- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

1 月 . 15, 2025 09:16

Back to list

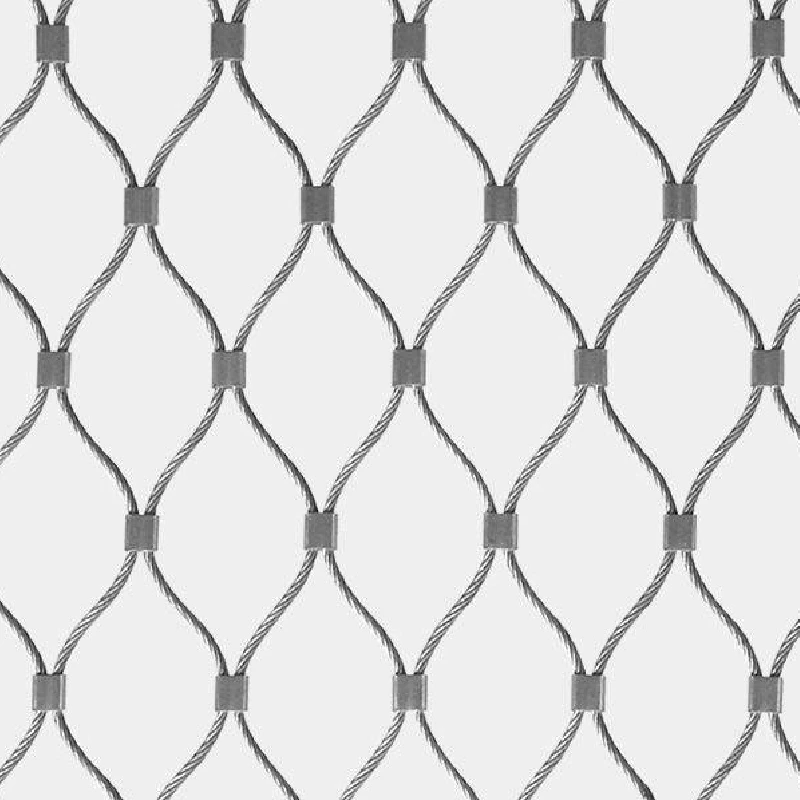

perimeter safety net

Landing safety nets are a critical aspect of modern aerial operations, providing essential protection and peace of mind for both professionals and enthusiasts in various fields. These nets are ingeniously designed to cushion and secure, ensuring that what goes up safely returns to earth without incident. With significant advances in materials and technology, they have become indispensable in ensuring safety in disciplines that involve height and flight.

In the construction industry, landing safety nets provide a different but equally vital role. For workers on multi-story projects, these nets catch equipment and debris that may accidentally fall, preventing injury to those below and minimizing equipment damage. Having seen real-world applications and testimonials, construction managers are convinced of their value—not just as a safety tool but as a money-saving investment given the potential cost of human error. For both aviation and construction, the field’s leaders provide case studies and research papers that outline the benefits and technology behind landing safety nets. Peer-reviewed articles contribute to the collective knowledge, allowing for data-backed decisions in high-stakes environments. A notable advancement includes smart landing safety nets integrated with sensors. These sensors detect the velocity and weight of falling objects, providing data that helps refine procedural responses. Real-time alerts can allow for faster reaction times, reducing the chance of harm or damage. In conclusion, landing safety nets embody the core principles of experience, expertise, authoritativeness, and trustworthiness. Their development and implementation rely on cutting-edge technology, years of fieldwork, and the commitment to safety above all else. As industries continue to evolve, so too will these indispensable safety tools, always aiming to create safer environments conducive to both innovation and protection.

In the construction industry, landing safety nets provide a different but equally vital role. For workers on multi-story projects, these nets catch equipment and debris that may accidentally fall, preventing injury to those below and minimizing equipment damage. Having seen real-world applications and testimonials, construction managers are convinced of their value—not just as a safety tool but as a money-saving investment given the potential cost of human error. For both aviation and construction, the field’s leaders provide case studies and research papers that outline the benefits and technology behind landing safety nets. Peer-reviewed articles contribute to the collective knowledge, allowing for data-backed decisions in high-stakes environments. A notable advancement includes smart landing safety nets integrated with sensors. These sensors detect the velocity and weight of falling objects, providing data that helps refine procedural responses. Real-time alerts can allow for faster reaction times, reducing the chance of harm or damage. In conclusion, landing safety nets embody the core principles of experience, expertise, authoritativeness, and trustworthiness. Their development and implementation rely on cutting-edge technology, years of fieldwork, and the commitment to safety above all else. As industries continue to evolve, so too will these indispensable safety tools, always aiming to create safer environments conducive to both innovation and protection.

Share

Next:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

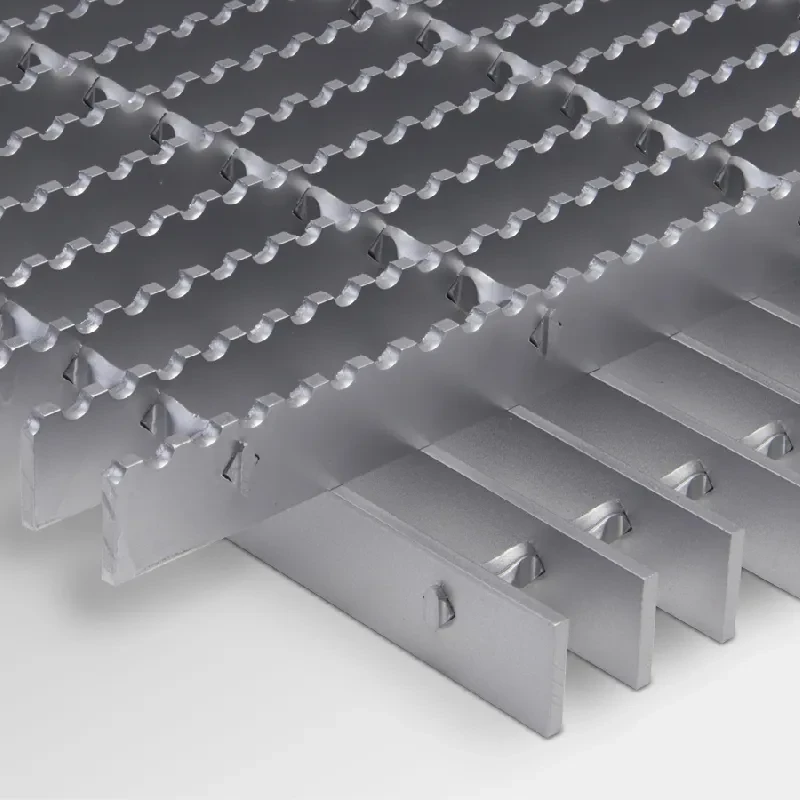

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024