- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Effective Techniques for Applying Concrete Weight Coating on Pipelines

Concrete Weight Coating for Pipelines An Essential Component in Pipeline Installation

In the world of pipeline installation, particularly for subsea and onshore applications, one critical component often overlooked is concrete weight coating. This specialized protective layer plays a pivotal role in ensuring the stability, safety, and longevity of pipelines transporting various fluids, including oil and gas.

Concrete Weight Coating for Pipelines An Essential Component in Pipeline Installation

The process of applying concrete weight coating typically begins with surface preparation. The pipeline must be thoroughly cleaned to remove any contaminants, such as grease, dirt, or rust, which could interfere with the adhesion of the concrete. Once prepared, the pipelines are passed through a concrete coating facility, where the concrete is applied in layers. This can be customized in thickness depending on the specific requirements of the project and the environment in which the pipeline will be placed.

oncrete weight coating pipeline

Another significant benefit of concrete weight coating is its protective nature. The concrete layer serves as a barrier against external damage, such as abrasions or impacts that may occur during installation or due to environmental factors. It also provides protection against corrosion, especially in subsea applications where pipelines are exposed to saltwater and other corrosive substances. Coupled with other protective measures, like internal coatings, concrete weight coating can significantly extend the lifespan of pipelines.

Environmental considerations play an essential role in the use of concrete weight coatings. The production and application of concrete must comply with various environmental regulations to minimize the ecological footprint of the pipeline installation process. Furthermore, as industries worldwide strive for sustainable practices, advancements in materials science are leading to the development of more eco-friendly concrete formulations. These innovations include the use of recycled materials and reduced carbon emissions during production, contributing positively to environmental conservation.

While the technicalities of concrete weight coating may seem intricate, its importance cannot be overstated. Engineers and project managers must consider various factors, including the weight of the coating, the pipeline's purpose, and the environmental conditions present. Properly executed concrete weight coating ensures the integrity of the pipeline system, safeguarding against potential failures that could lead to costly repairs and environmental disasters.

In conclusion, concrete weight coating is a fundamental aspect of pipeline construction and maintenance. By providing crucial stability and protection, it helps ensure that pipelines can perform their intended functions while minimizing risks associated with transportation and environmental impact. As the energy sector continues to evolve, the importance of such protective measures will only grow, proving the necessity of thoughtful engineering and sustainable practices in pipeline design and execution.

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

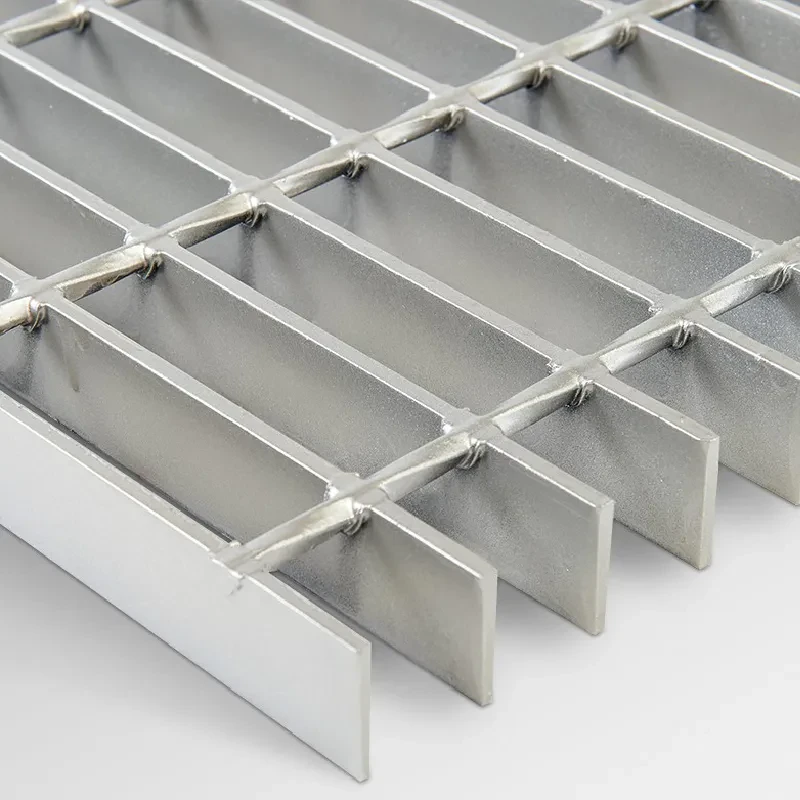

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024