- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

2 月 . 13, 2025 09:53

Back to list

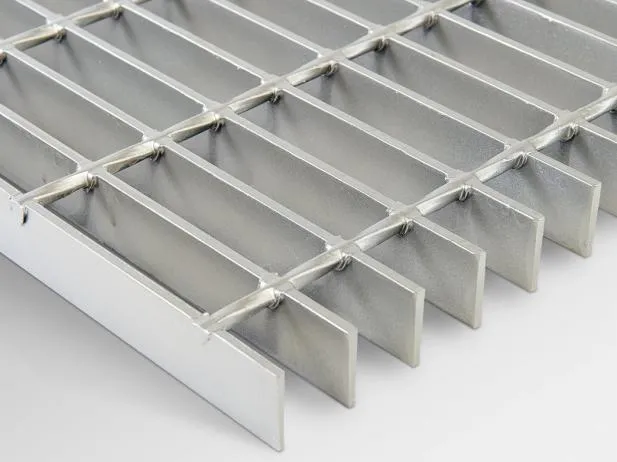

industrial shaker screen

Industrial shaker screens play a critical role in a wide array of industries, including oil and gas, mining, and construction. These screens are essential for the separation of solids from liquids, particularly in the drilling and mining industries. Understanding the importance, functionality, and technological advancements in industrial shaker screens can significantly enhance operational efficiency and product quality.

Professional expertise in the field emphasizes the critical role of screen aperture size. Aperture size directly impacts a screen's filtering capability and the quality of the separation achieved. A professional approach involves conducting thorough particle size analysis to determine the optimal aperture size for a given application. By doing so, operators can optimize efficiency, enhance the recovery of valuable materials, and minimize environmental impact through reduced waste. Authoritative sources underline the significance of maintenance and proper screen handling. Regular maintenance protocols such as cleaning, inspection, and timely replacement of worn-out screens are vital to ensure consistent performance. Well-maintained screens not only enhance productivity but also extend the overall lifespan of the equipment, contributing to long-term operational savings. Trustworthiness in industrial shaker screen solutions is built on transparent supplier relationships and stringent quality assurance measures. Trusted suppliers provide detailed product specifications and performance data, allowing operators to make informed decisions. Moreover, third-party testing and certifications further bolster credibility, ensuring that the screens meet industry standards and operate efficiently under specified conditions. Overall, industrial shaker screens are indispensable components in the realm of solid-liquid separation across multiple sectors. Their design, material selection, and technological advancements continue to evolve, driven by operational demands and environmental considerations. Operators who invest in high-quality screens not only achieve superior separation but also gain a competitive edge in their respective industries through improved efficiency and sustainability.

Professional expertise in the field emphasizes the critical role of screen aperture size. Aperture size directly impacts a screen's filtering capability and the quality of the separation achieved. A professional approach involves conducting thorough particle size analysis to determine the optimal aperture size for a given application. By doing so, operators can optimize efficiency, enhance the recovery of valuable materials, and minimize environmental impact through reduced waste. Authoritative sources underline the significance of maintenance and proper screen handling. Regular maintenance protocols such as cleaning, inspection, and timely replacement of worn-out screens are vital to ensure consistent performance. Well-maintained screens not only enhance productivity but also extend the overall lifespan of the equipment, contributing to long-term operational savings. Trustworthiness in industrial shaker screen solutions is built on transparent supplier relationships and stringent quality assurance measures. Trusted suppliers provide detailed product specifications and performance data, allowing operators to make informed decisions. Moreover, third-party testing and certifications further bolster credibility, ensuring that the screens meet industry standards and operate efficiently under specified conditions. Overall, industrial shaker screens are indispensable components in the realm of solid-liquid separation across multiple sectors. Their design, material selection, and technological advancements continue to evolve, driven by operational demands and environmental considerations. Operators who invest in high-quality screens not only achieve superior separation but also gain a competitive edge in their respective industries through improved efficiency and sustainability.

Share

Next:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024