- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Cost Analysis of Metal Grating Materials for Construction Projects

Understanding Metal Grating Prices Factors Influencing Costs

Metal grating is an essential component in various industrial applications, serving as flooring, walkways, and platforms. Its durable nature makes it a preferred choice in industries such as construction, oil and gas, marine, and transportation. However, one common question that arises for businesses and contractors is what drives the price of metal grating?

Materials Used

The primary factor affecting the price of metal grating is the material used in its production. Common materials include carbon steel, stainless steel, aluminum, and fiberglass, each offering different properties and levels of durability. Stainless steel, for example, is more resistant to corrosion and rust, making it ideal for environments exposed to moisture or chemicals, but it comes with a higher price tag. Aluminum is lightweight and resistant to corrosion but generally less strong than steel. Understanding the specific needs of your project will go a long way in determining which material is the most cost-effective.

Manufacturing Process

The method of manufacturing also plays a significant role in pricing. Metal grating can be produced through various techniques such as welding, swage-locking, or casting. Each process has its own cost implications; for instance, welded grating is generally less expensive than cast grating, which is often used for custom designs and high-load scenarios. The complexity of the design, including the spacing and thickness of the bars, will also influence the final price.

Dimensions and Specifications

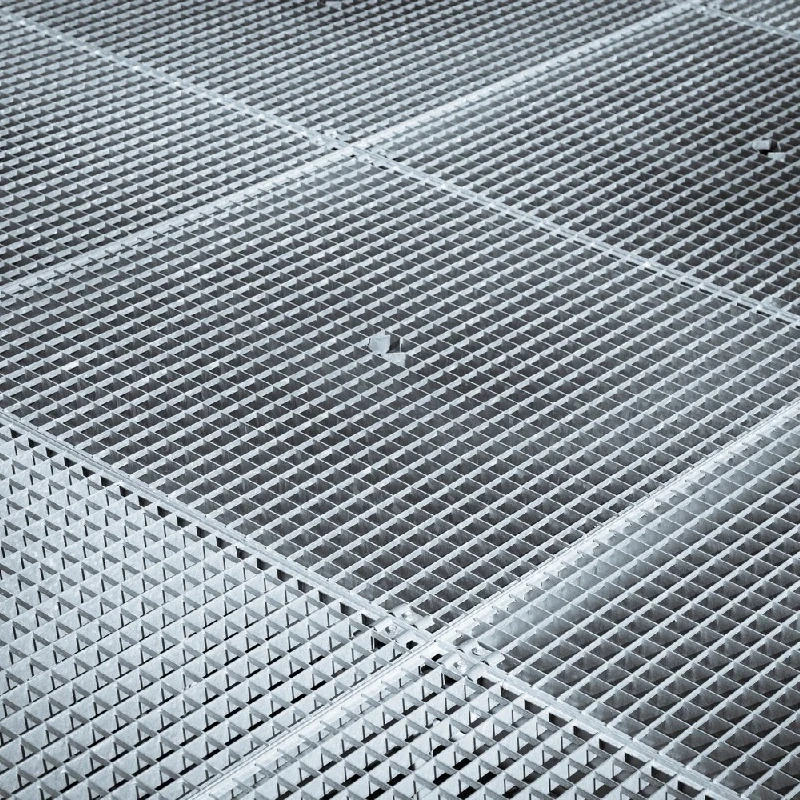

metal grating price

Prices can vary significantly based on dimensions and specifications. Standard sizes may be available at lower costs due to mass production, while custom-sized grating will typically be more expensive due to additional machining and handling required. The depth and load-bearing capacity chosen for the grating can also affect pricing, as thicker materials and higher load ratings usually require more material and labor.

Market Demand and Supply

Market dynamics, including demand and supply, can impact prices as well. During periods of high construction activity or global supply chain disruptions, the cost of raw materials may rise, thereby pushing up the prices of metal grating. Conversely, during periods of lower demand, prices may stabilize or even decrease. Keeping an eye on market trends can help businesses make informed decisions about when to purchase metal grating.

Additional Costs

When budgeting for metal grating, it’s important to consider additional costs such as shipping, installation, and maintenance. Transportation costs can vary based on the distance to the project site, and larger or heavier grating panels may incur higher shipping fees. Installation costs will also vary depending on the complexity of the project and labor rates in the area.

Conclusion

In summary, the price of metal grating is influenced by a variety of factors, including material selection, manufacturing methods, dimensions, market conditions, and additional associated costs. By understanding these elements, businesses and contractors can make informed choices that align with their budget and project requirements. Investing time in researching and comparing options will ultimately lead to better value and satisfaction in metal grating purchases.

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024