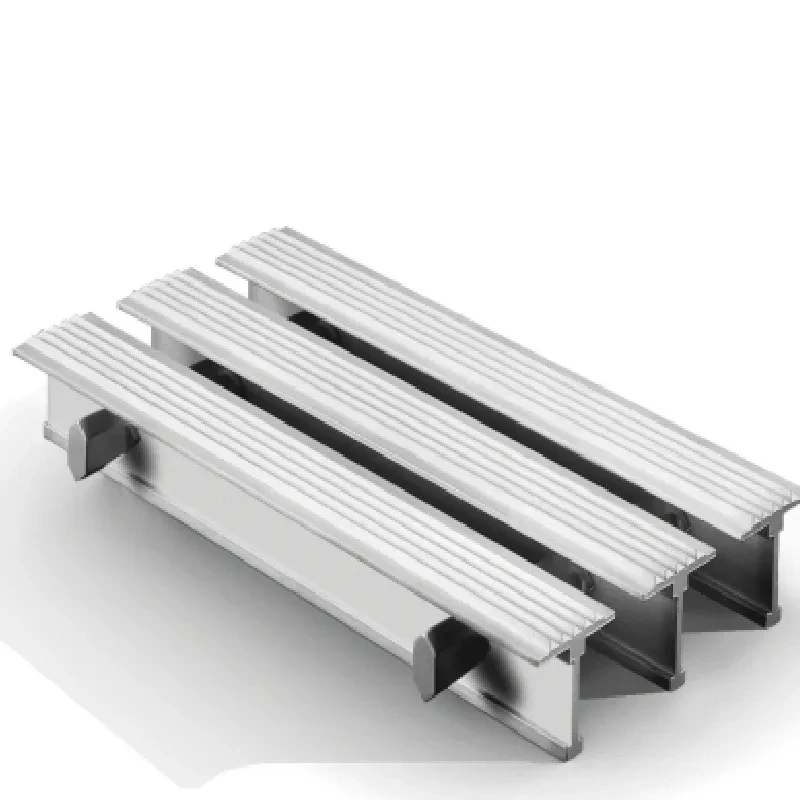

High-Quality Shale Shaker Screens Available for Purchase Online

Exploring Shale Shaker Screens for Sale A Key Component in Drilling Operations

In the dynamic world of drilling, the efficiency and effectiveness of operations hinge significantly on the equipment used. One of the unsung heroes of drilling technology is the shale shaker, specifically its screens. These screens play a vital role in separating solids from liquids, ensuring that drilling mud is cleaned for reuse. As such, understanding shale shaker screens for sale is crucial for anyone involved in drilling, be it in the oil and gas industry or mineral extraction.

What Are Shale Shaker Screens?

Shale shaker screens are mesh-like filters that are mounted on shale shakers, a crucial piece of equipment in drilling rigs. When drilling begins, a mixture of water-based or oil-based mud is pumped down the drill shaft to facilitate the boring process. This drilling fluid, however, collects rock cuttings and other particulates that need to be removed before the fluid can be recirculated. That’s where shale shaker screens come in. They allow the fluid to pass through while blocking larger solids, thereby maintaining the integrity of the drilling process.

Types of Shale Shaker Screens

Shale shaker screens come in various types and sizes, tailored to specific drilling operations. The most common types include

1. Wire Mesh Screens These screens are made from stainless steel and offer durability and reliability. They come in different mesh sizes to cater to the specific requirements of various drilling tasks.

2. Composite Screens Featuring a combination of metal and polymer materials, composite screens provide flexibility and enhanced performance in terms of wear resistance and life span.

3. Synthetic Screens Made entirely from synthetic materials, these screens are lightweight, and easy to handle, and can optimize drilling fluid recovery due to their unique design.

The choice of screen largely depends on factors such as the type of drilling fluid, the size of the solids being removed, and the specific requirements of the drilling operation.

Importance of Choosing the Right Screen

Selecting the right shale shaker screen is critical for the efficiency of drilling operations. An appropriate screen can

shale shaker screens for sale

- Enhance Mud Recovery By effectively separating solids from the drilling fluid, the right screen helps maximize the recovery of valuable drilling mud, which can be reused.

- Minimize Rig Time Efficient screens reduce the time spent on maintenance and replacement, thus allowing drilling operations to proceed without unnecessary delays.

- Improve Drilling Performance Properly functioning screens lead to better overall drilling performance by ensuring that the fluid maintains optimum properties and does not become contaminated by too many solids.

Where to Find Shale Shaker Screens for Sale

The market for shale shaker screens is robust, with numerous suppliers offering various options. Here are some tips on where to look for shale shaker screens

1. Industry Suppliers Many specialized companies sell drilling equipment and accessories. Researching reputable suppliers online can yield numerous options tailored to different needs.

2. Trade Shows and Expos Attending industry-specific trade shows provides opportunities to connect with manufacturers and suppliers directly. This allows for hands-on evaluation of different screen types.

3. Online Marketplaces Websites like eBay, Alibaba, and specialized industrial marketplaces often feature new and used shale shaker screens at competitive prices.

4. Manufacturer Direct Sales Buying directly from manufacturers can sometimes yield better prices and more reliable products, especially if you’re purchasing in bulk.

Conclusion

Shale shaker screens are integral to efficient drilling operations, facilitating the separation of solids from liquids and ensuring that valuable drilling fluids are effectively reused. With various types of screens available on the market, choosing the right one can drastically impact operational efficiency and costs. By understanding the different options and where to find them for sale, drilling professionals can make informed decisions that enhance productivity and performance in their operations. As the demand for efficient resource extraction continues to grow, investing in quality shale shaker screens is more important than ever.

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024