- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

3 月 . 06, 2025 14:10

Back to list

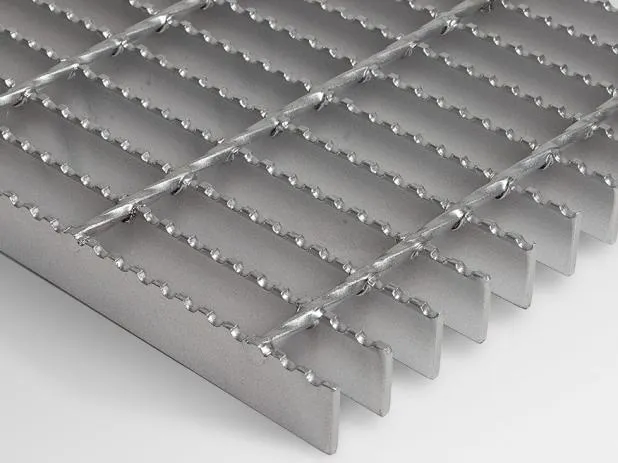

metal grating for sale

Understanding the dynamics of metal grating pricing is crucial for anyone in the construction, industrial, or fabrication sectors. Metal gratings are indispensable due to their durability, versatility, and strength, providing an integral aspect of architecture and infrastructure development. Here’s a comprehensive examination of factors that influence metal grating prices and how this knowledge can aid in making informed purchasing decisions.

Regulatory and Compliance Factors Compliance with national and international safety and quality standards can add layers of cost due to the necessary testing and certifications. However, this ensures that the product meets rigorous safety requirements, offering better reliability and assurance in quality. Investing in compliant products may initially cost more but can save money long-term by avoiding potential regulatory penalties and ensuring durability. Supplier Reputation and Experience Suppliers with a proven track record and significant industry experience often charge premium prices for their products and services. Their expertise in delivering high-quality metal gratings can justify their pricing, as it often translates to reduced risk of product failure and better service. Building a relationship with reputable suppliers can result in better pricing, reliable delivery schedules, and higher-quality products. The Role of Distribution and Logistics The logistics involved in transporting heavy, large-volume metal gratings also impact the final price. Proximity to the manufacturing hub can reduce transportation costs, offering more competitive pricing. Moreover, efficient logistics solutions provided by suppliers can minimize delivery times, thereby reducing the potential financial implications of project delays. Conclusion When navigating metal grating prices, it is crucial to evaluate all influencing factors, from material quality to production techniques and market dynamics. Leveraging this knowledge can lead to more strategic procurement choices. Understanding these variables allows businesses to negotiate effectively with suppliers, ensuring they receive the best value for their investment. As global market conditions evolve, consistently reviewing these factors is vital to maintaining competitive advantage and maximizing the longevity and reliability of your metal grating needs.

Regulatory and Compliance Factors Compliance with national and international safety and quality standards can add layers of cost due to the necessary testing and certifications. However, this ensures that the product meets rigorous safety requirements, offering better reliability and assurance in quality. Investing in compliant products may initially cost more but can save money long-term by avoiding potential regulatory penalties and ensuring durability. Supplier Reputation and Experience Suppliers with a proven track record and significant industry experience often charge premium prices for their products and services. Their expertise in delivering high-quality metal gratings can justify their pricing, as it often translates to reduced risk of product failure and better service. Building a relationship with reputable suppliers can result in better pricing, reliable delivery schedules, and higher-quality products. The Role of Distribution and Logistics The logistics involved in transporting heavy, large-volume metal gratings also impact the final price. Proximity to the manufacturing hub can reduce transportation costs, offering more competitive pricing. Moreover, efficient logistics solutions provided by suppliers can minimize delivery times, thereby reducing the potential financial implications of project delays. Conclusion When navigating metal grating prices, it is crucial to evaluate all influencing factors, from material quality to production techniques and market dynamics. Leveraging this knowledge can lead to more strategic procurement choices. Understanding these variables allows businesses to negotiate effectively with suppliers, ensuring they receive the best value for their investment. As global market conditions evolve, consistently reviewing these factors is vital to maintaining competitive advantage and maximizing the longevity and reliability of your metal grating needs.

Share

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024