- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

2 月 . 14, 2025 03:35

Back to list

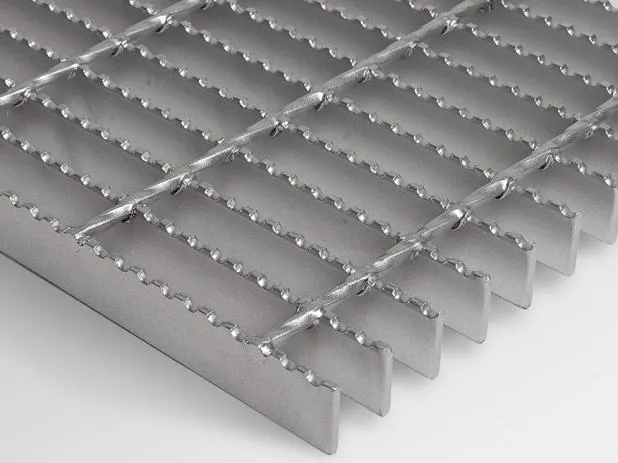

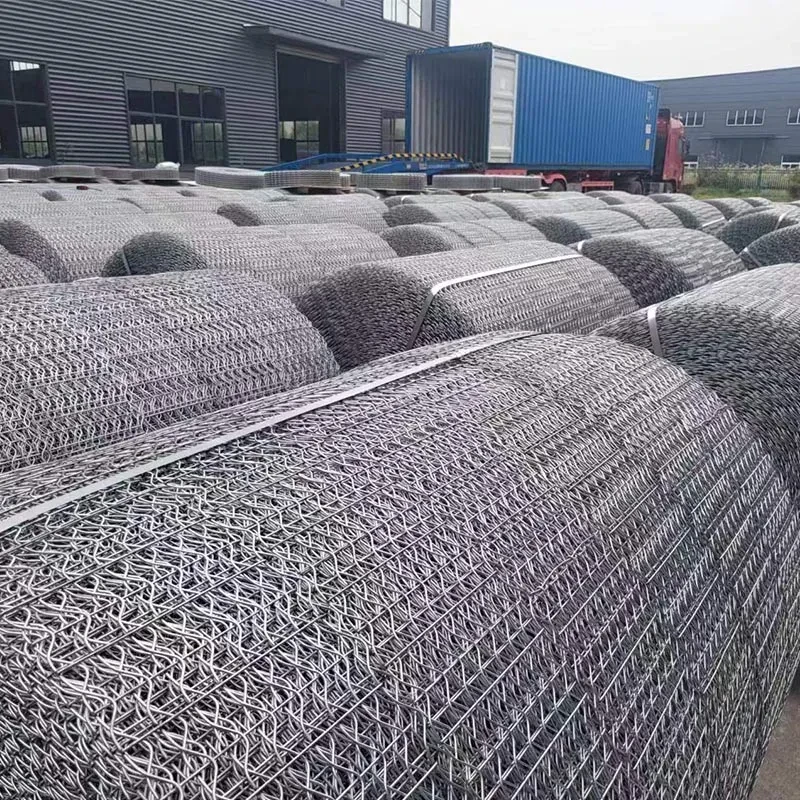

metal grating for sale

Choosing the right metal drain grating for your construction project can make a world of difference in functionality, safety, and aesthetic appeal. Driven by years of experience in construction and product development, here, we delve into why selecting the ideal metal drain grating requires more than a fleeting consideration and how it can profoundly impact your results.

In creating a reliable water management system, attention to environmental sustainability has become more pronounced. Opting for metal gratings with a lower carbon footprint or made from recycled materials reflects a commitment to sustainability, resonating well with ESG (Environmental, Social, Corporate Governance) metrics that have become an industry standard. This aligns with authoritative expectations in construction today. Developers and planners are increasingly looking beyond immediate needs toward long-term sustainability and corporate responsibility. By choosing materials and methods that support these values, one can not only achieve structural efficacy but also boost market trustworthiness, aligning with modern consumer consciousness. Trustworthiness in construction and design cannot be overstated. Sourcing gratings from reputable manufacturers known for ethical practices and quality control ensures significant confidence in the product's performance. Reviewing certifications and testing results can preemptively address potential compliance issues with local regulations or safety standards. Building credibility through consumer reviews and case studies of projects where specific metal drain gratings were employed can showcase not only the product’s utility but also reassure clients and stakeholders of their investment's security. By illustrating past successes and long-term benefits, trust is cultivated, which can be pivotal for future contracts or projects. In summary, when considering metal drain gratings, experience indicates that coupling the right material with professional installation and sustainable practices can yield unmatched results. Expertise in selecting suitable materials, acknowledging environmental impacts, and ensuring regulatory compliance elevates a project from mere construction to forward-thinking, trusted development. Whether you’re addressing safety concerns, aesthetic desires, or environmental responsibilities, the right choice can lead to enduring success, meeting both contemporary and future demands.

In creating a reliable water management system, attention to environmental sustainability has become more pronounced. Opting for metal gratings with a lower carbon footprint or made from recycled materials reflects a commitment to sustainability, resonating well with ESG (Environmental, Social, Corporate Governance) metrics that have become an industry standard. This aligns with authoritative expectations in construction today. Developers and planners are increasingly looking beyond immediate needs toward long-term sustainability and corporate responsibility. By choosing materials and methods that support these values, one can not only achieve structural efficacy but also boost market trustworthiness, aligning with modern consumer consciousness. Trustworthiness in construction and design cannot be overstated. Sourcing gratings from reputable manufacturers known for ethical practices and quality control ensures significant confidence in the product's performance. Reviewing certifications and testing results can preemptively address potential compliance issues with local regulations or safety standards. Building credibility through consumer reviews and case studies of projects where specific metal drain gratings were employed can showcase not only the product’s utility but also reassure clients and stakeholders of their investment's security. By illustrating past successes and long-term benefits, trust is cultivated, which can be pivotal for future contracts or projects. In summary, when considering metal drain gratings, experience indicates that coupling the right material with professional installation and sustainable practices can yield unmatched results. Expertise in selecting suitable materials, acknowledging environmental impacts, and ensuring regulatory compliance elevates a project from mere construction to forward-thinking, trusted development. Whether you’re addressing safety concerns, aesthetic desires, or environmental responsibilities, the right choice can lead to enduring success, meeting both contemporary and future demands.

Share

Prev:

Next:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024