- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

1 月 . 22, 2025 03:43

Back to list

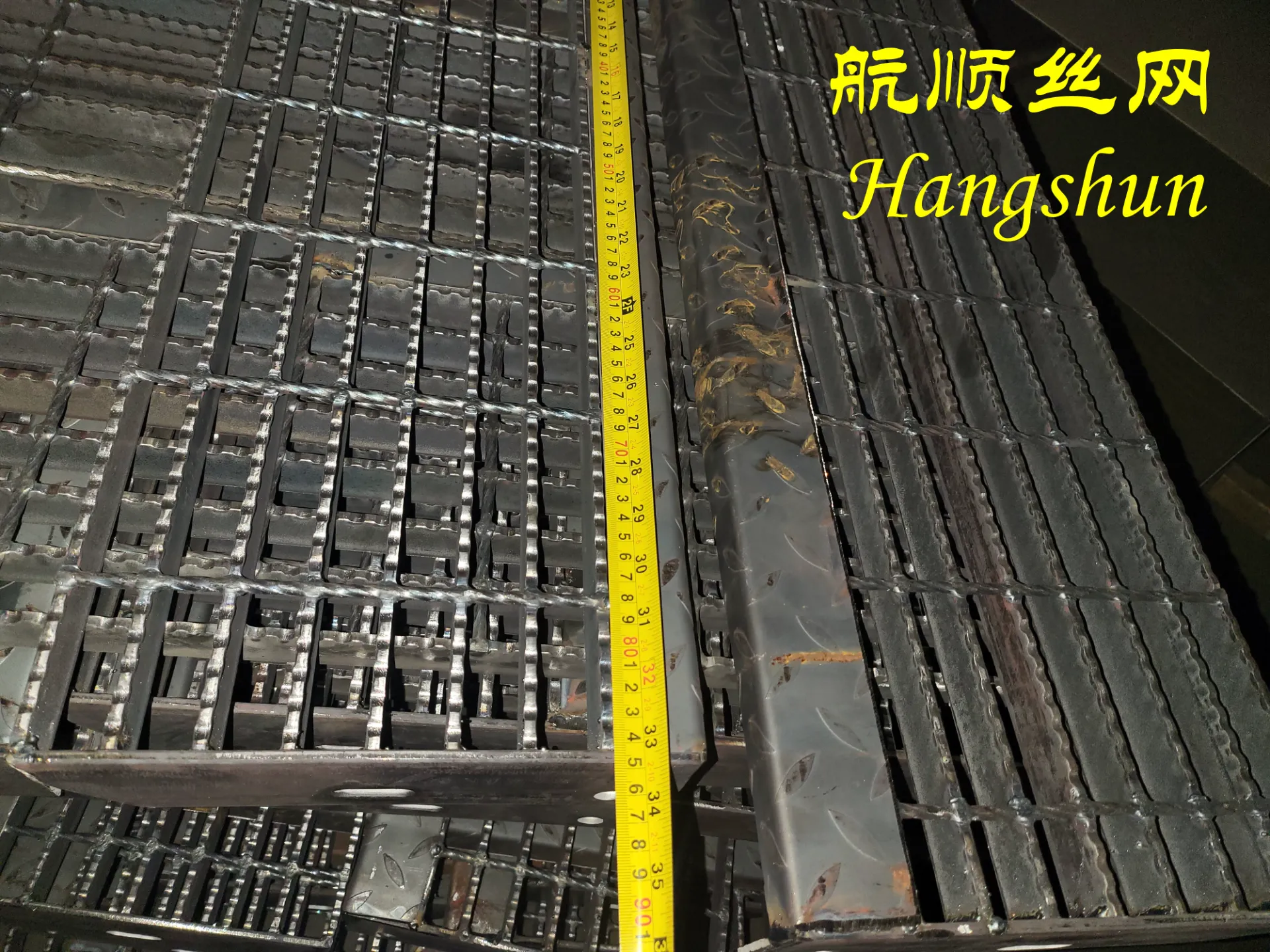

heavy-duty welded bar grating

Open bar grating is an essential component in a variety of industrial and commercial applications, offering a myriad of benefits due to its strength, durability, and versatility. For those exploring the different options available in open bar grating, it’s important to consider factors that align with the four critical SEO principles Experience, Expertise, Authoritativeness, and Trustworthiness.

