- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Calculating the Weight of Metal Grating for Structural Applications and Design Considerations

Understanding Metal Grating Weight A Comprehensive Overview

Metal grating is an essential component in various industrial and construction applications due to its durability, strength, and load-bearing capabilities. However, one critical aspect that often comes into play when selecting metal grating for specific uses is its weight. Understanding the weight of metal grating is crucial not just for transportation and installation, but also for ensuring that it meets the load requirements of its intended application.

What is Metal Grating?

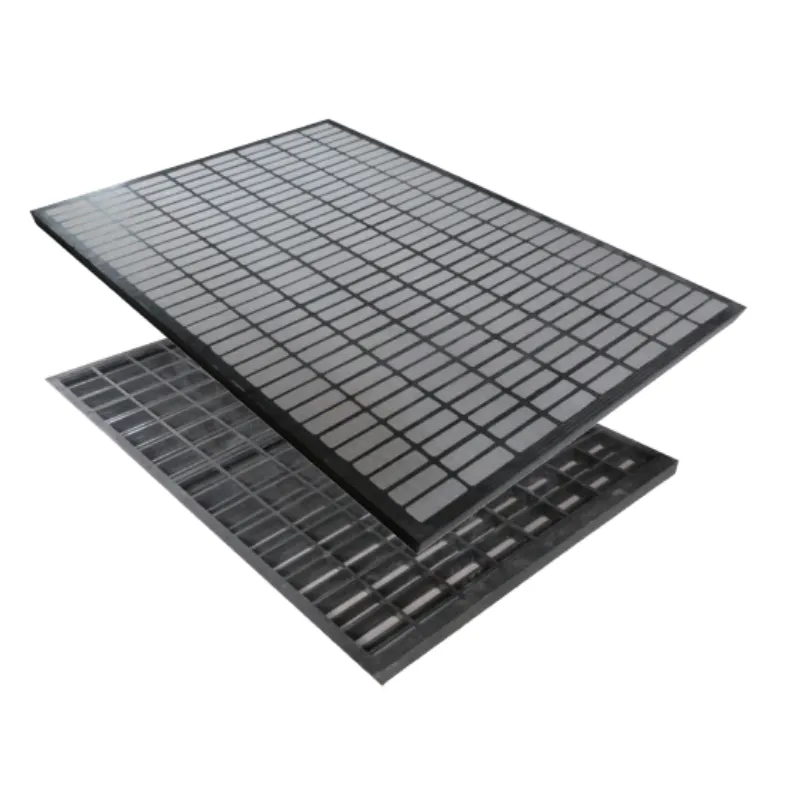

Metal grating is a structure made from metal bars or plates, which are arranged in a grid-like pattern to form a surface that allows for the passage of light, air, and water. Common materials used to produce metal grating include steel, aluminum, and stainless steel. It finds applications in various settings, from walkways and platforms to drainage covers and industrial flooring.

Factors Influencing the Weight of Metal Grating

Several factors influence the weight of metal grating. These include

1. Material Type The specific metal used significantly affects the grating's weight. For instance, aluminum grating is lighter than steel grating, making it suitable for applications where weight is a concern, such as in aerial walkways or lightweight structures. Steel grating, while heavier, offers superior strength and durability, making it ideal for heavy-load applications in industrial environments.

2. Thickness of Bars The thickness of the individual bars that make up the grating also plays a critical role in determining overall weight. Thicker bars provide greater strength and load capacity but will increase the grating's overall weight.

3. Bar Spacing The distance between the bars can also influence weight. Closer spacing typically means more material is used, thus increasing weight. Collaboratively, spacing must balance load capacities and weight considerations.

4. Grating Type Different types of metal grating (such as welded, swaged, or decorative) can have varying weights. For example, welded grating tends to be heavier due to the additional material used during the manufacturing process compared to swaged grating.

metal grating weight

Calculating Metal Grating Weight

Calculating the weight of metal grating is relatively straightforward. The general formula involves determining the weight per square foot and then multiplying by the total square footage of the grating required. Standard manufacturers often provide charts that specify the weight of various grating types based on their dimensions, materials, and designs.

Importance of Weight Considerations

Considering the weight of metal grating is vital for several reasons

- Structural Integrity Overloading a structure with grating that is too heavy can lead to structural failures, which can be costly and dangerous. Ensuring the right weight capacity is fundamental for safety.

- Transport and Handling Understanding the weight is essential for logistics, influencing transportation methods, handling procedures, and installation techniques. Heavy grating may require specialized equipment to move and install.

- Cost Efficiency Often, the weight of the material can affect shipping costs and installation expenses. Lighter materials may incur lower transportation costs and be more manageable during installation.

Conclusion

Metal grating weight is an integral factor in the selection and application of grating in various industries. By considering factors such as material type, bar thickness, spacing, and grating type, one can make informed choices that not only fulfill functional requirements but also ensure safety and cost-effectiveness. Whether for industrial applications or commercial use, understanding metal grating weight is essential for achieving optimal results in design and construction projects.

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024