- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

1 月 . 28, 2025 05:12

Back to list

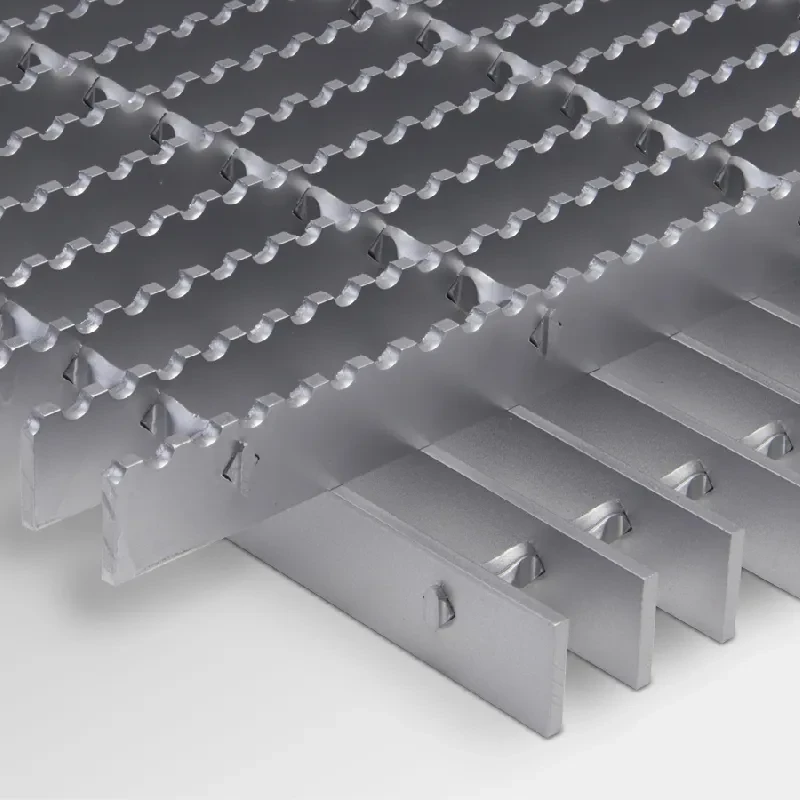

Press-Locked Steel Grating

In the world of industrial flooring solutions, serrated bar grating is a product that stands out for its unique combination of durability, safety, and functionality. Serrated bar grating, often utilized in environments where slip resistance is paramount, offers the perfect balance between robust build and practical design. Known for its serrated edges that provide exceptional grip, this type of grating is predominantly seen in applications ranging from walkways and mezzanines to platforms and stair treads in both commercial and industrial settings.

Installation is another strong suit of serrated bar grating, boasting a straightforward process that can be adapted to a wide range of scenarios without the necessity of specialized tools or in-depth training. This ease of installation further reduces total project time and labor costs, making it an economically smart choice for both retrofits and new projects. Moreover, its versatile nature allows for customization in terms of size and support carrying capacity, making it suitable for both heavy-duty and light-load environments without compromising on safety. Expert recommendations suggest choosing grating that fits precisely within the intended layout, as tight seams enhance its structural integrity and aesthetic appeal. In addition to industrial applications, serrated bar grating is finding its way into modern architectural design owing to its sleek appearance and functionality. Designers are increasingly integrating it into aesthetic structures, such as rooftop garden pathways or high-rise escape routes, effectively combining form and function. In conclusion, serrated bar grating represents a superior choice for industries focused on safety and efficiency. Its performance in terms of grip and durability is concrete evidence of its value addition to any infrastructure project. Its adoption denotes a brand's commitment to safety and adherence to industrial standards, reflecting reliability and authority. Therefore, partnering with trusted manufacturers ensures a product that stands up to scrutiny in both functional and safety parameters, aligning with the core principles of experience, expertise, authoritativeness, and trustworthiness.

Installation is another strong suit of serrated bar grating, boasting a straightforward process that can be adapted to a wide range of scenarios without the necessity of specialized tools or in-depth training. This ease of installation further reduces total project time and labor costs, making it an economically smart choice for both retrofits and new projects. Moreover, its versatile nature allows for customization in terms of size and support carrying capacity, making it suitable for both heavy-duty and light-load environments without compromising on safety. Expert recommendations suggest choosing grating that fits precisely within the intended layout, as tight seams enhance its structural integrity and aesthetic appeal. In addition to industrial applications, serrated bar grating is finding its way into modern architectural design owing to its sleek appearance and functionality. Designers are increasingly integrating it into aesthetic structures, such as rooftop garden pathways or high-rise escape routes, effectively combining form and function. In conclusion, serrated bar grating represents a superior choice for industries focused on safety and efficiency. Its performance in terms of grip and durability is concrete evidence of its value addition to any infrastructure project. Its adoption denotes a brand's commitment to safety and adherence to industrial standards, reflecting reliability and authority. Therefore, partnering with trusted manufacturers ensures a product that stands up to scrutiny in both functional and safety parameters, aligning with the core principles of experience, expertise, authoritativeness, and trustworthiness.

Share

Next:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024