- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Impact of Shale Screen on Oil Production Efficiency and Environmental Sustainability

The Role of Shale Screens in Modern Oil and Gas Exploration

In the constantly evolving landscape of the oil and gas industry, innovative technologies play a crucial role in enhancing efficiency and maximizing resource extraction. One such advancement that has gained prominence is the use of shale screens. These specialized tools are designed to optimize the exploration and extraction of hydrocarbons from shale formations, contributing significantly to the overall productivity and sustainability of resource harvesting.

Understanding Shale Screens

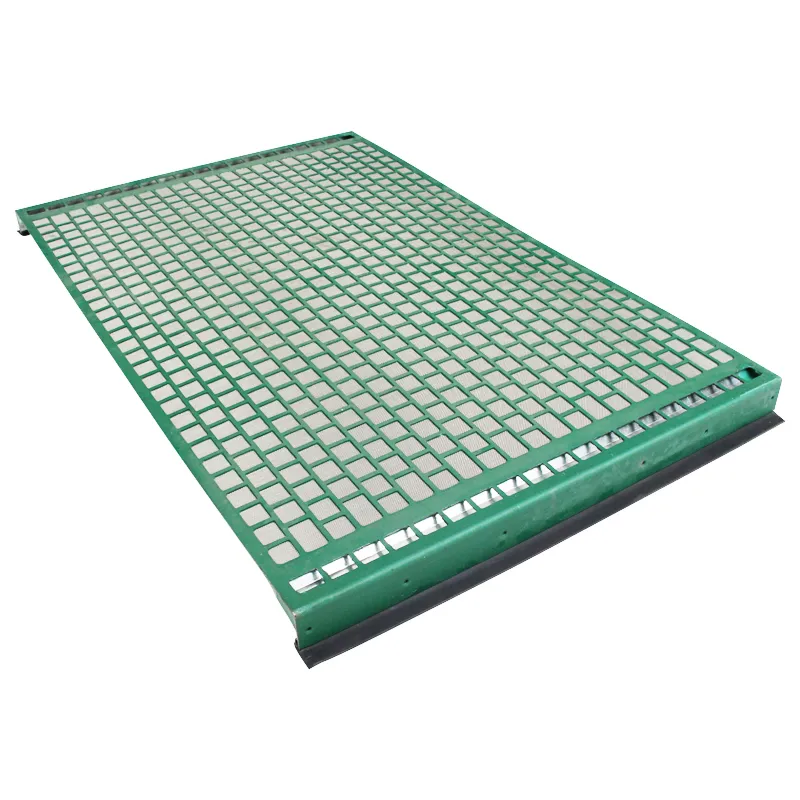

Shale screens are porous materials used primarily in the separation and filtration processes during the extraction of shale gas and oil. They serve multiple functions, including the protection of equipment from solid particulates, the enhancement of fluid flow, and the maintenance of wellbore stability. The development of shale screens has been driven by the unique challenges presented by shale formations, which differ greatly from conventional oil reservoirs.

These screens function by allowing fluids to pass through while filtering out unwanted solid materials that can impede the extraction process. Materials commonly used in the manufacturing of shale screens include advanced polymers, metals, and composite materials that offer high strength, flexibility, and resistance to harsh operational environments.

Importance in Hydraulic Fracturing

One of the primary applications of shale screens is in hydraulic fracturing (fracking), a technique used to enhance the flow of natural gas and oil from shale formations. During fracking, a high-pressure fluid is injected into the wellbore to fracture the rock, creating pathways for hydrocarbons to flow more freely. Shale screens play a critical role in this process by preventing the clogging of the wellbore with debris generated during fracturing.

By maintaining optimal wellbore conditions, shale screens facilitate better extraction rates and reduce the need for costly interventions

. Furthermore, the use of these screens can help mitigate environmental impacts by minimizing the need for excessive water use and chemical additives, which are common concerns associated with hydraulic fracturing.shale screen

Enhancing Resource Recovery

The integration of shale screens into oil and gas extraction operations not only improves efficiency but also enhances resource recovery rates. By effectively separating solids from fluids, shale screens enable operators to maximize the volume of recoverable hydrocarbons while minimizing waste. This is particularly important in shale plays where resource deposits can be challenging to access and require sophisticated technology to extract economically.

Moreover, the ability to customize shale screens for specific formation characteristics allows for targeted extraction strategies that can adapt to varying geological conditions. This tailored approach not only improves profitability but also helps ensure more sustainable practices within the industry.

Challenges and Innovations

Despite their benefits, the use of shale screens is not without challenges. Issues such as screen wear and tear, clogging, and the effectiveness of different materials have prompted ongoing research and development. Innovations in screen design, such as the introduction of self-cleaning mechanisms and nano-coatings, are currently being explored to enhance durability and performance.

The future of shale screens also looks promising with advancements in technology such as artificial intelligence and machine learning. These tools can predict the wear patterns of screens in real-time, enabling operators to conduct proactive maintenance and reduce downtime.

Conclusion

The evolving role of shale screens in oil and gas exploration underscores the significance of innovative technologies in improving resource extraction efficiency. As the global demand for energy continues to rise, the implementation of advanced extraction techniques such as shale screens represents a crucial step towards achieving sustainable practices within the industry. As research continues and new materials and technologies are developed, the future of shale screens will likely include even more sophisticated solutions that can address the challenges of modern extraction while promoting environmental responsibility. In this way, shale screens not only enhance productivity but also pave the way for a more sustainable energy future.

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024