- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

1 月 . 22, 2025 01:16

Back to list

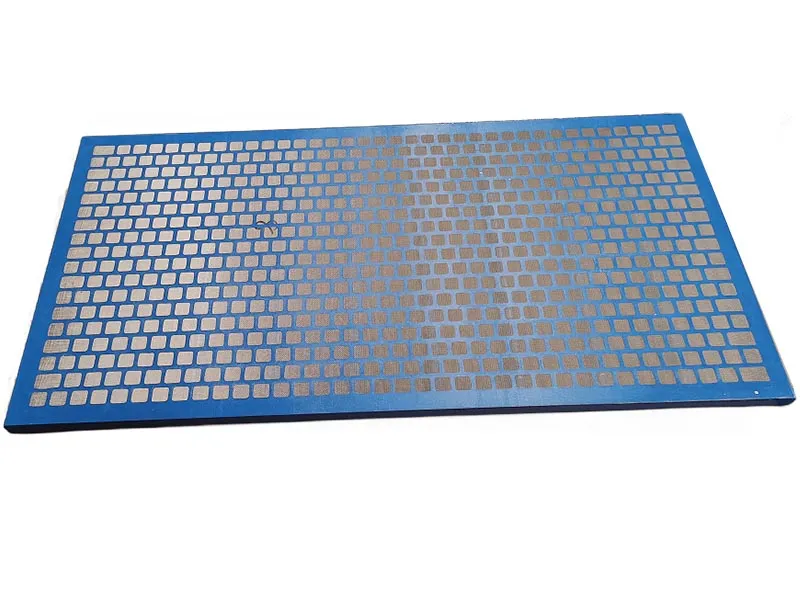

metal catwalk grating

Metal catwalk grating is revolutionizing the industrial flooring sector with its unparalleled blend of durability, safety, and versatility. The grating is made from a variety of metals, including steel, aluminum, and stainless steel, ensuring that it caters to a wide array of industrial applications. These materials are chosen not just for their strength, but also for their ability to withstand harsh environmental conditions without degrading.

Beyond safety and strength, metal catwalk grating offers exceptional versatility. It is available in various sizes and configurations, allowing it to be tailored to specific industrial requirements. Whether it's for creating walkways, platforms, or stair treads, the adaptability of metal catwalk grating ensures that it can meet diverse application needs without compromising on performance. The ease of maintenance is another tangible benefit that users of metal catwalk grating frequently report. Unlike wooden or poorly made alternatives that may require frequent repairs or replacements, metal catwalk grating is designed to last, significantly reducing maintenance efforts and costs over time. Its ability to withstand extreme temperatures, chemical exposure, and heavy usage without showing signs of wear and tear makes it a cost-effective solution for conglomerates aiming to maximize their operational efficiency. Moreover, given the increasing importance of sustainability in today's industrial practices, the recyclability of metal catwalk grating stands out as a key feature. Companies are more inclined to choose environmentally responsible products, and metal catwalk grating fits this criterion as it can be recycled at the end of its lifespan, thereby reducing its environmental footprint. Overall, the innovative design, compliance with rigorous safety standards, and long-lasting performance of metal catwalk grating make it an indispensable asset in the industrial sector. Companies looking to enhance their operational infrastructures owe it to themselves to consider the myriad benefits provided by this outstanding product. By integrating metal catwalk grating into their facilities, businesses not only make a commitment to safety and efficiency but also fortify their position as forward-thinking leaders in the industrial landscape.

Beyond safety and strength, metal catwalk grating offers exceptional versatility. It is available in various sizes and configurations, allowing it to be tailored to specific industrial requirements. Whether it's for creating walkways, platforms, or stair treads, the adaptability of metal catwalk grating ensures that it can meet diverse application needs without compromising on performance. The ease of maintenance is another tangible benefit that users of metal catwalk grating frequently report. Unlike wooden or poorly made alternatives that may require frequent repairs or replacements, metal catwalk grating is designed to last, significantly reducing maintenance efforts and costs over time. Its ability to withstand extreme temperatures, chemical exposure, and heavy usage without showing signs of wear and tear makes it a cost-effective solution for conglomerates aiming to maximize their operational efficiency. Moreover, given the increasing importance of sustainability in today's industrial practices, the recyclability of metal catwalk grating stands out as a key feature. Companies are more inclined to choose environmentally responsible products, and metal catwalk grating fits this criterion as it can be recycled at the end of its lifespan, thereby reducing its environmental footprint. Overall, the innovative design, compliance with rigorous safety standards, and long-lasting performance of metal catwalk grating make it an indispensable asset in the industrial sector. Companies looking to enhance their operational infrastructures owe it to themselves to consider the myriad benefits provided by this outstanding product. By integrating metal catwalk grating into their facilities, businesses not only make a commitment to safety and efficiency but also fortify their position as forward-thinking leaders in the industrial landscape.

Share

Prev:

Next:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024