- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

2 月 . 19, 2025 08:53

Back to list

Offshore Pipeline Counterweight Welded Wire Mesh

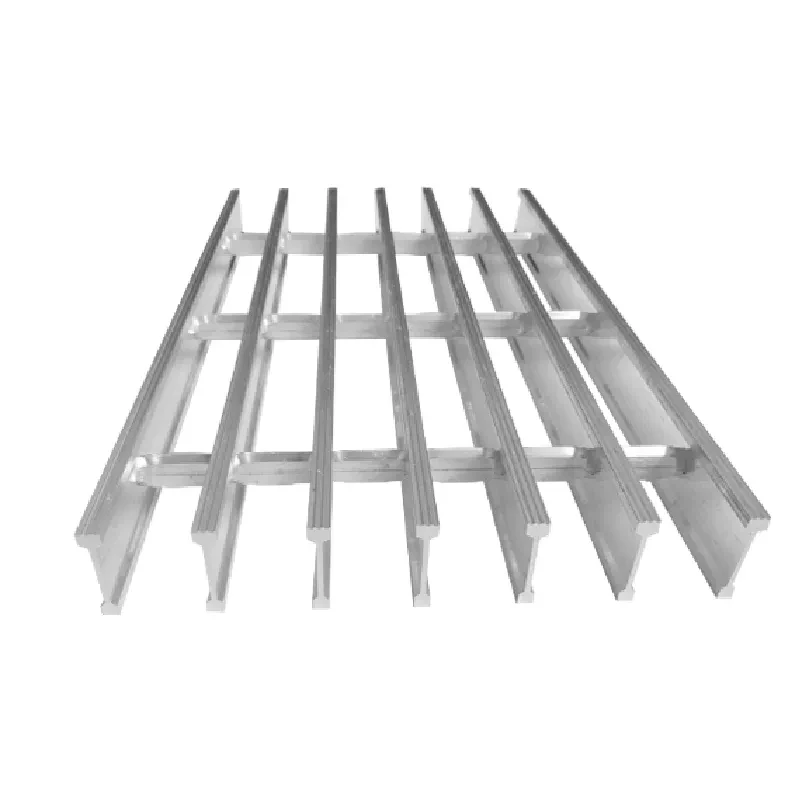

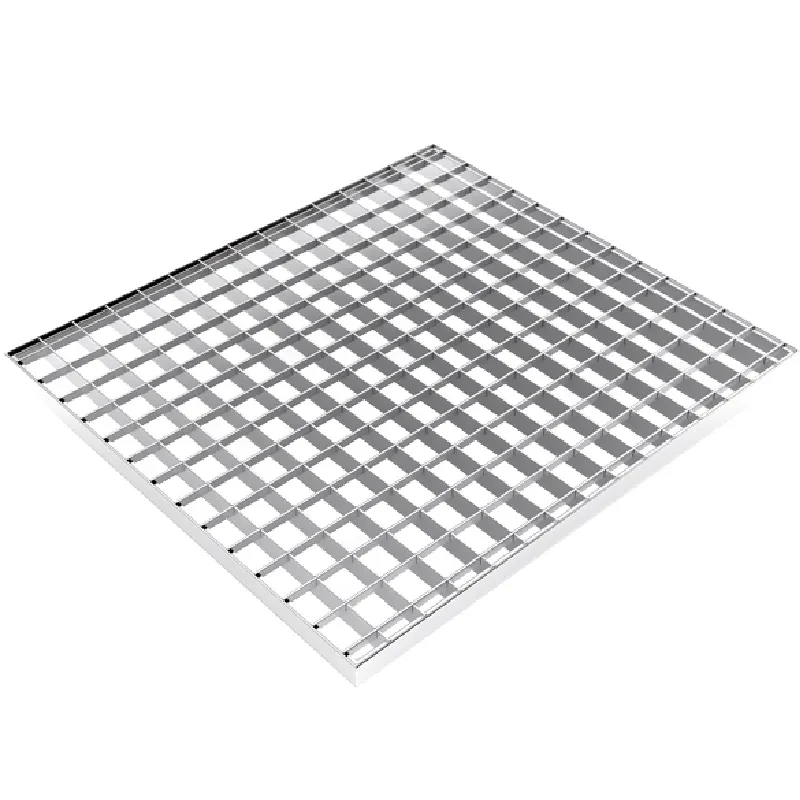

Open grate flooring is transforming industries with its versatile applications and unparalleled performance. This flooring solution, characterized by its grid-like design, is being increasingly recognized for its utility across diverse sectors. Marrying form and function, open grate flooring enhances safety, efficiency, and durability in demanding environments.

Besides functional advantages, open grate flooring is backed by extensive research and certifications, ensuring its trustworthiness. Many manufacturers adhere to ISO standards, and floors undergo rigorous testing to validate load capacities, slip resistance, and environmental impact. This commitment to quality assurance not only underscores the flooring's reliability but also provides peace of mind to businesses prioritizing employee safety and regulatory compliance. The adoption of open grate flooring extends beyond mere practicality; it underscores a commitment to sustainable practices. Many grating solutions incorporate recycled materials, aligning with eco-friendly initiatives. This sustainability aspect resonates with companies aiming to reduce their carbon footprint while maintaining operational excellence. Expert installers and consultants offer invaluable insights during the selection and installation phases, enhancing the flooring's performance throughout its lifecycle. Professional guidance ensures optimal material choice, precise installation, and adherence to safety protocols, further solidifying open grate flooring's reputation as a trusted flooring solution. Embracing open grate flooring is a strategic decision that prioritizes safety, expertise, and sustainability. Its proven track record, combined with cutting-edge features, makes it an indispensable choice for industries seeking to elevate their infrastructural integrity. As more sectors realize its potential, open grate flooring is set to become a cornerstone of industrial flooring solutions, representing an innovative leap towards safer and more efficient operational environments.

Besides functional advantages, open grate flooring is backed by extensive research and certifications, ensuring its trustworthiness. Many manufacturers adhere to ISO standards, and floors undergo rigorous testing to validate load capacities, slip resistance, and environmental impact. This commitment to quality assurance not only underscores the flooring's reliability but also provides peace of mind to businesses prioritizing employee safety and regulatory compliance. The adoption of open grate flooring extends beyond mere practicality; it underscores a commitment to sustainable practices. Many grating solutions incorporate recycled materials, aligning with eco-friendly initiatives. This sustainability aspect resonates with companies aiming to reduce their carbon footprint while maintaining operational excellence. Expert installers and consultants offer invaluable insights during the selection and installation phases, enhancing the flooring's performance throughout its lifecycle. Professional guidance ensures optimal material choice, precise installation, and adherence to safety protocols, further solidifying open grate flooring's reputation as a trusted flooring solution. Embracing open grate flooring is a strategic decision that prioritizes safety, expertise, and sustainability. Its proven track record, combined with cutting-edge features, makes it an indispensable choice for industries seeking to elevate their infrastructural integrity. As more sectors realize its potential, open grate flooring is set to become a cornerstone of industrial flooring solutions, representing an innovative leap towards safer and more efficient operational environments.

Share

Prev:

Next:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024