- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Understanding Various Dimensions of Metal Grating for Your Project Needs

Understanding Metal Grating Sizes A Comprehensive Overview

Metal grating is a vital component in various industries and applications, valued for its durability, strength, and versatility. Its uses range from flooring solutions to drainage systems, and it plays a key role in safety, accessibility, and efficiency. Understanding the various sizes of metal grating is essential for selecting the right type for your specific needs.

Types of Metal Grating

There are several types of metal grating, with steel, aluminum, and stainless steel being the most common materials. Each type comes with its unique properties and is suited for different applications. For instance, steel grating is known for its strength and cost-effectiveness, making it ideal for heavy-duty applications, while aluminum grating is lightweight and resistant to corrosion, perfect for environments where weight and rust can be an issue.

Common Sizes of Metal Grating

Metal grating sizes can vary widely, but they are typically categorized by their width, length, and thickness. The most commonly seen grating panels are several feet in length and width, often available in increments of 2, 3, or 4 feet. Thickness commonly ranges from 1/8 inch to 3/8 inch, depending on the application and load requirements.

The spacing between the bars, or the open area, is another critical size factor to consider. Standard spacing is usually around 1-inch, but this can be adjusted based on specific requirements, such as safety regulations, environmental conditions, and property usage. Higher open area designs allow for better drainage and airflow, making them ideal for use in areas prone to water accumulation.

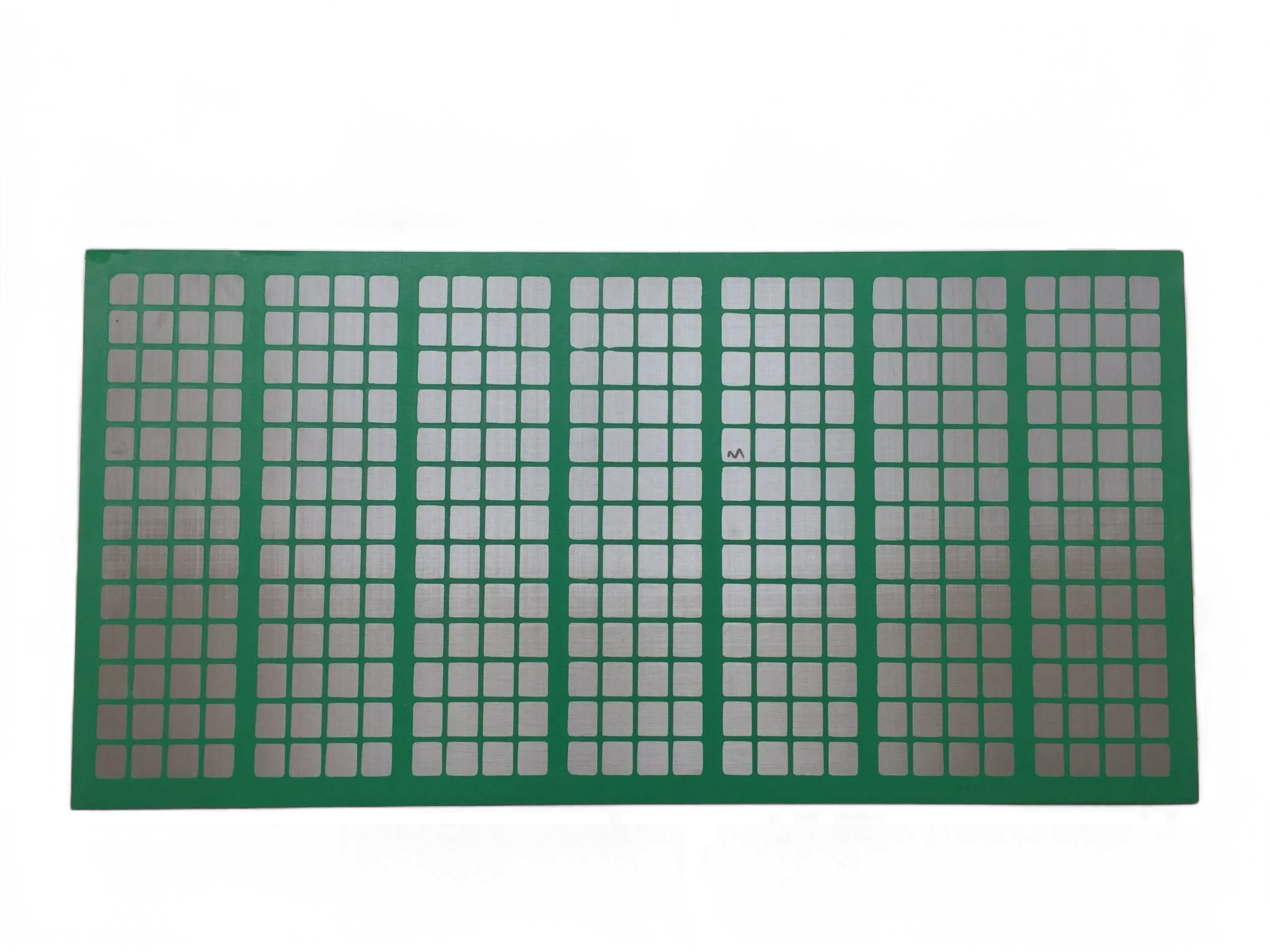

metal grating sizes

Selecting the Right Size

When selecting the appropriate metal grating size for a project, several factors come into play. The load capacity required should be the primary consideration, as different applications demand varying levels of strength. For example, industrial settings often require heavier and thicker gratings to support substantial machinery and foot traffic, while lighter applications, such as walkways and public access paths, may only need thinner grating for pedestrian use.

Another critical aspect to evaluate is the installation area. The dimensions of the space where the grating will be installed will significantly influence size selection. Proper fit and alignment should always be maintained to ensure safety and functionality. For custom or unique spacing requirements, many manufacturers offer the option of bespoke sizes to meet specific design needs.

Benefits of Using the Correct Size

Using the correct size of metal grating has numerous benefits, including enhanced safety levels and improved durability. Properly sized grating minimizes the risk of accidents, particularly in high-traffic areas, while ensuring structural integrity over time. Additionally, correct sizing can lead to cost savings by reducing unnecessary material waste and the expenses associated with repairs or replacements.

Conclusion

In conclusion, understanding metal grating sizes is essential for ensuring optimal performance and safety in various applications. By considering the type of material, the specific dimensions required, and the intended use, you can select the right grating that meets your needs effectively. From industrial settings to commercial spaces, the right metal grating contributes significantly to both functionality and safety, making it a crucial element in modern infrastructure.

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024