- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

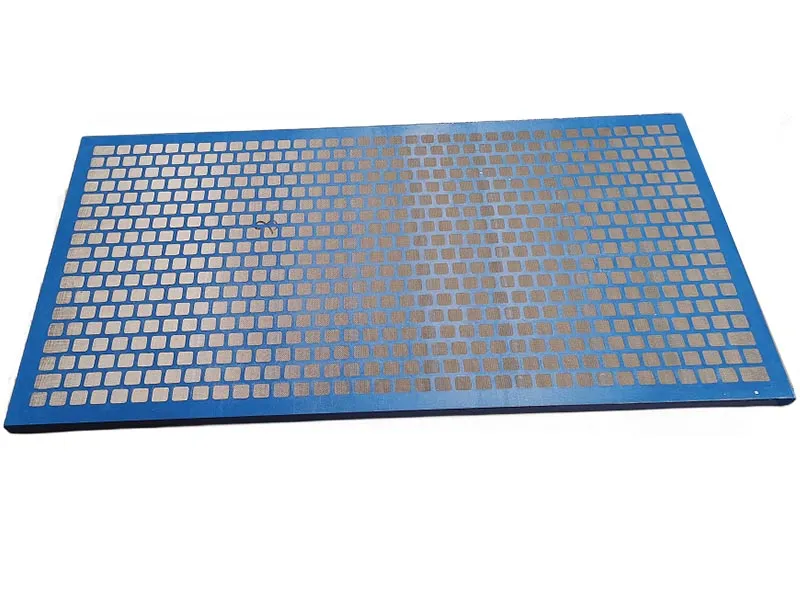

Mild Steel Grating Applications and Benefits in Construction and Industrial Settings

Mild steel grating is a versatile and widely used component in various industries due to its strength, durability, and cost-effectiveness. Often manufactured from mild steel, which is known for its excellent weldability and machinability, this type of grating serves numerous applications, particularly in industrial settings.

One of the primary advantages of mild steel grating is its ability to withstand heavy loads. This makes it ideal for use in environments where heavy machinery or vehicles are present, such as factories, warehouses, and construction sites. The grating's structure allows for effective load distribution, providing a stable and safe surface for both personnel and equipment. Additionally, its open design promotes drainage, reducing the risk of water accumulation and minimizing hazards related to slipping or standing water.

Mild steel grating is available in various types and configurations, including welded, riveted, and pressed styles. Each of these designs offers unique benefits, tailored to specific needs. For instance, welded grating provides a more robust and long-lasting solution, making it suitable for applications that require higher load-bearing capabilities. On the other hand, riveted grating is often used in situations where flexibility and ease of installation are essential.

The surface treatment of mild steel grating is another critical aspect that enhances its performance. Typically, it is galvanized to provide corrosion resistance, greatly extending its lifespan, especially in outdoor or humid environments. This protective layer not only enhances durability but also reduces maintenance costs over time, making mild steel grating a practical choice for budget-conscious projects.

mild steel grating

Furthermore, mild steel grating can be customized to fit specific dimensions and design requirements. Whether it’s for an industrial platform, stair treads, or walkways, manufacturers can provide tailored solutions that meet the exact specifications of a project. This level of customization ensures that the grating not only serves its intended purpose effectively but also integrates seamlessly with existing structures.

In addition to its practical applications, mild steel grating can also contribute to the aesthetic design of a facility. With options available in various finishes and styles, it can enhance the overall appearance of industrial settings while maintaining functionality.

In conclusion, mild steel grating is an essential component in many industries, known for its strength, versatility, and cost-effectiveness. Its ability to bear heavy loads, combined with corrosion resistance and customization options, makes it a preferred choice for a wide range of applications. Whether for industrial use or architectural projects, mild steel grating continues to be a reliable solution for creating safe and efficient environments.

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024