- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

2 月 . 13, 2025 11:47

Back to list

concrete weight coating

The efficiency and effectiveness of a pipeline network can significantly influence the success of oil, gas, and water transportation projects. Among the many factors that contribute to the robustness and longevity of pipeline infrastructure, one critical element often overlooked is concrete weight coating. This specialized protective layer not only enhances the durability and stability of pipelines under various environmental conditions but also plays a crucial role in maintaining operational efficiency.

Another aspect contributing to the authoritativeness of concrete weight coating is its alignment with stringent industry standards and regulations. It satisfies both national and international guidelines concerning environmental protection and safety, ensuring that pipeline operations do not harm ecological systems. By utilizing environmentally friendly concrete compositions, this method reduces the ecological footprint of pipeline constructions, aligning with global sustainability goals. Investing in concrete weight coating also offers a competitive edge in the marketplace. Beyond its protective qualities, it provides an additional seal against external threats such as fishing activities and underwater seismic movements, a feature particularly beneficial for pipelines located in high-traffic or geologically unstable regions. This robust protection framework not only contributes to operational uptime but also reduces insurance costs related to accidents or environmental damages. Lastly, the durability and low-maintenance nature of concrete weight coated pipelines contribute to long-term cost savings. With extended longevity and fewer repair requirements, companies can allocate resources more efficiently, focusing on expansion and technological enhancements instead of frequent maintenance. This financial prudence ultimately enhances the return on investment, making concrete weight coating a strategic choice in pipeline construction and management. In conclusion, concrete weight coating stands as a testament to innovative engineering solutions meeting practical operational needs. Its application reflects an intricate balance of scientific precision and environmental consideration, ensuring pipelines remain safe, efficient, and environmentally responsible. As industries continue to pursue more sustainable and resilient infrastructure, the role of concrete weight coating will undoubtedly remain pivotal in shaping the future of pipeline technology.

Another aspect contributing to the authoritativeness of concrete weight coating is its alignment with stringent industry standards and regulations. It satisfies both national and international guidelines concerning environmental protection and safety, ensuring that pipeline operations do not harm ecological systems. By utilizing environmentally friendly concrete compositions, this method reduces the ecological footprint of pipeline constructions, aligning with global sustainability goals. Investing in concrete weight coating also offers a competitive edge in the marketplace. Beyond its protective qualities, it provides an additional seal against external threats such as fishing activities and underwater seismic movements, a feature particularly beneficial for pipelines located in high-traffic or geologically unstable regions. This robust protection framework not only contributes to operational uptime but also reduces insurance costs related to accidents or environmental damages. Lastly, the durability and low-maintenance nature of concrete weight coated pipelines contribute to long-term cost savings. With extended longevity and fewer repair requirements, companies can allocate resources more efficiently, focusing on expansion and technological enhancements instead of frequent maintenance. This financial prudence ultimately enhances the return on investment, making concrete weight coating a strategic choice in pipeline construction and management. In conclusion, concrete weight coating stands as a testament to innovative engineering solutions meeting practical operational needs. Its application reflects an intricate balance of scientific precision and environmental consideration, ensuring pipelines remain safe, efficient, and environmentally responsible. As industries continue to pursue more sustainable and resilient infrastructure, the role of concrete weight coating will undoubtedly remain pivotal in shaping the future of pipeline technology.

Share

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

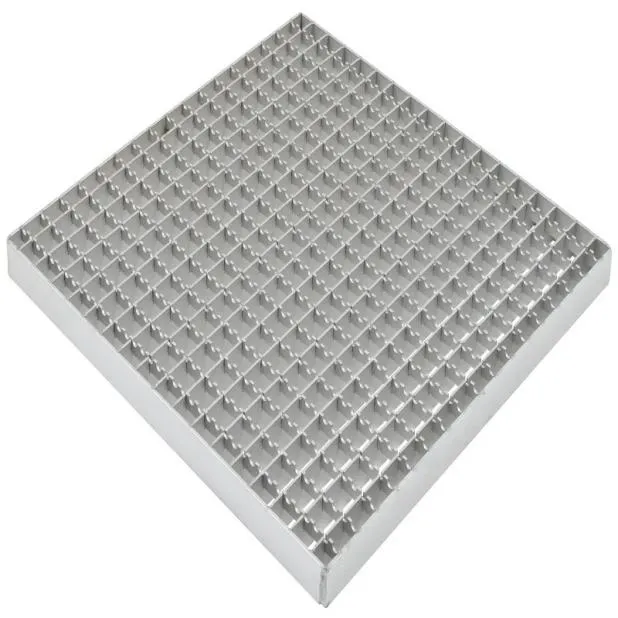

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

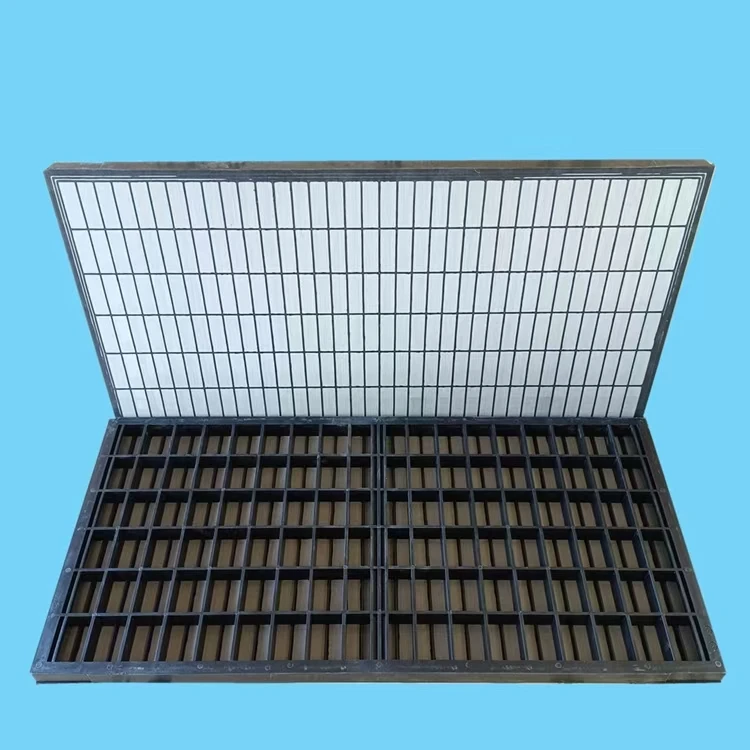

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024