- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

2 月 . 10, 2025 20:58

Back to list

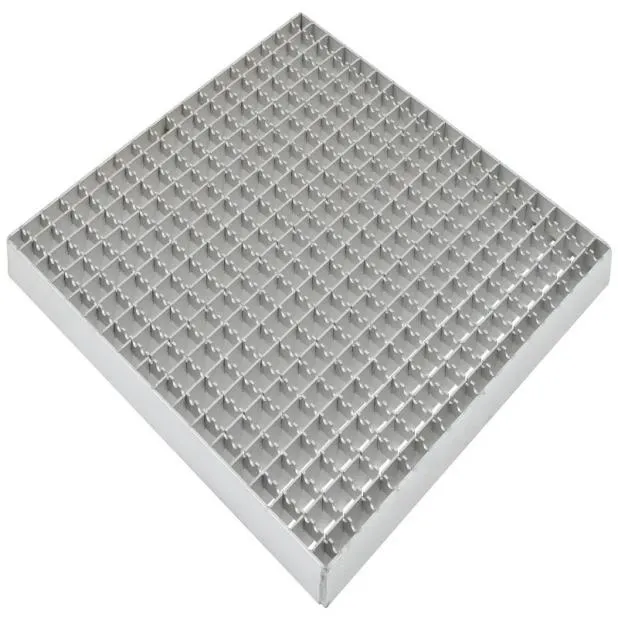

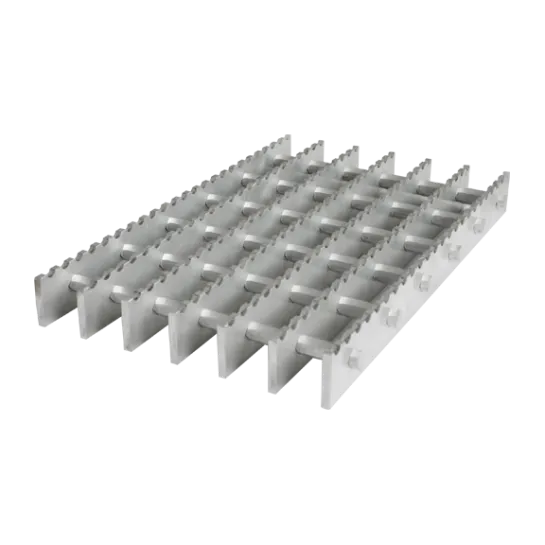

Press-Locked Steel Grating

Serrated steel grating has emerged as an essential component in various industrial applications, promising a blend of safety and durability. For those who prioritize top-tier materials in construction or industrial maintenance, this grating offers multiple advantages unrivaled by traditional flooring solutions. Understanding the unique properties and applications of serrated steel grating could enhance both safety measures and operational efficiency in your projects.

When sourcing serrated steel grating, it is crucial to consider the expertise and credibility of the manufacturer. Reliable suppliers will offer gratings that meet or exceed industry standards. They would typically provide detailed specifications and certifications, guaranteeing that their products adhere to the highest safety and quality benchmarks. Seek suppliers with substantial experience in the industry, as they are more likely to have honed the manufacturing processes and can offer valuable insights into the best grating solutions for specific applications. Moreover, sustainability practices are becoming increasingly important in construction and industrial projects. Choosing serrated steel grating from manufacturers committed to eco-friendly production processes helps reduce the environmental impact of your projects. Some manufacturers now use recycled materials in their production of steel grating, illustrating a commitment to sustainability. In conclusion, serrated steel grating serves as an effective solution for those seeking to enhance safety and efficiency in challenging industrial environments. Its anti-slip properties, durability, and low maintenance requirements make it an invaluable asset across various sectors. By choosing products from reputable manufacturers, companies can ensure high-quality installations that comply with both safety and environmental standards. As industries continue to prioritize safety and sustainability, serrated steel grating stands out as a forward-thinking choice that aligns with these values while delivering exceptional performance.

When sourcing serrated steel grating, it is crucial to consider the expertise and credibility of the manufacturer. Reliable suppliers will offer gratings that meet or exceed industry standards. They would typically provide detailed specifications and certifications, guaranteeing that their products adhere to the highest safety and quality benchmarks. Seek suppliers with substantial experience in the industry, as they are more likely to have honed the manufacturing processes and can offer valuable insights into the best grating solutions for specific applications. Moreover, sustainability practices are becoming increasingly important in construction and industrial projects. Choosing serrated steel grating from manufacturers committed to eco-friendly production processes helps reduce the environmental impact of your projects. Some manufacturers now use recycled materials in their production of steel grating, illustrating a commitment to sustainability. In conclusion, serrated steel grating serves as an effective solution for those seeking to enhance safety and efficiency in challenging industrial environments. Its anti-slip properties, durability, and low maintenance requirements make it an invaluable asset across various sectors. By choosing products from reputable manufacturers, companies can ensure high-quality installations that comply with both safety and environmental standards. As industries continue to prioritize safety and sustainability, serrated steel grating stands out as a forward-thinking choice that aligns with these values while delivering exceptional performance.

Share

Next:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024