- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

2 月 . 01, 2025 01:41

Back to list

metal grating sizes

Metal grating sizes play a crucial role in industries ranging from architecture to manufacturing, providing solutions for flooring, stair treads, platforms, and more. Selecting the correct size of metal grating can lead to enhanced safety, performance, and cost-effectiveness. This article explores the intricacies of metal grating sizes, offering insights based on experience, expertise, authoritativeness, and trustworthiness.

5. Custom Sizing For unique applications, grating can be custom-sized to fit specific spaces or support unique loads. Many manufacturers offer customization options, accommodating variations in panel size, bearing bars, and spacing to fit specific engineering designs and architectural aesthetics. Expert Advice and Applications Choosing the right size of metal grating requires expertise and an understanding of the intended application. Consult with engineering professionals or manufacturers to ensure that you select the right grating size for your needs. It's crucial to consider load ratings, environmental conditions, and safety standards when determining the appropriate grating size. For instance, industrial settings with heavy-duty trucks passing through will require stronger, thicker gratings with wider bearing bars and tighter spacing. Meanwhile, architectural applications prioritizing aesthetic appeal may lean towards specific patterns and thinner materials. Ensuring Authoritativeness and Trustworthiness When selecting metal grating, source materials from reputable manufacturers known for high-quality production standards and reliable customer service. Companies that adhere to industry standards, such as those set by the American National Standards Institute (ANSI) or Occupational Safety and Health Administration (OSHA), offer assurance of safety, durability, and compliance. According to industry experts, utilizing standardized sizes when possible reduces costs and simplifies installation, although custom solutions should not be overlooked when standard sizes cannot meet project requirements. Conclusion By understanding the detailed aspects of metal grating sizes—ranging from panel dimensions to bar spacing and thickness—one can effectively choose the most suitable grating for a variety of industrial applications. Prioritize consultation with experts and reliable suppliers to ensure longevity, efficiency, and safety. Leveraging the right grating size can significantly impact both the functionality and aesthetic of any project, enhancing the overall structural performance and visionary design.

5. Custom Sizing For unique applications, grating can be custom-sized to fit specific spaces or support unique loads. Many manufacturers offer customization options, accommodating variations in panel size, bearing bars, and spacing to fit specific engineering designs and architectural aesthetics. Expert Advice and Applications Choosing the right size of metal grating requires expertise and an understanding of the intended application. Consult with engineering professionals or manufacturers to ensure that you select the right grating size for your needs. It's crucial to consider load ratings, environmental conditions, and safety standards when determining the appropriate grating size. For instance, industrial settings with heavy-duty trucks passing through will require stronger, thicker gratings with wider bearing bars and tighter spacing. Meanwhile, architectural applications prioritizing aesthetic appeal may lean towards specific patterns and thinner materials. Ensuring Authoritativeness and Trustworthiness When selecting metal grating, source materials from reputable manufacturers known for high-quality production standards and reliable customer service. Companies that adhere to industry standards, such as those set by the American National Standards Institute (ANSI) or Occupational Safety and Health Administration (OSHA), offer assurance of safety, durability, and compliance. According to industry experts, utilizing standardized sizes when possible reduces costs and simplifies installation, although custom solutions should not be overlooked when standard sizes cannot meet project requirements. Conclusion By understanding the detailed aspects of metal grating sizes—ranging from panel dimensions to bar spacing and thickness—one can effectively choose the most suitable grating for a variety of industrial applications. Prioritize consultation with experts and reliable suppliers to ensure longevity, efficiency, and safety. Leveraging the right grating size can significantly impact both the functionality and aesthetic of any project, enhancing the overall structural performance and visionary design.

Share

Prev:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

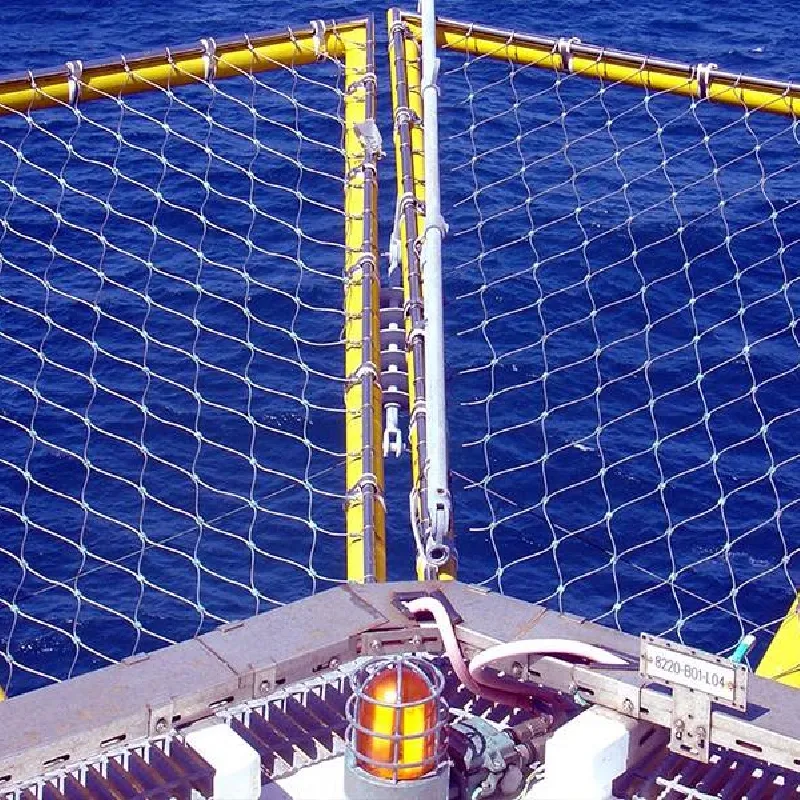

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024