- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

perimeter safety net

Navigating the sphere of workplace safety requires multifaceted solutions, and one tool stands out with its profound impact the perimeter safety net. For industries ranging from construction to manufacturing, these nets aren’t just protective barriers; they are critical to ensuring workforce security and minimizing liabilities.

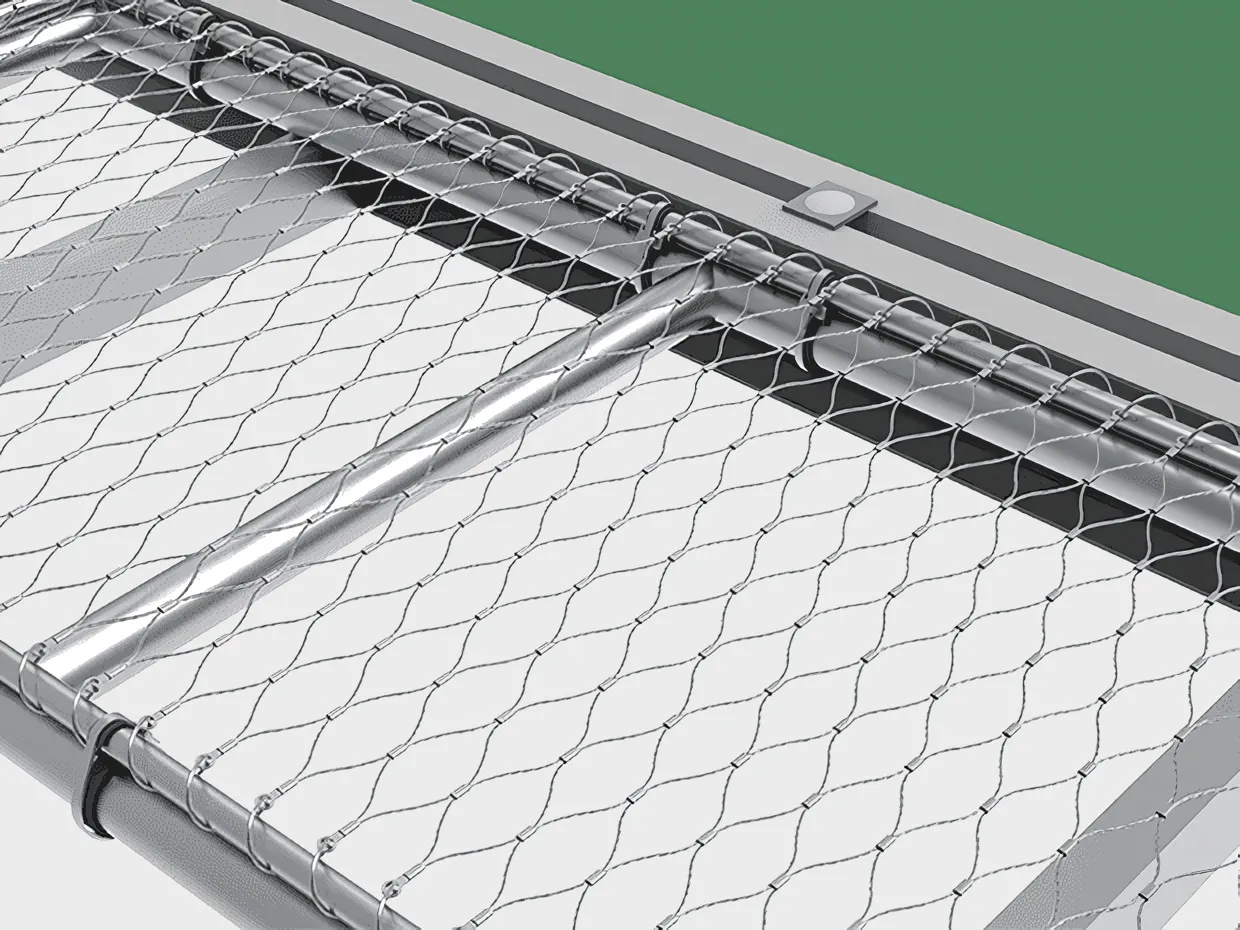

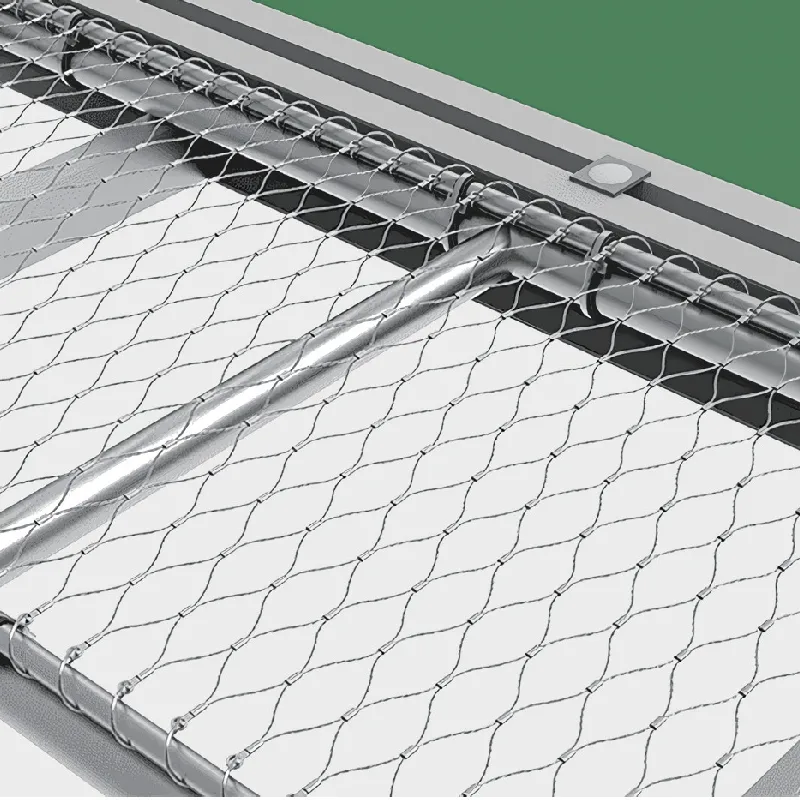

In the construction industry, often fraught with hazardous conditions and elevated workspaces, the introduction of a perimeter safety net dramatically reduces the risk of falls – a primary concern and leading cause of workplace injuries. These nets act as a physical barrier along the edges of scaffolding, roofing, and other elevated surfaces, stopping accidental slips from becoming fatal mistakes. Their design typically comprises robust and durable materials such as high-tenacity polypropylene or nylon, which are capable of absorbing the kinetic energy of a fall, thereby providing a safe landing for workers while also enabling swift rescue operations.

Expertise in deploying these nets correctly is invaluable. A well-installed perimeter safety net not only prevents accidents but also aligns with Occupational Safety and Health Administration (OSHA) standards, which mandate stringent regulations on fall protection. Industries relying on these nets require specialists trained in the intricacies of net anchoring and tensioning to optimize coverage and effectiveness. Improper installation, while seemingly negligible, could lead to catastrophic outcomes, underscoring the need for trained professionals to handle the task.

Authoritativeness is established by industry leaders who manufacture perimeter safety nets. Companies with decades of experience in textile engineering innovate continually to enhance the resilience and adaptability of these products. For example, advancements in UV resistance and weatherproofing ensure that the nets maintain their protective qualities in all environments, from the intense