- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Leading Manufacturers of High-Quality Shale Shaker Screens for Reliable Oil and Gas Operations

The Importance of Shale Shaker Screens in the Drilling Industry

Shale shakers are vital components in the drilling industry, particularly in the exploration and extraction of oil and gas. They serve the crucial function of separating cuttings from drilling fluids, ensuring that the fluid can be reused in the drilling process without contamination. At the heart of any shale shaker is the shaker screen, which plays a pivotal role in maintaining the efficiency and effectiveness of the entire operation.

The Function of Shale Shaker Screens

Shaker screens come in various types and configurations, designed to optimize the separation of solids from fluids. They are typically made from woven wire or synthetic materials and are engineered to withstand the harsh conditions encountered in drilling operations. The primary function of these screens is to filter out unwanted solids while allowing the drilling fluid to pass through. This not only helps in keeping the drilling fluid clean but also prolongs the life of the equipment downstream.

Types of Shale Shaker Screens

There are different types of shaker screens available, catering to various drilling applications. Some common types include

1. Wire Mesh Screens These traditional screens are made from woven wire and can vary in mesh size, allowing for different filtration capabilities. They are often used in less demanding applications.

2. Composite Screens These screens combine woven wire with synthetic materials, providing greater durability and a higher degree of separation efficiency. They are particularly effective in applications where high throughput and longer screen life are critical.

3. Hook Strip Screens These screens feature a hook strip design, allowing for easy installation and removal. Hook strip screens are widely used due to their versatility and ease of use.

shale shakerscreen manufacturers

4. Rubber Screens Often utilized in conjunction with metal or composite screens, rubber screens can absorb impact and enhance the durability of the shaker. They are especially useful in abrasive drilling environments.

Choosing the Right Manufacturer

When it comes to selecting shaker screens, the choice of manufacturer is crucial. Reliable shale shaker screen manufacturers offer various options that meet industry standards and regulations. The best manufacturers invest in research and development to create innovative products that enhance drilling performance. They also ensure that their screens are tested for quality and durability.

A reputable manufacturer will provide detailed information on the specifications of their screens, including dimensions, mesh sizes, and compatibility with various shaker models. They should also offer warranties and support services to help users troubleshoot any issues that might arise during operation.

The Future of Shale Shaker Screens

As the industry evolves, so too does technology in shale shaker screens. Innovations such as advanced materials, automated monitoring systems, and more efficient design processes are on the horizon. These developments aim to improve the separation efficiency and reduce the environmental impact of drilling operations.

Furthermore, as regulatory standards become more stringent, the demand for high-quality, reliable shaker screens will increase, pushing manufacturers to innovate continually. The integration of data analytics and machine learning into drilling operations presents an exciting opportunity for manufacturers to advance the capabilities of shale shakers and their screens.

Conclusion

In summary, shale shaker screens are integral to the efficiency and effectiveness of the drilling process in the oil and gas industry. The choice of manufacturer, along with the type and durability of the screens, significantly impacts drilling performance and cost-effectiveness. As technology advances, the future of shale shaker screens looks promising, with opportunities for enhanced performance and sustainability in drilling operations. For anyone involved in the drilling industry, understanding the importance of shaker screens and staying updated on the latest innovations is key to success in this competitive field.

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

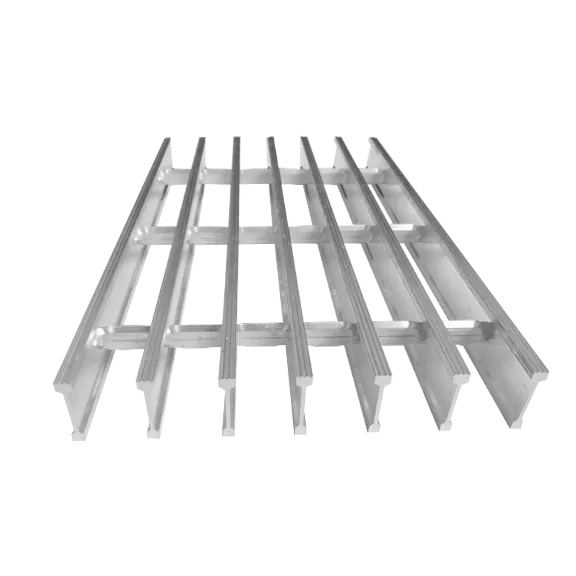

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024