- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

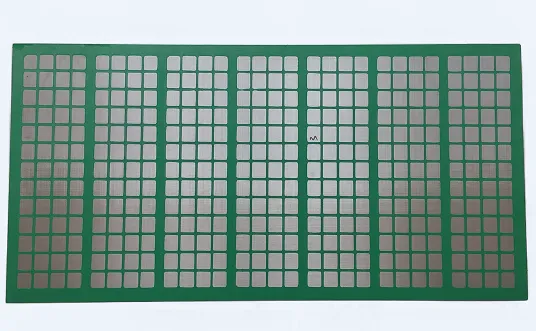

serrated steel bar grating

Serrated Steel Bar Grating A Comprehensive Overview

In the realm of industrial flooring and access solutions, serrated steel bar grating has emerged as a vital component due to its unique characteristics and versatile applications. Comprised of a series of parallel steel bars, this form of grating is designed specifically for strength, durability, and safety in various environments. This article delves into the features, benefits, applications, and maintenance of serrated steel bar grating, providing a comprehensive understanding of why it is increasingly favored across diverse industries.

What Is Serrated Steel Bar Grating?

Serrated steel bar grating is constructed from flat steel bars that are welded together in a series, creating a grid-like structure. The key distinguishing feature of serrated grating is the presence of grooves or serrations along the bar's surface. These serrations provide enhanced traction, making it significantly safer for foot traffic, especially in environments where spills or wet conditions may occur.

The grating is typically galvanized or coated with a protective finish, which enhances its resistance to corrosion and prolongs its lifespan. The combination of steel's inherent strength and the added traction from the serrated design makes this grating ideal for industrial applications where durability and safety are paramount.

Benefits of Serrated Steel Bar Grating

1. Enhanced Traction The primary advantage of serrated steel bar grating is its ability to provide superior grip, reducing slip-and-fall accidents in workplaces. This is particularly important in environments such as factories, chemical plants, and outdoor platforms where spills can occur.

2. Load-Bearing Capacity Serrated grating is engineered to support heavy loads, making it suitable for use in industrial settings where equipment and heavy machinery are present. Its structural integrity allows it to withstand significant weight without compromising safety.

3. Durability Steel is renowned for its strength and longevity. When treated with galvanization or coatings, serrated steel grating can resist wear from foot traffic, harsh chemicals, and environmental factors, ensuring a long service life.

4. Versatility This type of grating can be fabricated in various sizes, thicknesses, and bar spacing, making it adaptable to a wide range of applications. Whether used in walkways, catwalks, platforms, or drainage covers, serrated steel bar grating can meet specific design requirements.

5. Minimal Maintenance The robust nature of steel grating means that it often requires minimal maintenance compared to other flooring options. Regular inspections and occasional cleaning are usually sufficient to maintain its functionality and appearance.

Applications of Serrated Steel Bar Grating

serrated steel bar grating

Serrated steel bar grating finds applications in multiple sectors, including

- Industrial Facilities Used extensively in manufacturing plants, warehouses, and processing facilities, it provides safe and reliable flooring for employees and equipment.

- Transportation It is commonly found in pedestrian walkways, bridges, and bus or train stations, ensuring safety for commuters.

- Civic Projects Serrated grating can be utilized in parks, environmental projects, and public spaces to create safe and accessible areas for the community.

- Chemical and Oil & Gas Sectors Its resistance to corrosion and ability to handle heavy loads make it indispensable in refineries and chemical processing plants.

Maintenance Considerations

While serrated steel bar grating is low-maintenance, regular checks should be performed to ensure that it remains in good condition. Key maintenance practices include

- Visual Inspections Regularly inspect for any signs of wear, corrosion, or loosening of welds to ensure safety.

- Cleaning Depending on its location, grating may accumulate debris, oil, or contaminants. Regular cleaning helps maintain traction and reduce slip hazards.

- Rust Prevention For outdoor applications, especially in coastal areas or regions with high humidity, proactive measures such as applying rust inhibitors can help maintain the grating’s integrity.

Conclusion

In summary, serrated steel bar grating stands out as a reliable solution for flooring and access needs across various industries. Its combination of safety features, strength, and versatility makes it a preferred choice for both industrial and civic applications. By investing in high-quality serrated grating and adhering to routine maintenance practices, companies can ensure the safety and efficiency of their operational environments while minimizing long-term costs.

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024