- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

2 月 . 13, 2025 05:13

Back to list

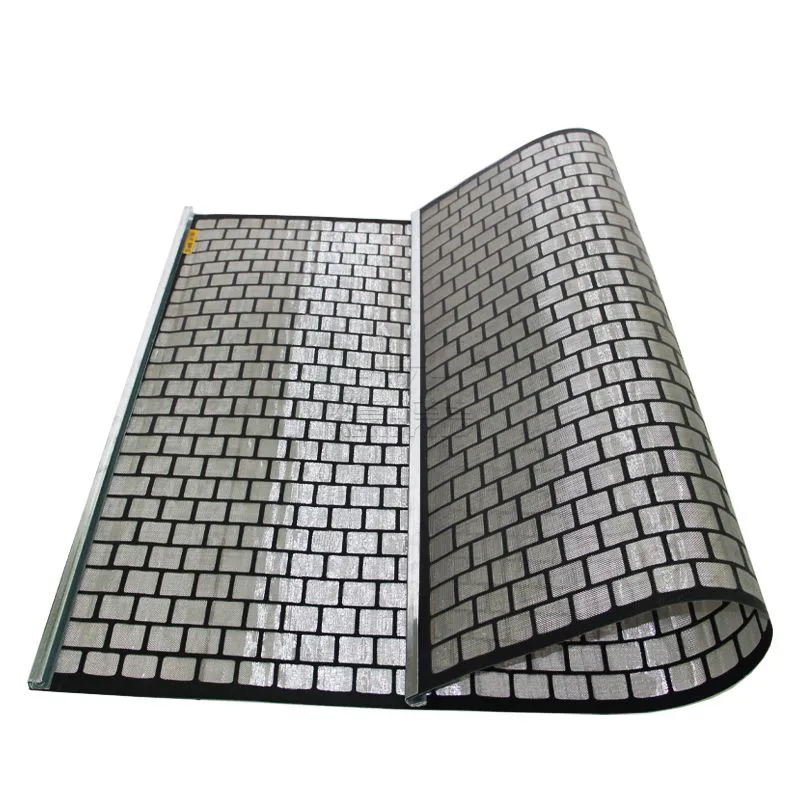

Shale Shaker Screen

Shale shaker screens are pivotal components in the oil and gas industry's drilling operations. As an integral part of the drilling fluid circulation system, these screens filter and remove solid particles from the drilling fluid, ensuring that only smaller particles pass through, thereby maintaining the efficiency and longevity of the operation. The choice of shale shaker screen mesh can significantly impact operational success and cost-effectiveness, necessitating a meticulous approach to selection and maintenance.

Trustworthiness in the realm of shale shaker screens is built through collaboration with reputable manufacturers renowned for their innovation and quality assurance processes. Manufacturers with established histories in the industry offer technical support and guidance tailored to specific operational needs. Engaging with these manufacturers ensures that not only are products of high quality procured, but expert insights into screen maintenance and optimization are also gained. This partnership is critical in today's competitive environment, where operational efficiency and cost management are key determinants of success. Diving into advanced shale shaker screen technologies, recent innovations have led to the development of screens with enhanced durability and filtration precision. Some screens now incorporate composite materials and innovative bonding techniques, reducing weight and enhancing resistance to mechanical pressures. These advances underscore the industry's trajectory towards more sustainable and efficient drilling practices. By adopting these cutting-edge solutions, operators stand to significantly increase their operational lifespan and minimize non-productive time. Ultimately, shale shaker screen mesh plays a crucial role in the safety and efficiency of drilling operations. Through diligent selection, adherence to industry standards, and leveraging reputable expertise, operators can greatly enhance their operational efficacy. By investing in high-quality shale shaker screens, companies not only safeguard their immediate operational effectiveness but also contribute to a more sustainable drilling environment reflective of modern energy demands.

Trustworthiness in the realm of shale shaker screens is built through collaboration with reputable manufacturers renowned for their innovation and quality assurance processes. Manufacturers with established histories in the industry offer technical support and guidance tailored to specific operational needs. Engaging with these manufacturers ensures that not only are products of high quality procured, but expert insights into screen maintenance and optimization are also gained. This partnership is critical in today's competitive environment, where operational efficiency and cost management are key determinants of success. Diving into advanced shale shaker screen technologies, recent innovations have led to the development of screens with enhanced durability and filtration precision. Some screens now incorporate composite materials and innovative bonding techniques, reducing weight and enhancing resistance to mechanical pressures. These advances underscore the industry's trajectory towards more sustainable and efficient drilling practices. By adopting these cutting-edge solutions, operators stand to significantly increase their operational lifespan and minimize non-productive time. Ultimately, shale shaker screen mesh plays a crucial role in the safety and efficiency of drilling operations. Through diligent selection, adherence to industry standards, and leveraging reputable expertise, operators can greatly enhance their operational efficacy. By investing in high-quality shale shaker screens, companies not only safeguard their immediate operational effectiveness but also contribute to a more sustainable drilling environment reflective of modern energy demands.

Share

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024