- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

1 月 . 30, 2025 03:18

Back to list

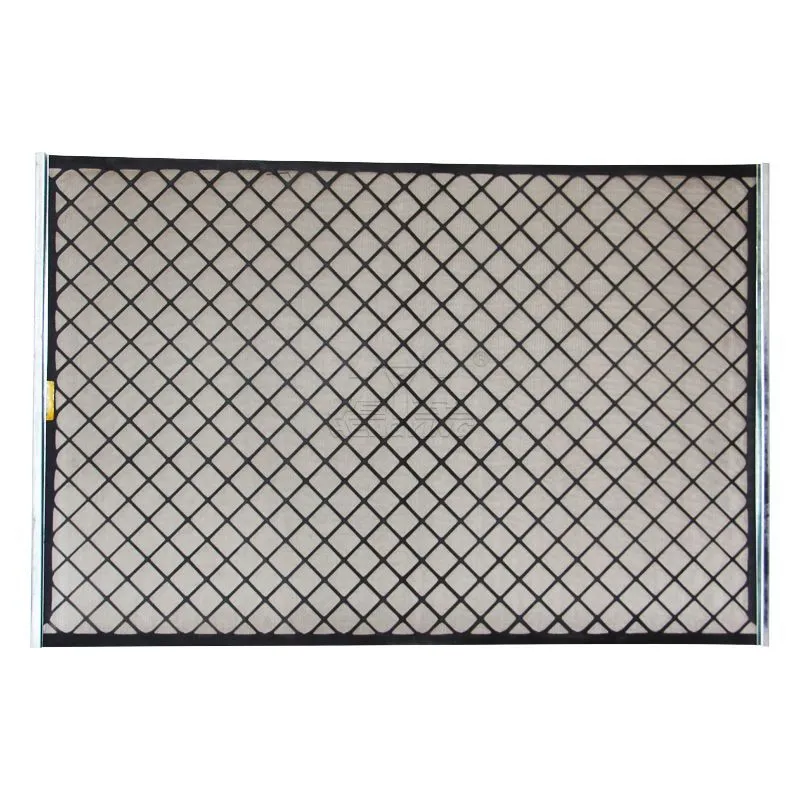

serrated steel grating

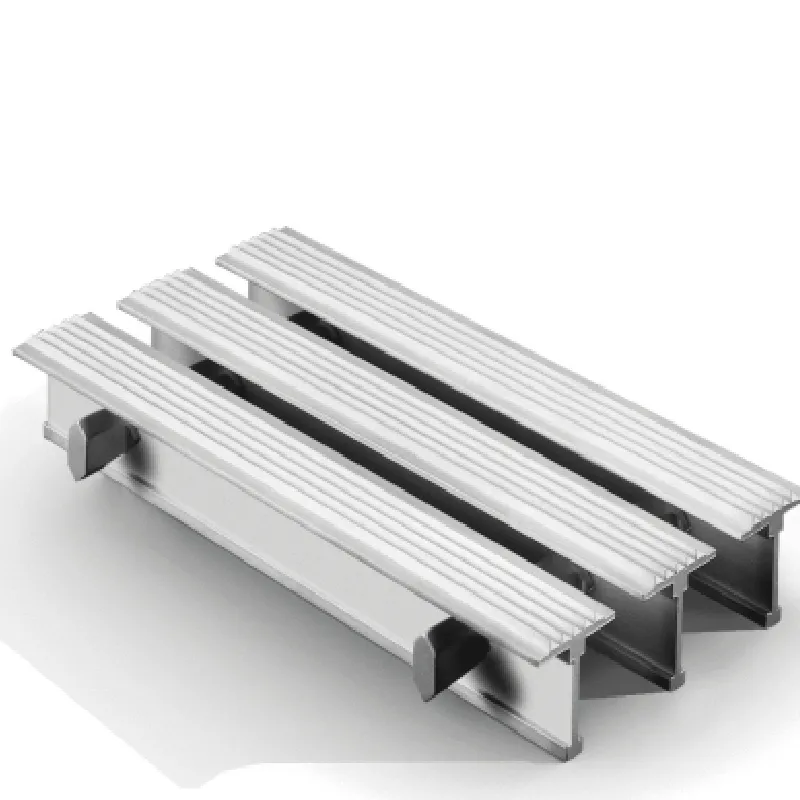

Serrated galvanized grating stands as an essential material in various industrial and commercial applications, offering both durability and safety. These gratings consist of a series of metal bars, commonly steel, forming a grid-like pattern that is enhanced with a serrated surface, providing excellent slip resistance. Furthermore, the galvanization process involves a zinc coating that offers exceptional protection against corrosion, making it suitable for both indoor and outdoor usage.

Trustworthiness is another pillar supporting the widespread use of serrated galvanized grating. Given its substantial role in public infrastructure projects, such as pedestrian bridges and transit systems, its reliability is often backed by rigorous industry standards and certifications. Manufacturers conduct thorough testing, ensuring that each batch meets international safety and performance benchmarks, thus affirming user confidence. A practical tip for businesses considering an investment in serrated galvanized grating is to assess their specific load and environmental needs. Selecting the appropriate thickness and bar spacing can result in significant cost savings and enhanced performance. It's advisable to consult with reputable suppliers who can provide customized solutions tailored to your specific project requirements. In the broader landscape of industrial materials, serrated galvanized grating represents a synergy of innovation and practicality. Its combination of safety, durability, and cost-effectiveness makes it an attractive option across various sectors. Future advancements may include exploring eco-friendly galvanization processes and incorporating advanced alloys for even greater performance, keeping in line with global sustainability goals. In conclusion, serrated galvanized grating embodies a sophisticated blend of functionality and reliability essential for modern infrastructure. Whether for safety or durability, its application across diverse industries attests to its enduring value. Consequently, businesses and experts alike continue to favor it as a trusted solution for challenging environments.

Trustworthiness is another pillar supporting the widespread use of serrated galvanized grating. Given its substantial role in public infrastructure projects, such as pedestrian bridges and transit systems, its reliability is often backed by rigorous industry standards and certifications. Manufacturers conduct thorough testing, ensuring that each batch meets international safety and performance benchmarks, thus affirming user confidence. A practical tip for businesses considering an investment in serrated galvanized grating is to assess their specific load and environmental needs. Selecting the appropriate thickness and bar spacing can result in significant cost savings and enhanced performance. It's advisable to consult with reputable suppliers who can provide customized solutions tailored to your specific project requirements. In the broader landscape of industrial materials, serrated galvanized grating represents a synergy of innovation and practicality. Its combination of safety, durability, and cost-effectiveness makes it an attractive option across various sectors. Future advancements may include exploring eco-friendly galvanization processes and incorporating advanced alloys for even greater performance, keeping in line with global sustainability goals. In conclusion, serrated galvanized grating embodies a sophisticated blend of functionality and reliability essential for modern infrastructure. Whether for safety or durability, its application across diverse industries attests to its enduring value. Consequently, businesses and experts alike continue to favor it as a trusted solution for challenging environments.

Share

Prev:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024