- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

2 月 . 14, 2025 07:32

Back to list

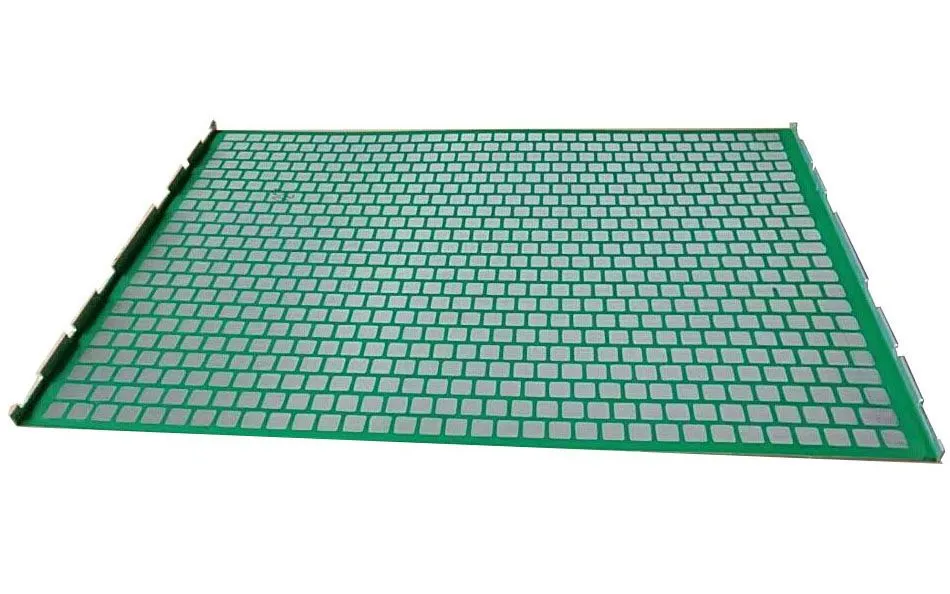

open steel floor grating

Open steel floor grating is an essential component in various commercial and industrial settings, providing both form and function. This versatile product serves a multitude of applications, from walkways and platforms to stair treads and drainage covers. In this article, we delve into the unique attributes that make open steel floor grating indispensable, sharing professional insights and addressing the core tenets of experience, expertise, authoritativeness, and trustworthiness in its use and application.

Open steel floor grating also showcases an authoritative stance in regulatory compliance. Industry standards, such as those set by the American National Standards Institute (ANSI) and the Occupational Safety and Health Administration (OSHA), dictate performance thresholds that quality grating products must meet. Adherence to these standards not only ensures the safety and reliability of the grating but also positions manufacturers as trusted leaders in the field. Companies that invest in high-quality grating reduce the likelihood of on-site accidents and potential liabilities, reinforcing their commitment to safety and excellence. Lastly, trustworthiness in using open steel floor grating is often established through verified reviews, case studies, and expert endorsements. Users sharing their experiences provide invaluable insights into the product's reliability and performance over time. Engaging with manufacturers who offer robust customer support, warranties, and consultation services further assures stakeholders of the product's value and integrity. By prioritizing transparency and customer satisfaction, these providers forge a strong connection with their clients, fostering long-term relationships built on mutual trust and respect. In conclusion, open steel floor grating represents a blend of innovation, practicality, and security, catering to the demanding needs of modern industry. Its varied applications, coupled with its adaptability and compliance with stringent safety standards, underscore its vital role in building safer and more efficient industrial environments. As the world continues to advance towards more sustainable construction and manufacturing practices, open steel floor grating remains an exemplary choice for businesses looking to enhance performance and safety while maintaining cost-effectiveness and reliability.

Open steel floor grating also showcases an authoritative stance in regulatory compliance. Industry standards, such as those set by the American National Standards Institute (ANSI) and the Occupational Safety and Health Administration (OSHA), dictate performance thresholds that quality grating products must meet. Adherence to these standards not only ensures the safety and reliability of the grating but also positions manufacturers as trusted leaders in the field. Companies that invest in high-quality grating reduce the likelihood of on-site accidents and potential liabilities, reinforcing their commitment to safety and excellence. Lastly, trustworthiness in using open steel floor grating is often established through verified reviews, case studies, and expert endorsements. Users sharing their experiences provide invaluable insights into the product's reliability and performance over time. Engaging with manufacturers who offer robust customer support, warranties, and consultation services further assures stakeholders of the product's value and integrity. By prioritizing transparency and customer satisfaction, these providers forge a strong connection with their clients, fostering long-term relationships built on mutual trust and respect. In conclusion, open steel floor grating represents a blend of innovation, practicality, and security, catering to the demanding needs of modern industry. Its varied applications, coupled with its adaptability and compliance with stringent safety standards, underscore its vital role in building safer and more efficient industrial environments. As the world continues to advance towards more sustainable construction and manufacturing practices, open steel floor grating remains an exemplary choice for businesses looking to enhance performance and safety while maintaining cost-effectiveness and reliability.

Share

Prev:

Next:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024