- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

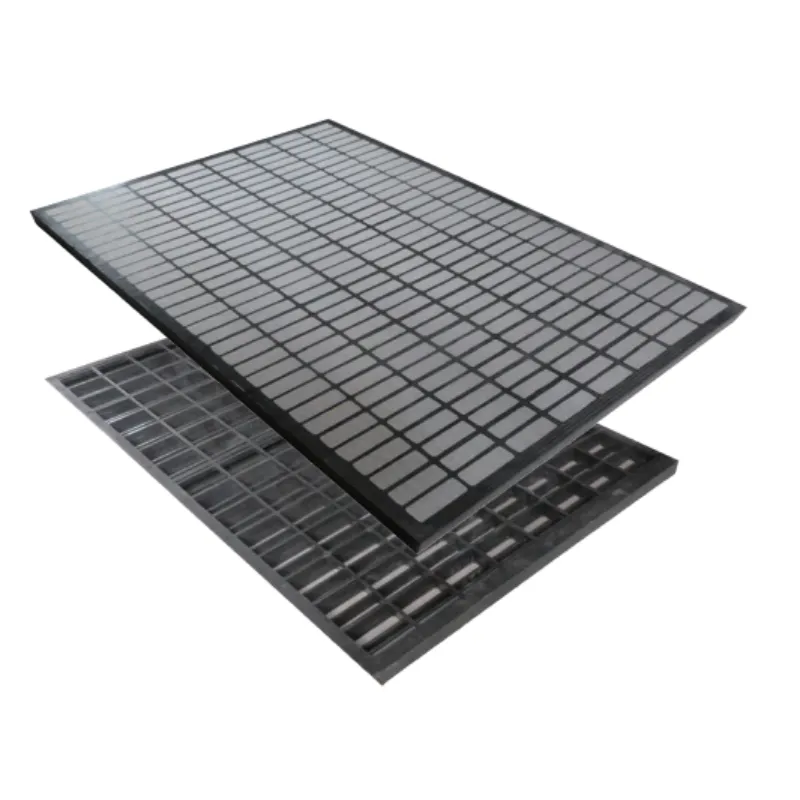

serrated bar grate

The Advantages of Serrated Bar Grates in Modern Applications

In today's industrial landscape, efficiency and safety are paramount. Whether in manufacturing, food processing, or construction, the choice of materials and designs can significantly impact productivity and performance. One such innovation that has garnered attention is the serrated bar grate. This unique design integrates functionality with safety, making it an essential element in various applications.

Understanding Serrated Bar Grates

Serrated bar grates are specialized platforms made of elongated bars with serrated edges. These grates are typically constructed from robust materials like stainless steel, carbon steel, or aluminum, offering durability and resistance to wear and corrosion. The serration in the bars aids in enhancing the grip and preventing slips, making them ideal for environments where safety is a priority, such as walkways, staircases, and platforms in industrial facilities.

Enhanced Safety Features

One of the primary advantages of serrated bar grates is their ability to improve safety. The serrated edges provide additional traction for personnel walking on or across these grates. This feature is particularly useful in wet or oily conditions where standard grates might become slippery. The grit-like texture reduces the likelihood of slips and falls, which are common hazards in industrial settings.

Furthermore, serrated bar grates are designed to allow for water and debris drainage. This prevents the accumulation of liquids, which can lead to dangerous conditions. In food processing environments, this drainage capability is crucial as it helps maintain hygiene by ensuring that spills are managed effectively and do not become a breeding ground for contaminants.

Structural Integrity and Load Bearing Capacity

serrated bar grate

Serrated bar grates also offer impressive structural integrity. Their design utilizes the strength of the materials they are made from, distributing weight evenly across the bars. This characteristic allows them to support heavy loads while minimizing the risk of deformation or failure. As a result, serrated bar grates are commonly used in settings that require significant weight-bearing capabilities, such as in heavy manufacturing plants, power stations, and loading docks.

The load-bearing capacity of serrated bar grates ensures that they can be relied upon in various loading scenarios, providing uninterrupted access to essential areas without compromising on safety. This contrasts with traditional flat grates, which may warp under pressure or become unstable over time.

Versatility Across Industries

The versatility of serrated bar grates means that they are applicable across various industries, including agriculture, mining, and wastewater treatment. In agriculture, they can be utilized as flooring in large animal pens or processing facilities, where durability and ease of cleaning are essential. In mining, they serve as walkways that withstand the heavy machinery commonly used in these environments, ensuring worker safety and accessibility.

Moreover, in wastewater treatment facilities, serrated bar grates assist in sedimentation tanks where they endure harsh conditions while effectively managing debris and contributing to the overall function of the system.

Conclusion

In conclusion, serrated bar grates represent a significant advancement in industrial design, combining safety, durability, and efficiency. Their unique serrated edges enhance traction, making them safer for personnel, while their robust construction allows for substantial load-bearing capabilities. This versatility makes them indispensable in various applications ranging from food processing to heavy manufacturing and construction.

As industries continue to evolve, the importance of investing in high-quality equipment and materials like serrated bar grates cannot be overstated. They not only enhance operational safety but also improve productivity and promote long-term cost savings through their durability and effectiveness. Embracing such innovations is essential for businesses looking to thrive in a competitive landscape, ultimately leading to a safer, more efficient work environment.

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024