- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

2 月 . 14, 2025 04:30

Back to list

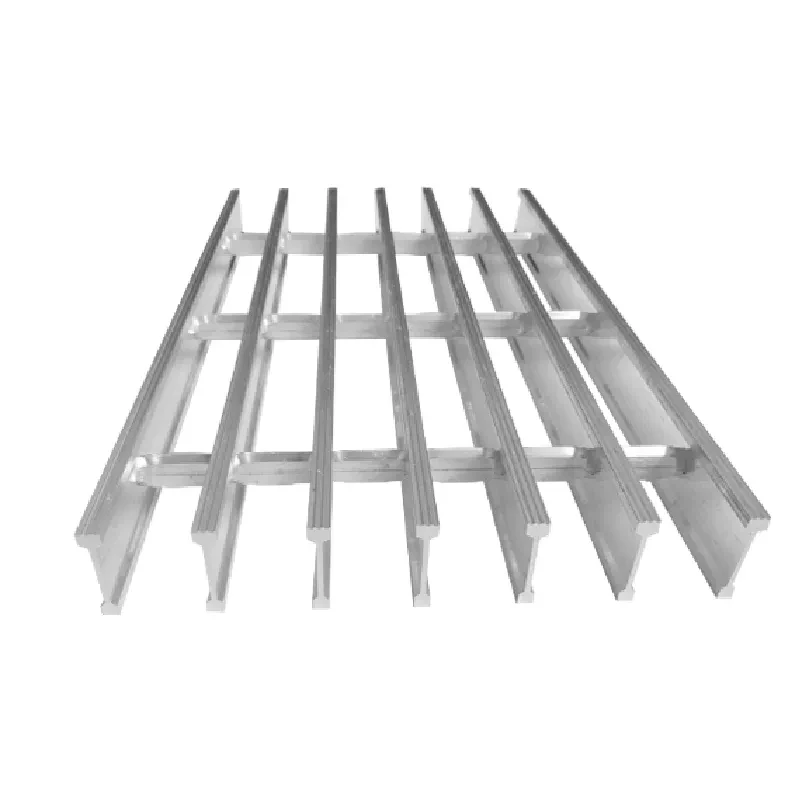

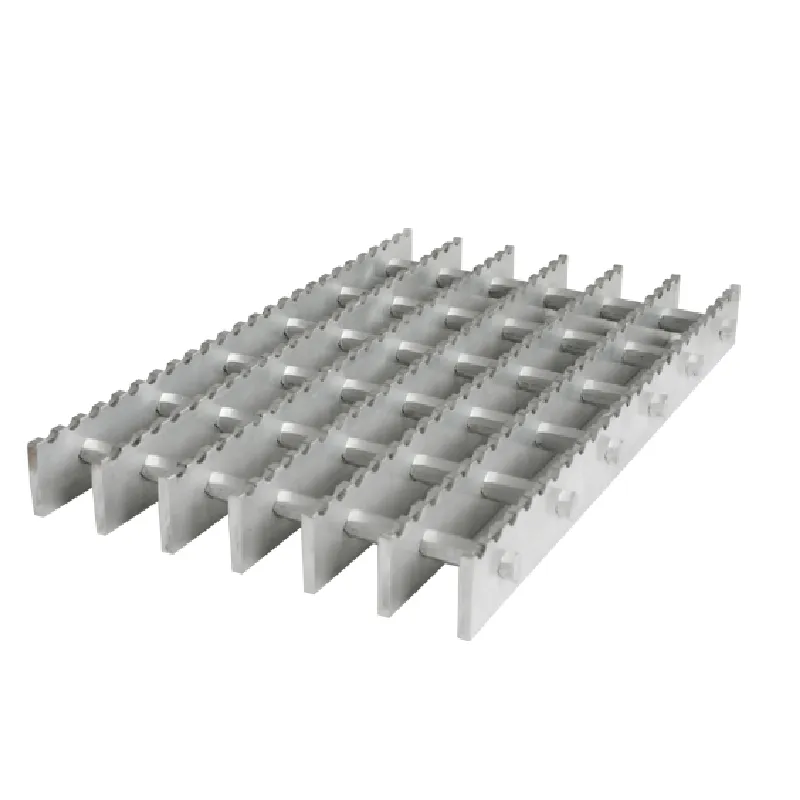

industrial steel grating

Industrial metal grating stands as a quintessential component in many architectural and industrial projects, offering not only functionality but also enhanced safety and durability. With years of evolution, this product has transcended traditional uses, presenting new opportunities for application across diverse industries. Here's a comprehensive exploration that delves into the features and benefits, backed by real-world experiences to underscore its value.

Furthermore, metal grating is environmentally friendly, aligning with growing sustainability efforts in modern construction. Its recyclable nature means it can be repurposed and reused, contributing to a circular economy. This aspect not only reduces waste but also positions companies as environment-conscious entities—a trait increasingly valued by stakeholders and clientele alike. In international markets, the demand for industrial metal grating is anticipated to rise, driven by developments in infrastructure and a shift towards more efficient industrial practices. Grating manufacturers are thus intensifying research and innovation to enhance product features, focusing on improving load capacity and corrosion resistance while optimizing cost-efficiency. Industry experts advocate for early adoption of these advances as they emerge, to remain competitive and ensure maximum return on investment. As with any critical structural component, quality assurance remains paramount. Leading manufacturers adhere to stringent quality control protocols, adhering to internationally recognized standards such as ISO 9001. This commitment to quality, coupled with thorough testing and certification, builds trust and reinforces the credibility of metal grating as a reliable solution. In conclusion, industrial metal grating embodies a blend of strength, adaptability, and sustainability, making it a cornerstone in industrial and architectural projects. Its proven track record of safety and performance, combined with expert endorsements, establishes it as a preferred choice across sectors. As industries continue to evolve, the role of metal grating in shaping safer, more efficient environments will undoubtedly expand, underlining its enduring value and versatility.

Furthermore, metal grating is environmentally friendly, aligning with growing sustainability efforts in modern construction. Its recyclable nature means it can be repurposed and reused, contributing to a circular economy. This aspect not only reduces waste but also positions companies as environment-conscious entities—a trait increasingly valued by stakeholders and clientele alike. In international markets, the demand for industrial metal grating is anticipated to rise, driven by developments in infrastructure and a shift towards more efficient industrial practices. Grating manufacturers are thus intensifying research and innovation to enhance product features, focusing on improving load capacity and corrosion resistance while optimizing cost-efficiency. Industry experts advocate for early adoption of these advances as they emerge, to remain competitive and ensure maximum return on investment. As with any critical structural component, quality assurance remains paramount. Leading manufacturers adhere to stringent quality control protocols, adhering to internationally recognized standards such as ISO 9001. This commitment to quality, coupled with thorough testing and certification, builds trust and reinforces the credibility of metal grating as a reliable solution. In conclusion, industrial metal grating embodies a blend of strength, adaptability, and sustainability, making it a cornerstone in industrial and architectural projects. Its proven track record of safety and performance, combined with expert endorsements, establishes it as a preferred choice across sectors. As industries continue to evolve, the role of metal grating in shaping safer, more efficient environments will undoubtedly expand, underlining its enduring value and versatility.

Share

Prev:

Next:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024