- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

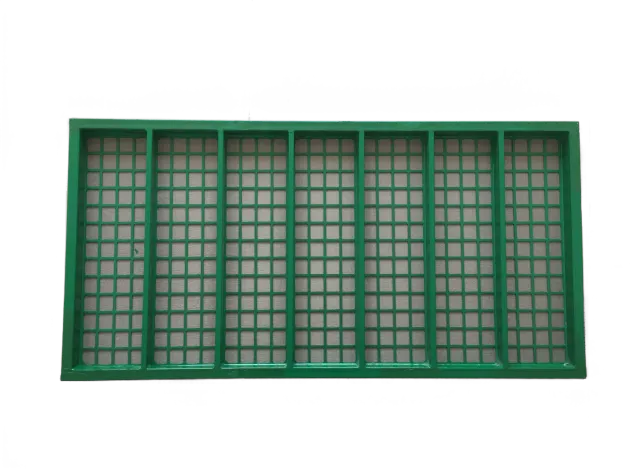

High-Quality Shale Shaker Screens Available for Purchase and Immediate Delivery

Shale Shaker Screens for Sale Essential Tools in the Oil and Gas Industry

In the oil and gas industry, the efficiency of drilling operations heavily relies on the quality of equipment used, especially when it comes to the management of drilling fluids. One of the most critical components in this process is the shale shaker screen. With the growing demand for shale shaker screens, it’s important to understand what they are, their purpose in drilling, and the factors to consider when purchasing them.

What is a Shale Shaker Screen?

A shale shaker screen is a vital part of a shale shaker, which is a machine used to separate drilling cuttings from the drilling fluid as it circulates during drilling operations. The screens are designed to allow the fluid to pass through while retaining the solid particles. This not only helps in recycling valuable drilling fluids but also maintains the desired properties of the drilling mud, ensuring optimal drilling performance.

Importance of Shale Shaker Screens

The primary role of shale shaker screens is to enhance the efficiency of the drilling process. By effectively separating cuttings from the drilling fluid, these screens help in reducing downtime and minimizing fluid loss. Properly functioning screens lead to a more efficient drilling operation, which ultimately results in cost savings for oil and gas companies. Moreover, high-quality screens can significantly extend the life of the shale shaker, reducing the need for frequent replacements and repairs.

Types of Shale Shaker Screens

Shale shaker screens come in various types, including woven mesh screens, perforated plates, and synthetic screens. Woven mesh screens are made from stainless steel and are designed for durability and strength, providing excellent performance in various drilling environments. Perforated plates, on the other hand, are more rigid and suitable for larger solid particles. Synthetic screens are made from high-tech materials and are known for their ability to withstand harsh conditions while providing high-capacity throughput.

Factors to Consider When Buying Shale Shaker Screens

shale shaker screen for sale

When looking for shale shaker screens for sale, several factors should be taken into consideration to ensure you make the right choice

1. Material Quality The material of the screen affects its lifespan and performance. High-quality stainless steel or advanced synthetic materials are preferable for enhanced durability.

2. Mesh Size The mesh size determines the screen's filtering capability. It's essential to choose the right mesh size based on the type of drilling operation and the nature of the cuttings.

3. Screen Configuration Screens are available in different configurations, such as flat and pyramid-shaped. The choice of configuration can impact its effectiveness in different drilling conditions.

4. Compatibility Ensure that the screens are compatible with the specific shale shaker model you are using. Compatibility reduces the risk of malfunction and enhances overall performance.

5. Manufacturer Reputation Consider purchasing from reputable manufacturers who offer warranties and after-sales support. A strong reputation often indicates quality and reliability.

Conclusion

Investing in high-quality shale shaker screens is essential for any oil and gas operation that aims to maintain efficiency and productivity. With various options available for sale, it is crucial to understand the specific needs of your drilling operations and choose screens that meet those requirements. As the demand for oil and gas continues to rise, ensuring efficient drilling processes through the use of the right equipment, including shale shaker screens, will remain a priority in the industry.

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024