- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

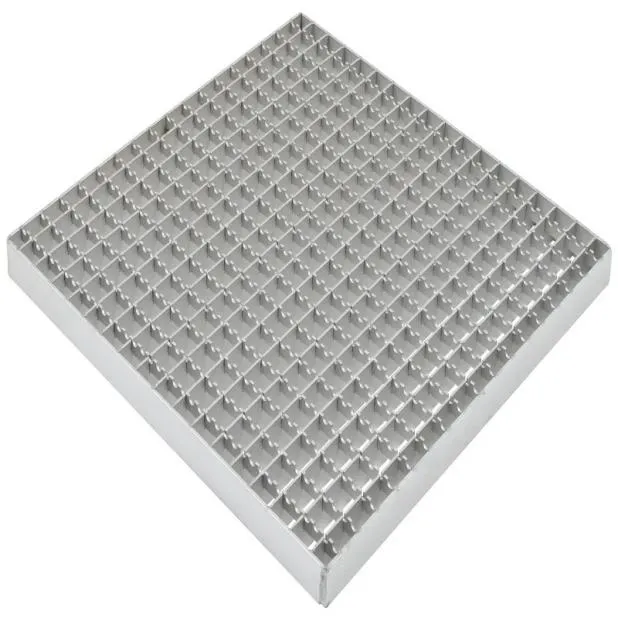

Durable Industrial Metal Grating Solutions for Improved Safety and Efficiency

The Versatility of Industrial Metal Grating A Comprehensive Overview

Industrial metal grating is a critical component in various industrial applications, providing safety, durability, and functionality across numerous sectors. Whether it's for flooring, walkways, or platforms, metal grating offers an ideal solution for efficient and safe industrial operations. In this article, we will explore the definition, types, benefits, and applications of industrial metal grating.

Definition and Types of Metal Grating

Metal grating is a construction material made from a series of parallel bars or plates, usually spaced evenly apart, to create a mesh structure. This can be fabricated from various materials including steel, aluminum, and stainless steel, based on the specific needs of the application.

There are several types of metal grating, each with unique characteristics

1. Bar Grating The most common form, where flat bars are welded or pressed together to create a grid. It can be customized in terms of spacing and dimensions.

2. Expanded Metal Grating This type is created by slitting and stretching metal sheets, which results in a lightweight and robust product. It provides excellent slip resistance and drainage, making it ideal for outdoor applications.

3. Perforated Metal Grating This variety features numerous holes punched into the metal sheet, allowing for enhanced light and air flow. Its strength and customizability make it popular in various applications.

4. Welded Wire Grating Made of intersecting wires that are welded together, this type of grating is often used for security purposes, as it provides a strong barrier while still allowing visibility.

Benefits of Metal Grating

The advantages of industrial metal grating are numerous, making it a preferred choice in many industries

- Durability Metal grating is exceptionally strong, capable of withstanding heavy loads and harsh environmental conditions without deforming or breaking.

- Safety The open design of metal grating allows for excellent drainage, reducing the risk of slip hazards in wet or greasy environments. It can also be customized with coatings for additional slip resistance.

industrial metal grating

- Cost-Effectiveness While the initial investment might be higher compared to other materials, the longevity and low maintenance costs of metal grating make it a cost-effective choice in the long run

.- Versatility Metal grating can be used in a variety of applications, from walkways and platform surfaces to stair treads and drainage covers. Its adaptability is one of its greatest strengths.

- Environmental Sustainability Many metal grating options are made from recycled materials, making them a more sustainable choice for environmentally conscious industries.

Applications of Industrial Metal Grating

The applications for industrial metal grating are vast and varied. Some common uses include

- Industrial Flooring Metal grating is widely used for flooring in factories, warehouses, and distribution centers due to its load-bearing capabilities and safety features.

- Walkways and Platforms It provides secure walking surfaces for employees and equipment, particularly in areas where water or other liquids may create slippery conditions.

- Stair Treads Metal grating is employed in stairs to ensure safe access between different levels of a facility, reducing slip hazards.

- Trench and Drain Covers Grating is often used to cover trenches or drains, allowing water to flow through while keeping the area secure and safe from accidents.

- Oil and Gas Operations Metal grating is extensively used in oil rigs and gas facilities, where resistance to harsh chemicals and extreme conditions is paramount.

Conclusion

Industrial metal grating is an indispensable component in modern infrastructure, offering a blend of safety, durability, and versatility. As industries continue to evolve, the demand for effective and efficient solutions like metal grating will undoubtedly grow. By understanding the benefits and applications of this vital material, businesses can leverage its strengths to enhance safety and productivity in their operations. Whether in manufacturing, energy, or construction, industrial metal grating stands out as an essential element of industrial design.

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024