Advancements in manufacturing technology have enhanced the design and functionality of open bar gratings. Modern developments include load bars and cross bars welded at precise intervals to enhance structural integrity and ease of installation. These advancements translate into cost savings over time due to reduced maintenance and increased safety, attributes that my past projects have benefitted from significantly. When selecting open bar grating, consider the application environment. Are there specific conditions that require particular material properties? For example, marine environments necessitate the use of materials that resist corrosion and can withstand saltwater exposure. For environments where hygiene is critical, like food processing plants, stainless steel gratings with hygienic surface finishes would be appropriate. My past experiences affirm that such tailored choices can make a substantial difference in the performance and maintenance costs of an installation. Moreover, the aesthetic appeal of open bar grating can also influence choice, especially in commercial settings where design and appearance are just as important as functionality. Customized grating with powder-coated finishes or specific patterns can enhance the overall look while maintaining the necessary safety standards. Overall, selecting the right open bar grating involves a blend of practical experience, industry knowledge, a reliance on authoritative standards, and trust in proven manufacturers. By understanding and considering these aspects, you can make informed decisions that not only meet but exceed operational requirements, ensuring a solution that delivers performance, safety, and value. With the complexities of modern applications, having a seasoned perspective in choosing open bar gratings can be the defining factor between a functional space and an exemplary safe and efficient environment.

Advancements in manufacturing technology have enhanced the design and functionality of open bar gratings. Modern developments include load bars and cross bars welded at precise intervals to enhance structural integrity and ease of installation. These advancements translate into cost savings over time due to reduced maintenance and increased safety, attributes that my past projects have benefitted from significantly. When selecting open bar grating, consider the application environment. Are there specific conditions that require particular material properties? For example, marine environments necessitate the use of materials that resist corrosion and can withstand saltwater exposure. For environments where hygiene is critical, like food processing plants, stainless steel gratings with hygienic surface finishes would be appropriate. My past experiences affirm that such tailored choices can make a substantial difference in the performance and maintenance costs of an installation. Moreover, the aesthetic appeal of open bar grating can also influence choice, especially in commercial settings where design and appearance are just as important as functionality. Customized grating with powder-coated finishes or specific patterns can enhance the overall look while maintaining the necessary safety standards. Overall, selecting the right open bar grating involves a blend of practical experience, industry knowledge, a reliance on authoritative standards, and trust in proven manufacturers. By understanding and considering these aspects, you can make informed decisions that not only meet but exceed operational requirements, ensuring a solution that delivers performance, safety, and value. With the complexities of modern applications, having a seasoned perspective in choosing open bar gratings can be the defining factor between a functional space and an exemplary safe and efficient environment.

Share

Prev:

Next:

Latest news

-

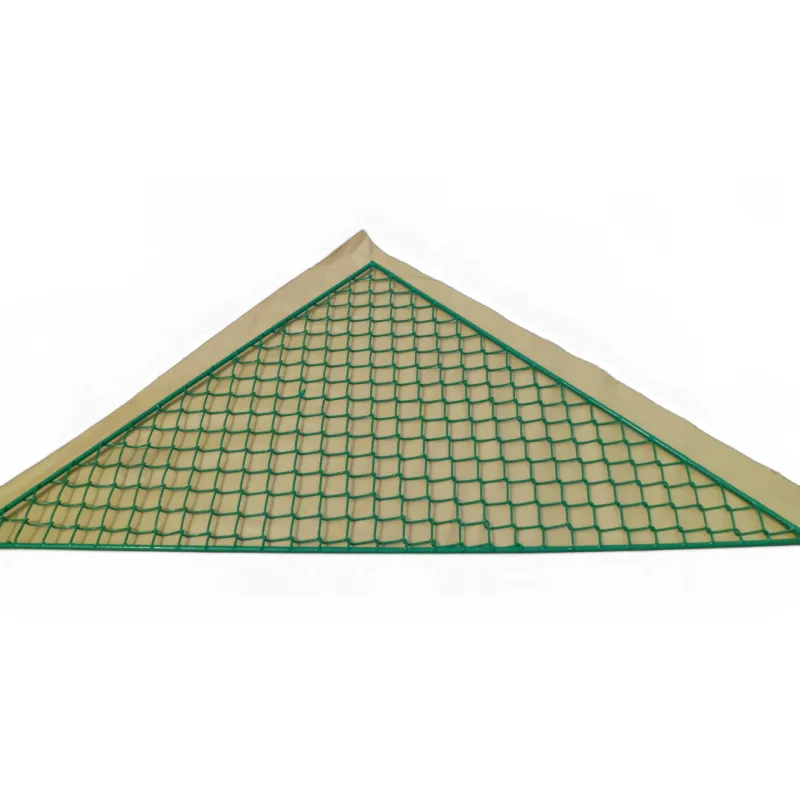

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024