- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

1 月 . 22, 2025 02:57

Back to list

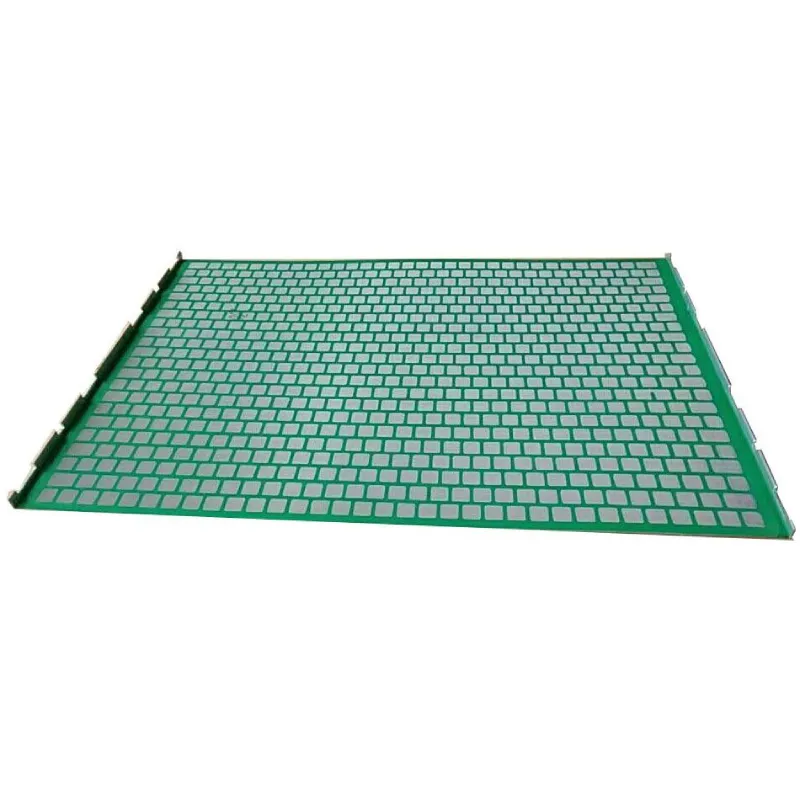

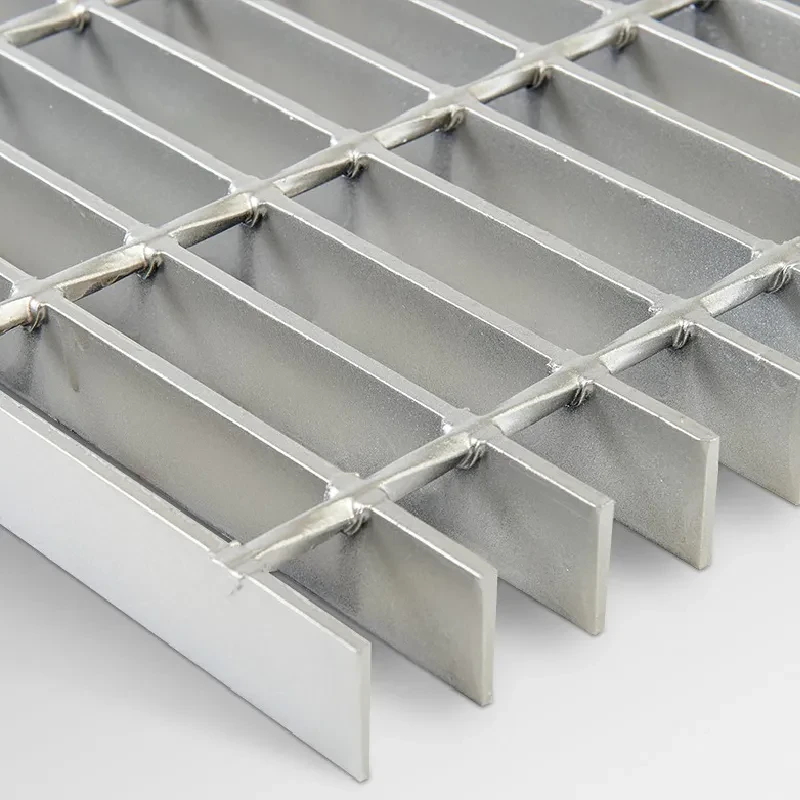

metal grating for sale

In the ever-evolving landscape of industrial materials, metal mesh grating stands out as an essential component across various industries. Its versatility and robust characteristics make it a popular choice for architects, engineers, and construction professionals. The following insights delve into the vast array of benefits and applications of metal mesh grating, highlighting its unmatched expertise, authoritativeness, and trustworthiness in the field.

Sustainability is another key aspect of metal mesh grating that enhances its credibility and appeal. Unlike traditional materials that may degrade quickly or are difficult to recycle, metal mesh grating is recyclable, contributing to circular economy practices. Its lifecycle further benefits from minimal maintenance requirements, reducing the need for frequent replacements and associated environmental impacts. In terms of expertise, metal mesh grating offers unparalleled customizability to meet specific project requirements. Manufacturers provide a wide range of options in terms of material types, sizes, and finishes, ensuring that the grating can be tailored to particular applications, whether lightweight aluminum for temporary structures or heavy-duty steel for permanent installations. This adaptability highlights the proficient use of metal grating across numerous sectors. To harness the full potential of metal mesh grating, professionals should involve reputable suppliers and manufacturers early in the design process. Their insights and expertise ensure optimal material selection and system design, aligning with both aesthetic and functional aspirations. This collaboration is crucial for achieving the desired performance outcomes while adhering to budget constraints. In conclusion, the utilization of metal mesh grating showcases a remarkable blend of experience, expertise, authoritativeness, and trustworthiness. Its wide range of applications—from industrial to architectural—demonstrates its versatility and indispensability. As industries continue to evolve, the demand for materials that offer both aesthetic and functional benefits is likely to grow, further cementing metal mesh grating as a staple in modern design and construction.

Sustainability is another key aspect of metal mesh grating that enhances its credibility and appeal. Unlike traditional materials that may degrade quickly or are difficult to recycle, metal mesh grating is recyclable, contributing to circular economy practices. Its lifecycle further benefits from minimal maintenance requirements, reducing the need for frequent replacements and associated environmental impacts. In terms of expertise, metal mesh grating offers unparalleled customizability to meet specific project requirements. Manufacturers provide a wide range of options in terms of material types, sizes, and finishes, ensuring that the grating can be tailored to particular applications, whether lightweight aluminum for temporary structures or heavy-duty steel for permanent installations. This adaptability highlights the proficient use of metal grating across numerous sectors. To harness the full potential of metal mesh grating, professionals should involve reputable suppliers and manufacturers early in the design process. Their insights and expertise ensure optimal material selection and system design, aligning with both aesthetic and functional aspirations. This collaboration is crucial for achieving the desired performance outcomes while adhering to budget constraints. In conclusion, the utilization of metal mesh grating showcases a remarkable blend of experience, expertise, authoritativeness, and trustworthiness. Its wide range of applications—from industrial to architectural—demonstrates its versatility and indispensability. As industries continue to evolve, the demand for materials that offer both aesthetic and functional benefits is likely to grow, further cementing metal mesh grating as a staple in modern design and construction.

Share

Prev:

Next:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024