- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

shale shakerscreen manufacturers

Understanding Shale Shaker Screen Manufacturers

Shale shakers are pivotal components in the oil and gas drilling process, serving to separate drilling fluids from the cuttings generated during drilling. The effectiveness of a shale shaker heavily relies on the quality of its screens. Consequently, the role of shale shaker screen manufacturers is critical in ensuring operations run smoothly and efficiently.

Importance of Shale Shaker Screens

Shale shaker screens play an essential role in optimizing drilling performance. These screens filter out cuttings from the drilling fluid before it is circulated back into the wellbore. High-quality screens not only enhance drilling efficiency but also minimize the cost associated with drilling fluid losses and ensure better recovery of the cuttings. Manufacturers must focus on creating durable, high-capacity screens that can handle various environmental challenges and drilling conditions.

Key Features to Consider

When evaluating shale shaker screen manufacturers, several key features should be considered

1. Material Quality The best manufacturers utilize high-grade materials that offer strength and durability. Stainless steel and composite materials are often preferred for their resistance to wear and tear.

2. Technical Specifications The screen mesh size, tensioning system, and overall design need to align with the drilling requirements. Manufacturers should provide a variety of options to accommodate different drilling fluid types and conditions.

shale shakerscreen manufacturers

3. Cost-Effectiveness While it’s important to prioritize quality, the cost is also a significant factor for drilling companies. Efficient manufacturers balance quality with affordability, providing a range of products that fit different budgets without compromising performance.

4. Customization Every drilling operation may have unique requirements. Manufacturers that offer customizable solutions can better meet the specific needs of their clients, whether it involves adjusting mesh sizes or tailoring screen designs.

5. Technical Support Reliable manufacturers provide excellent customer service and technical support. This includes assistance with installation, maintenance, and troubleshooting to ensure optimal performance of shale shakers and screens.

Market Trends

The shale shaker screen manufacturing industry has seen various advancements in recent years. With the oil and gas sector continuously evolving, manufacturers are adopting innovative technologies to enhance the performance and lifespan of their products. Additionally, the growing trend towards environmentally friendly practices has prompted some manufacturers to explore eco-friendly materials in their screen production.

Conclusion

Selecting the right shale shaker screen manufacturer is crucial for achieving efficient and effective drilling operations. High-quality screens can significantly impact the overall success of drilling projects by optimizing fluid recovery and reducing costs associated with material losses. As the industry progresses, manufacturers that embrace innovation while maintaining standards of quality and customer service will stand out in a competitive market. For drilling companies, making informed choices based on these parameters can lead to better performance and ultimately a more successful drilling operation.

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

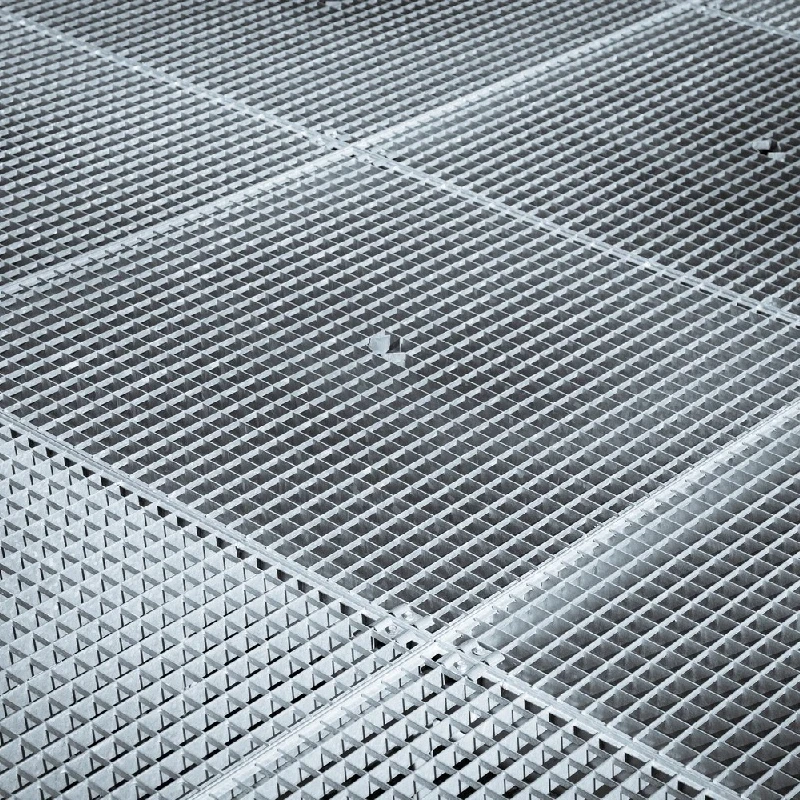

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024