- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

1 月 . 20, 2025 15:07

Back to list

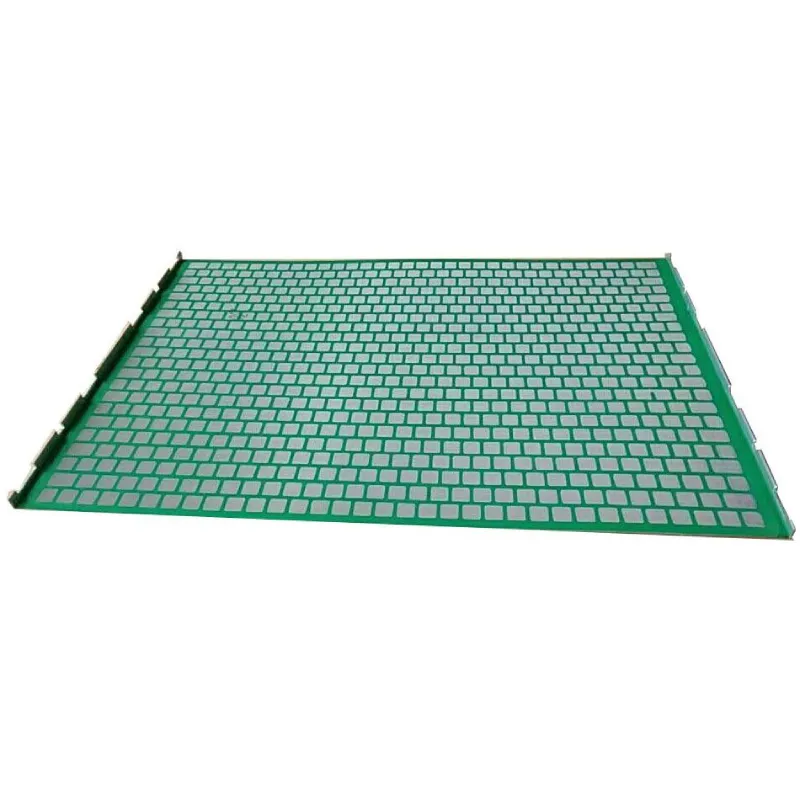

Shale Shaker Screen

In the world of oil and gas drilling, the shale shaker screen acts as an unsung hero, pivotal in separating solids from liquids in the drilling fluid. The efficiency of this essential tool directly impacts the operational effectiveness of drilling projects, emphasizing the importance of investing in high-quality shale shaker screens for optimal performance. Understanding the nuances of shale shaker screen manufacturing is crucial for drilling enterprises aiming to elevate their operations, making the choice of a reliable shale shaker screen factory paramount.

In addition, the integration of technology in manufacturing processes epitomizes the factory's commitment to innovation. Incorporating state-of-the-art machinery, such as automated welding systems and precision laser cutting, ensures high precision and reduces human error. The resulting screens exhibit uniform quality and precise dimensions, translating to better fitment and efficiency in field operations. This technological edge further cements the factory’s authoritative role as a pioneer in the industry. Environmental considerations also play a significant role in the operational ethos of a reputable shale shaker screen factory. The implementation of eco-friendly practices, such as the utilization of recyclable materials and waste minimization techniques, underscores the factory's responsibility towards sustainable manufacturing. These practices resonate with environmentally-conscious enterprises within the oil and gas sector, thereby enhancing the factory's reputation and trustworthiness. A comprehensive understanding of a factory's after-sale service framework provides insight into its dedication to clients' success. By offering robust support services, including prompt delivery, installation guidance, and ongoing technical support, these factories build lasting relationships with their clients, further enhancing customer satisfaction and reinforcing the factory's credibility. In conclusion, a shale shaker screen factory embodies the synergy of experience, expertise, authoritativeness, and trustworthiness expected by industry professionals. Such a factory not only supplies a vital product but also serves as a partner in enhancing operational success through innovative, reliable, and sustainable manufacturing practices. As drilling operations continue to evolve, the role of such a factory remains integral, driving progress and efficiency within the oil and gas sector.

In addition, the integration of technology in manufacturing processes epitomizes the factory's commitment to innovation. Incorporating state-of-the-art machinery, such as automated welding systems and precision laser cutting, ensures high precision and reduces human error. The resulting screens exhibit uniform quality and precise dimensions, translating to better fitment and efficiency in field operations. This technological edge further cements the factory’s authoritative role as a pioneer in the industry. Environmental considerations also play a significant role in the operational ethos of a reputable shale shaker screen factory. The implementation of eco-friendly practices, such as the utilization of recyclable materials and waste minimization techniques, underscores the factory's responsibility towards sustainable manufacturing. These practices resonate with environmentally-conscious enterprises within the oil and gas sector, thereby enhancing the factory's reputation and trustworthiness. A comprehensive understanding of a factory's after-sale service framework provides insight into its dedication to clients' success. By offering robust support services, including prompt delivery, installation guidance, and ongoing technical support, these factories build lasting relationships with their clients, further enhancing customer satisfaction and reinforcing the factory's credibility. In conclusion, a shale shaker screen factory embodies the synergy of experience, expertise, authoritativeness, and trustworthiness expected by industry professionals. Such a factory not only supplies a vital product but also serves as a partner in enhancing operational success through innovative, reliable, and sustainable manufacturing practices. As drilling operations continue to evolve, the role of such a factory remains integral, driving progress and efficiency within the oil and gas sector.

Share

Prev:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024