- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

metal grating weight

Understanding Metal Grating Weight Key Factors and Considerations

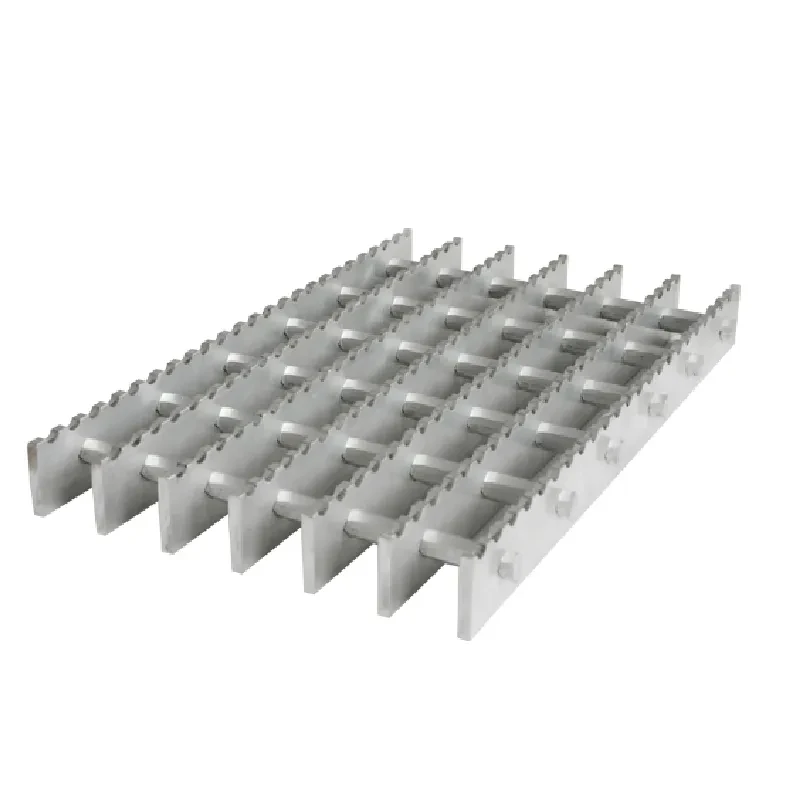

Metal grating is a widely used material in various industries due to its strength, durability, and versatility. It serves critical functions in construction, manufacturing, and infrastructure projects, acting as walkways, platforms, and even as part of drainage systems. One important aspect of metal grating that needs careful consideration is its weight, which can influence both the design and application of these structures.

Understanding Metal Grating Weight Key Factors and Considerations

The type of grating refers to the specific design and manufacturing process employed. There are various types of metal grating, including welded, press-locked, and swaged grating. Welded grating, for example, offers high load-bearing capacity and rigidity, making it heavier than other types. On the other hand, press-locked grating might be lighter and less robust, making it suitable for less demanding applications.

metal grating weight

Thickness is another critical factor affecting the weight of metal grating. Thicker grating typically provides greater strength and load-bearing capabilities but also increases the overall weight. Designers must balance the need for durability and load resistance with the practicalities of installation and transportation. An excessively heavy grating may pose challenges in terms of handling and may require special equipment for installation, whereas a lighter grating could be easier to manage but might fall short in performance under heavy loads.

The pattern of the grating also plays a role in determining its weight. Gratings come in various styles, including rectangular, square, or custom-patterned designs. Different patterns will have varying amounts of material removed or used, consequently affecting the weight. For example, a grating with a larger open area will generally be lighter than one that is solid and densely packed.

Overall, understanding the weight of metal grating is essential for engineers, designers, and builders. It impacts not only the logistics of transportation and installation but also the safety and functionality of the final product. By considering material, type, thickness, and design, professionals can select the right metal grating for their specific needs, ensuring both performance and durability in their applications. As industries continue to evolve, the demand for advanced metal grating solutions that balance weight and strength will likely drive innovations in this vital sector.

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024