- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

1 月 . 28, 2025 06:00

Back to list

Welded Steel Grating

Metal bar grating is a critical component in a variety of industrial and commercial applications due to its combination of strength, durability, and versatility. With a wide range of materials, styles, and configurations, understanding the nuances of metal bar grating can greatly enhance both the safety and efficiency of projects.

Safety considerations further justify the deployment of metal bar grating in areas prone to slipperiness, especially in locations exposed to oils, water, or other lubricants. The grating allows for the quick drainage of liquids, reducing slip hazards and providing a stable surface for walking. In high-risk environments, this feature is not only practical but crucial to workplace safety compliance. Moreover, the maintenance of metal bar grating is straightforward, owing to its open grid design that permits easy cleaning and waste removal. Periodic maintenance ensures longevity, maintaining the functionality and appearance of the grating. This advantage underlines its cost-effectiveness over its lifecycle, as the need for replacement is minimized when compared to solid surface alternatives. From an environmental standpoint, metal bar grating aligns well with sustainable practices. Many grating products are produced with recyclable materials, reducing the ecological footprint. Additionally, its durability translates to less frequent replacements and, consequently, less waste generation in the long term. In recent years, the incorporation of metal bar grating in architectural design has highlighted its aesthetic versatility. Modern architecture often employs grating as a design element, allowing natural light and ventilation while maintaining structural integrity. Its use in public infrastructure not only ensures functionality but brings about a unique blend of form and function, enhancing urban landscapes. In conclusion, metal bar grating serves as an indispensable element in modern industrial and commercial infrastructures. By combining strength, versatility, and an array of material options, it meets demands for both safety and efficiency across diverse applications. Its low maintenance needs and eco-friendly nature further establish metal bar grating as a wise choice for long-term, effective structural solutions. With proper knowledge and installation, metal bar grating can significantly enhance the functionality and safety of any project it accommodates.

Safety considerations further justify the deployment of metal bar grating in areas prone to slipperiness, especially in locations exposed to oils, water, or other lubricants. The grating allows for the quick drainage of liquids, reducing slip hazards and providing a stable surface for walking. In high-risk environments, this feature is not only practical but crucial to workplace safety compliance. Moreover, the maintenance of metal bar grating is straightforward, owing to its open grid design that permits easy cleaning and waste removal. Periodic maintenance ensures longevity, maintaining the functionality and appearance of the grating. This advantage underlines its cost-effectiveness over its lifecycle, as the need for replacement is minimized when compared to solid surface alternatives. From an environmental standpoint, metal bar grating aligns well with sustainable practices. Many grating products are produced with recyclable materials, reducing the ecological footprint. Additionally, its durability translates to less frequent replacements and, consequently, less waste generation in the long term. In recent years, the incorporation of metal bar grating in architectural design has highlighted its aesthetic versatility. Modern architecture often employs grating as a design element, allowing natural light and ventilation while maintaining structural integrity. Its use in public infrastructure not only ensures functionality but brings about a unique blend of form and function, enhancing urban landscapes. In conclusion, metal bar grating serves as an indispensable element in modern industrial and commercial infrastructures. By combining strength, versatility, and an array of material options, it meets demands for both safety and efficiency across diverse applications. Its low maintenance needs and eco-friendly nature further establish metal bar grating as a wise choice for long-term, effective structural solutions. With proper knowledge and installation, metal bar grating can significantly enhance the functionality and safety of any project it accommodates.

Share

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

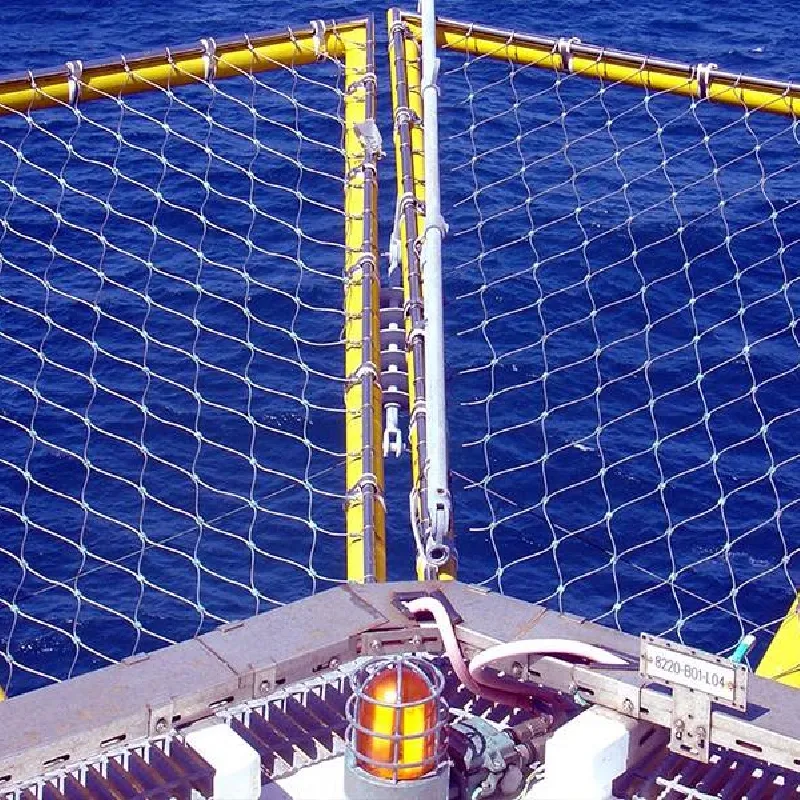

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024