- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

shaker screens

Understanding Shaker Screens A Key Component in the Filtration Process

Shaker screens are integral components in various industrial processes, particularly in the fields of mining, oil and gas, and construction. These screens are primarily designed to facilitate the separation of different materials by size, ensuring that operations run smoothly and efficiently.

At its core, a shaker screen is a mesh or fabric material stretched over a frame that vibrates to aid in the sorting and classification of materials. The vibrating motion not only enhances the efficiency of the screening process but also reduces the time required to achieve the desired separation. The fundamental principle behind shaker screens is relatively simple as materials feed onto the surface of the screen, the vibration causes smaller particles to pass through the screen while larger particles remain on top. This results in a more effective sorting process compared to static screens.

In the mining industry, shaker screens play a critical role in the processing of ore. After the initial crushing of ore, shaker screens are employed to separate fine particles from larger fragments. This process ensures that only the desired sizes proceed to subsequent processing stages, such as washing or concentration. By utilizing shaker screens, mining operations can improve yield, reduce waste, and ultimately lower costs.

In the oil and gas industry, shaker screens are commonly used in the drilling phase, where drilling mud is circulated to cool the drill bit and remove cuttings from the borehole. During this process, shaker screens separate the solid particles from the drilling fluid to maintain its properties. The efficiency of this screening process directly impacts well productivity and cost-effectiveness. Shaker screens must be robust enough to handle the abrasive nature of drilling fluids while allowing for easy cleaning and maintenance.

shaker screens

The design of shaker screens has seen significant advancements over the years

. Traditional metal mesh screens have been largely replaced by new materials that offer higher durability and efficiency. For example, polyurethane and composite materials are now commonly used due to their resistance to wear and chemical corrosion. These modern materials not only improve the lifespan of the screens but also enhance their performance in various operational conditions.Moreover, technological advancements have introduced innovative features into shaker screens. For example, some screens incorporate adjustable vibration frequencies, allowing operators to optimize the settings for different material types and sizes. This flexibility ensures that operations can be tailored to meet specific production needs, thereby maximizing efficiency.

In addition to their essential role in mining and drilling, shaker screens are also employed in construction and waste management. In recycling operations, for instance, shaker screens are used to separate recyclable materials from waste. This process is crucial for promoting sustainability and reducing landfill usage. Similarly, in construction, shaker screens help in the separation of aggregates to meet specifications for various building materials.

The efficiency of shaker screens is not solely attributed to their design and materials; proper installation and maintenance also play a significant role in their performance. Regular inspections and timely replacements of worn-out screens are necessary to prevent operational downtime and maintain optimal efficiency. Furthermore, training operators on the appropriate use of shaker screens ensures that they can make real-time adjustments to enhance performance based on the characteristics of the materials being processed.

In conclusion, shaker screens serve as a vital mechanism in various industrial processes by facilitating effective material separation. Their applications span multiple sectors, including mining, oil and gas, construction, and waste management. As technology continues to evolve, so too will the design and functionality of shaker screens, further enhancing their role in optimizing production efficiency and supporting sustainable practices. The investment in high-quality shaker screens and proper maintenance protocols will ultimately translate into improved operational outcomes and reduced costs for businesses across these industries.

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

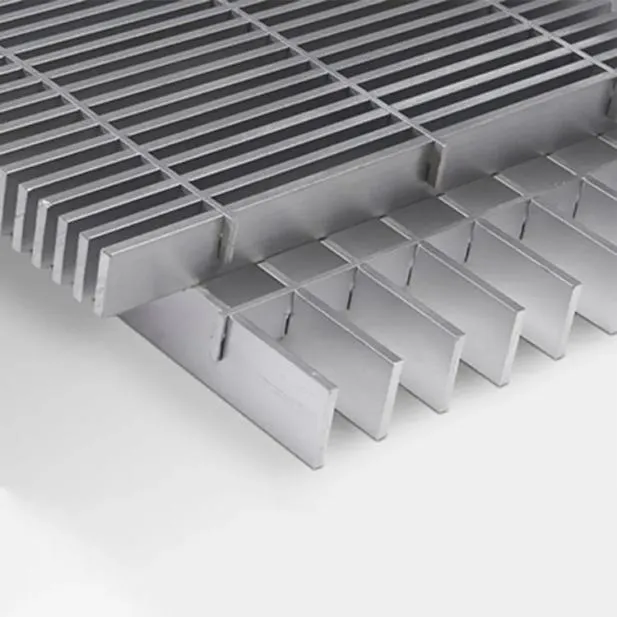

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024