- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Calculating the Weight of Metal Grating for Construction and Industrial Applications

Understanding the Weight of Metal Gratings

Metal gratings are essential components in various industrial and construction applications, serving purposes ranging from walkways and platforms to drainage covers and safety barriers. One of the pivotal factors to consider when selecting a metal grating for a project is its weight. Understanding the relationship between metal grating weight, material type, and design can greatly influence both the performance and safety of the installation.

The Basics of Metal Grating

Metal grating is typically made from materials such as steel, aluminum, or stainless steel. Each of these materials has distinct properties that affect the weight of the grating. Steel gratings are known for their strength and load-bearing capabilities, making them an excellent choice for heavy industrial applications. However, they are generally heavier than aluminum or stainless steel. Aluminum gratings, on the other hand, are lighter, making them ideal for applications where weight is a critical consideration, such as in portable structures or lightweight platforms. Stainless steel combines the benefits of strength and corrosion resistance but is often heavier than aluminum.

Factors Influencing Weight

The weight of metal grating is influenced primarily by the following factors

1. Material Density The density of the material used directly impacts the weight. For example, steel has a density of approximately 7.85 g/cm³, aluminum is about 2.7 g/cm³, and stainless steel ranges around 8.0 g/cm³. This difference in density means that, for the same volume, steel gratings will weigh significantly more than aluminum gratings.

2. Grating Design The design of the grating—such as the spacing between bars and the thickness of the individual bars—also plays a crucial role in determining weight. Common designs include welded, swaged, and pressure-locked configurations. Thicker bars will increase the overall weight, whereas wider spacing can reduce it.

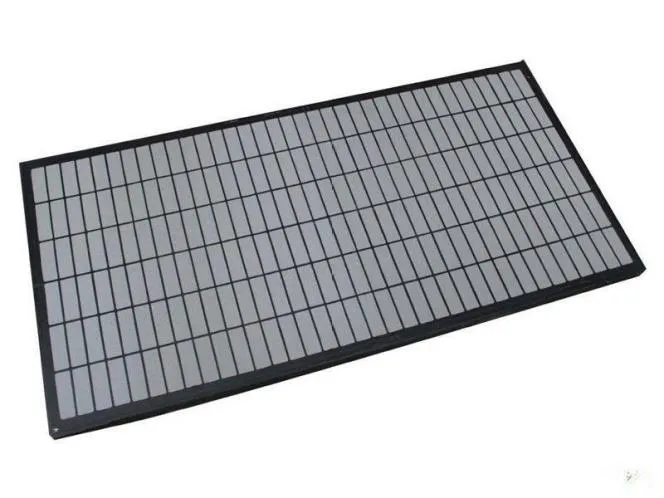

metal grating weight

3. Size and Dimensions Naturally, larger gratings will weigh more than smaller ones. The length, width, and overall surface area of the grating must be considered when calculating total weight.

4. Load Requirements Different applications necessitate different load capacities. Gratings designed for heavy-duty industrial use will typically be constructed from thicker materials and thus weigh more than those designed for lighter applications, such as in residential settings.

Practical Implications

When planning a project, the weight of metal grating has several practical implications. For structural designs, knowing the weight helps in calculating loading capacities for floors and supports. It is also crucial for transportation considerations; lighter gratings can lead to reduced shipping costs and easier handling on site.

In applications involving elevated walkways or platforms, the increased weight of heavier metal gratings must be reconciled with structural support capabilities. Engineers must assess whether existing support structures can handle higher weights without compromising safety.

Conclusion

The weight of metal grating is more than just a number; it is a critical aspect that affects design, functionality, and safety. By understanding how material type, design, and dimensions interact to determine weight, professionals in construction and manufacturing can make informed choices, ensuring their projects remain efficient and safe. As industries continue to evolve, the demand for lightweight yet durable materials will drive innovations in grating design and material engineering, paving the way for safer and more efficient applications in the future.

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024