- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Understanding the Properties and Applications of Mild Steel Grating in Industrial Settings

Understanding Mild Steel Grating A Comprehensive Overview

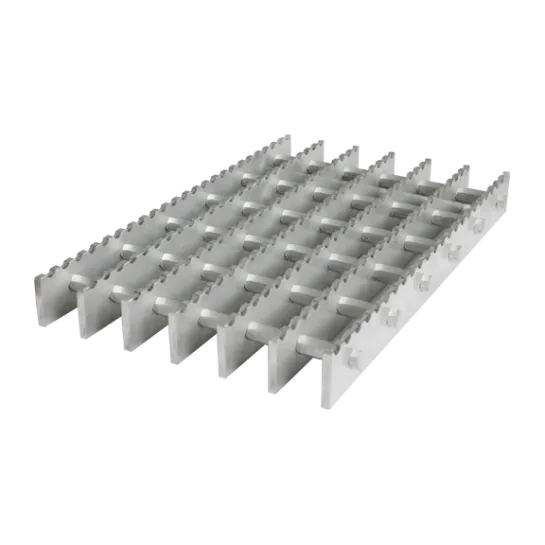

Mild steel grating is a versatile and widely used material in various industrial and architectural applications. It is made from mild steel, an alloy of iron that contains a low percentage of carbon, giving it excellent durability, flexibility, and weldability. In this article, we will explore the characteristics, benefits, applications, and maintenance of mild steel grating, providing a holistic understanding of its importance in modern engineering and construction.

Characteristics of Mild Steel Grating

Mild steel grating is known for its numerous advantageous properties. Firstly, it has a relatively lightweight structure compared to other metal gratings, making it easier to handle and install. The open design of the grating allows for good drainage and ventilation, which is crucial in applications like walkways, platforms, and drainage covers.

Another key characteristic is its load-bearing capacity. Mild steel grating is designed to withstand heavy loads, making it ideal for industrial environments where heavy machinery and equipment are in use. Additionally, mild steel is recyclable, contributing to sustainable practices in construction and manufacturing.

The surface of mild steel grating can be treated with various coatings to enhance its resistance to corrosion and wear. Common treatments include hot-dip galvanizing, painting, or powder coating, which extend the material's lifespan and maintain its aesthetic appeal.

Benefits of Mild Steel Grating

One of the most significant benefits of mild steel grating is its cost-effectiveness. It offers a balance between performance, durability, and price, making it an economical choice for many projects. Furthermore, its ease of fabrication allows for custom designs, catering to specific requirements without substantial additional costs.

The adaptability of mild steel grating is another advantage. It can be tailored in terms of size, shape, and spacing to meet varied application needs. This customization makes it suitable for a range of environments, from commercial buildings to warehouses and manufacturing facilities.

Safety is paramount in industrial applications, and mild steel grating contributes to safety through its slip-resistant surface. The open design reduces the likelihood of water pooling, minimizing slip hazards. Moreover, its strength prevents deformation under heavy loads, offering stability and safety in walkways, ramps, and platforms.

mild steel grating

Applications of Mild Steel Grating

Mild steel grating finds applications in numerous sectors, including construction, manufacturing, transportation, and municipal infrastructure. Some common uses include

1. Walkways and Platforms Mild steel grating is often used for constructing walkways in warehouses, factories, and commercial buildings due to its strength and slip-resistant properties. 2. Stair Treads and Ramps Gratings help improve safety on stairs and ramps, ensuring that users have a secure footing in environments prone to spills or water accumulation. 3. Drainage Covers The open design of mild steel grating allows for effective drainage, making it an excellent choice for drainage covers in streets, parking lots, and industrial areas. 4. CROSSOVER and Bridge Decking Mild steel grating can be used for crossover platforms and bridge decking, providing a strong and lightweight solution that can handle heavy traffic.

5. Industrial Flooring In manufacturing plants, mild steel grating is utilized as flooring in areas that require high durability and ease of maintenance.

Maintenance of Mild Steel Grating

To maximize the lifespan of mild steel grating, proper maintenance is essential. Regular inspections should be conducted to identify signs of wear, rust, or corrosion. If any damage is found, timely repairs should be made to prevent further deterioration.

Additionally, periodic cleaning is necessary to remove debris and contaminants that may accumulate on the surface. Depending on the specific coating applied, the frequency of maintenance will vary; galvanized surfaces may require less frequent upkeep compared to uncoated grating.

In environments where exposure to harsh chemicals or extreme weather is common, regular re-coating may be necessary to maintain corrosion resistance.

Conclusion

Mild steel grating is an invaluable material in various engineering and construction applications, offering a blend of strength, flexibility, and cost effectiveness. Its wide range of uses, combined with the relatively low maintenance requirements, make it a preferred choice for many professionals in the field. By understanding the characteristics, benefits, applications, and maintenance of mild steel grating, companies and individual contractors can harness its potential to create safe, efficient, and durable solutions in their projects.

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024