sun of construction sites in the Middle East to the cold, wet conditions found in parts of Northern Europe. These firms provide comprehensive training and certification programs for installing and maintaining perimeter nets, ensuring that the end-users—contractors and safety managers—can confidently rely on the equipment's ability to perform under pressure.

perimeter safety net

Trustworthiness of perimeter safety nets comes from both empirical evidence and real-world application. Case studies highlight instances where such nets have saved lives and prevented injuries, boosting morale and productivity on site by reinforcing a visible commitment to worker safety. Moreover, investing in well-designed safety nets yields financial benefits; companies mitigate legal risks, reduce insurance premiums, and avoid the costly repercussions of workplace accidents. By prioritizing safety nets, businesses signal their ethical stance on employee welfare while enhancing their reputation as responsible employers.

However, selecting the right perimeter safety net involves careful consideration of the specific needs of a project. Factors such as the height of potential falls, the typical weather conditions, and the total area requiring protection should guide this choice. This decision-making process should be informed by consultations with safety engineers and net manufacturers who can recommend the most suitable products, ensuring tailored solutions that promise optimum safety and compliance.

In conclusion, perimeter safety nets are non-negotiable in environments where falls pose a significant risk. They exemplify a commitment not only to safety standards but to a culture of care and responsibility. Through professional expertise, authoritative innovation, and demonstrated trustworthiness, these nets transform perilous tasks into manageable operations. As industries evolve and safety regulations advance, the role of perimeter safety nets will continue to be pivotal, safeguarding the most valuable asset within any organization—its people.

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024