- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Weight Considerations for Serrated Grating in Structural Applications and Design Optimization

Understanding Serrated Grating Weight An Overview

Serrated grating, a vital component in various engineering and architectural applications, has garnered increasing attention due to its unique design, which combines functionality with aesthetic appeal. The weight of serrated grating is an essential factor influencing its application, performance, and overall structural integrity. This article delves into the aspects influencing serrated grating weight, its significance, and considerations for choosing the right type for specific projects.

What is Serrated Grating?

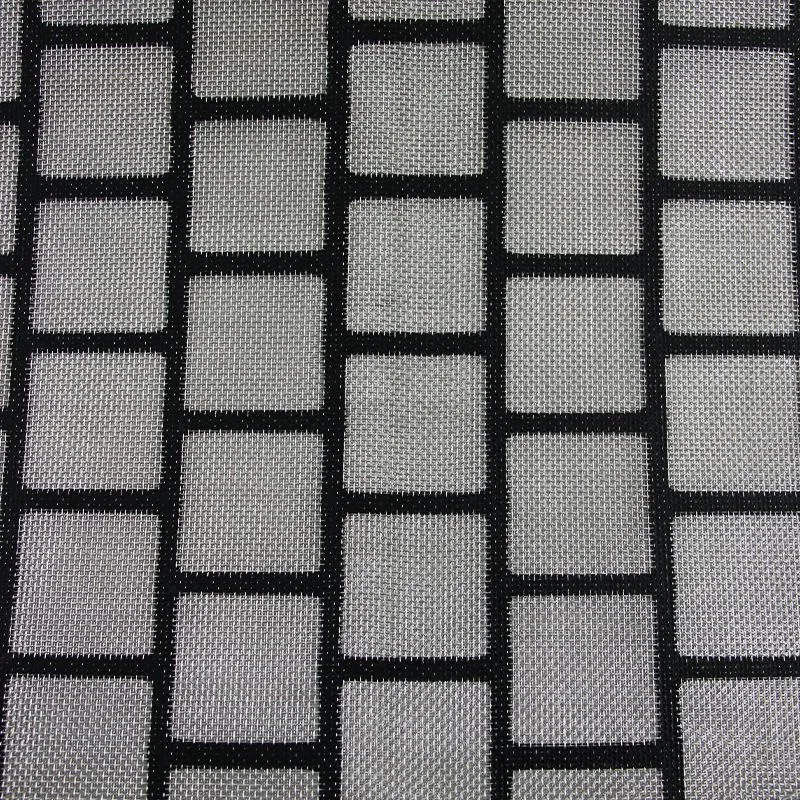

Serrated grating refers to a type of metal grating characterized by its notched surface, designed to provide improved traction and slip resistance. It is commonly made from materials such as steel, aluminum, and fiberglass, making it suitable for various environments, ranging from industrial facilities to pedestrian walkways. The serrated design enhances safety, especially in wet or slippery conditions, while also allowing for effective drainage as water flows through the openings.

Factors Affecting Weight

The weight of serrated grating is influenced by several factors

1. Material Type The choice of material is perhaps the most significant determinant of grating weight. Steel is heavier than aluminum but offers superior strength and durability. In contrast, fiberglass is lighter and resistant to corrosion, making it suitable for specific applications but may not bear heavy loads.

2. Bar Size and Configuration Serrated gratings come in varying bar sizes and configurations. The thickness and width of the bars directly impact the weight. Heavier and thicker bars will naturally result in a heavier grating solution, which may be required for high-load applications.

serrated grating weight

3. Spacing The spacing between the bars also affects the overall weight. Closer spacing can provide better support and load distribution, leading to a heavier grating. However, changing the spacing must consider the required strength and security against potential loads.

4. Manufacturing Process The method by which the grating is produced can also affect its weight. For example, welded grating may carry different weights compared to pressed grating, depending on the structural integrity and processing techniques used.

Importance of Weight Consideration

The weight of serrated grating plays a crucial role in its application across various industries. In construction, knowing the weight is essential for structural calculations to ensure that the supporting frameworks can handle the load. Furthermore, when designing installations, understanding the weight helps in determining the appropriate handling and transportation methods.

In addition to structural considerations, weight also impacts installation procedures. Lighter grating can be easier to handle and install, reducing labor costs and time. Conversely, heavier grates may require special equipment or additional manpower for safe installation.

Conclusion

In conclusion, the weight of serrated grating is a fundamental aspect that must be carefully considered during the design and planning stages of any project. Understanding the factors that affect weight—including material type, bar size, spacing, and manufacturing processes—enables engineers and architects to select the most suitable options for their specific applications. As industries continue to advance, the emphasis on safety, durability, and aesthetic appeal will make serrated grating an increasingly pivotal component in structural design. Whether for industrial use or public spaces, the right choice of serrated grating can enhance both functionality and safety while contributing to the overall success of a project.

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024