- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Affordable Options for Shale Shaker Screens Pricing and Selection Guide

Understanding the Cost of Shale Shaker Screens

Shale shaker screens are essential components in the oil and gas industry, particularly in drilling operations. These screens are designed to separate drilling fluids and cuttings from the drilling process, ensuring that only the desired materials are transported back to the surface. As a result, the price of shale shaker screens is a significant consideration for drilling companies. This article explores the factors that influence the prices of these screens and provides insight into what buyers can expect when budgeting for their drilling operations.

Factors Influencing Shale Shaker Screen Prices

1. Material Composition The type of material used in the construction of shale shaker screens greatly affects their price. Common materials include stainless steel, polyester, and other composite materials. Screens made from high-quality stainless steel or advanced composite materials tend to be more durable and effective, but they also come at a higher cost. Buyers should weigh the benefits of durability and performance against the initial investment to determine the best option for their needs.

2. Screen Design and Technology Advances in screen technology, such as the incorporation of multi-layered designs and enhanced mesh configurations, can drive up pricing. Modern shale shaker screens are engineered for improved performance, including increased throughput, better separation efficiency, and longer operational life. These innovations result in screens that may be more expensive but can lead to significant cost savings in the long run due to reduced maintenance and replacement needs.

3. Market Demand and Availability Like any other commodity, the price of shale shaker screens is subject to market forces. Fluctuations in oil and gas prices can affect drilling activities, thereby influencing the demand for shale shaker screens. In periods of high demand, prices may increase due to scarcity. Conversely, during downturns in the industry, prices may drop as manufacturers look to maintain sales volumes.

4. Size and Customization Shale shaker screens come in various sizes and may require customization to fit specific drilling equipment. Standard size screens may be less expensive compared to custom-made ones. Buyers should consider whether the need for custom sizes justifies the extra expense and whether pre-fabricated options could meet their operational needs at a lower cost.

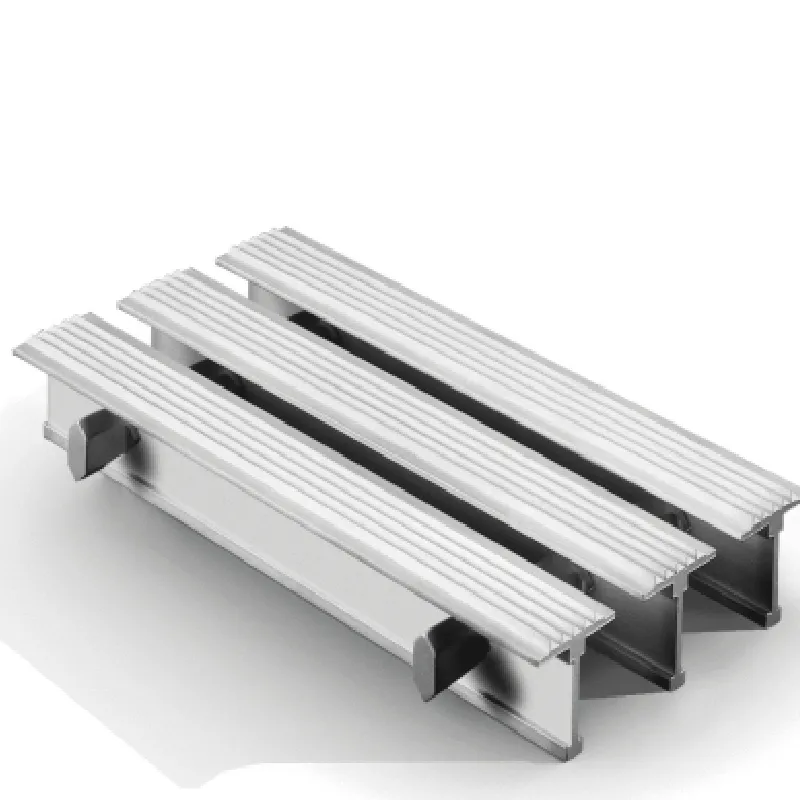

shale shaker screen price

5. Supplier Reputation and Support The reputation of the manufacturer or supplier can also influence pricing. Established companies with a track record of quality and customer service may charge a premium for their products. However, this can be worthwhile for clients seeking reliable support and warranties. Additionally, suppliers that offer comprehensive service agreements or maintenance packages may provide better value, offsetting their higher upfront costs over time.

Budgeting for Shale Shaker Screens

When budgeting for shale shaker screens, companies should consider both initial costs and long-term value. While a lower initial price may be appealing, it's crucial to evaluate the total cost of ownership, which includes replacement schedules, maintenance expenses, and the expected lifespan of the screens. Investing in higher-quality, more durable screens may lead to reduced downtime and overall cost savings.

Another important factor is to consider procurement strategies. Bulk purchases may provide significant discounts, and establishing long-term relationships with suppliers can result in better pricing and terms. Companies should engage with multiple suppliers to compare prices and understand the current market landscape.

Conclusion

In conclusion, the price of shale shaker screens is influenced by various factors, including material composition, design, market demand, size, and supplier reputation. Companies looking to purchase these screens should carefully evaluate their options, considering both immediate costs and long-term benefits. By understanding the key variables that affect pricing, buyers can make informed decisions that align with their operational needs and budgetary constraints, ultimately enhancing their drilling efficiency and effectiveness.

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024