- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

2 月 . 08, 2025 05:20

Back to list

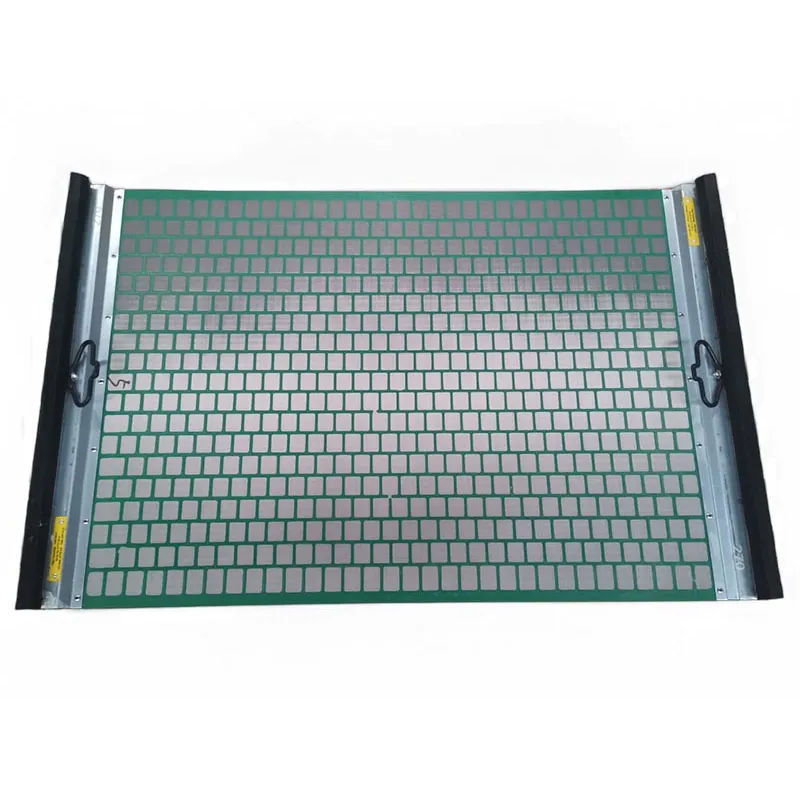

walkway grates

Industrial metal floor grates have stepped beyond their traditional utility, becoming essential components in both industrial design and architecture. Known for their durability and versatility, these grates are engineered to support heavy loads while allowing for efficient drainage, ventilation, and debris filtration. Let's delve deeper into the specifics of industrial metal floor grates, exploring their unique properties, applications, and benefits that make them an indispensable choice for various industrial and commercial settings.

Furthermore, industrial metal floor grates contribute significantly to slip resistance, enhancing workplace safety especially in environments prone to wet and oily conditions. The grates’ textured surfaces provide additional grip underfoot, reducing the likelihood of accidents. This consideration is not only critical from a safety perspective but also impacts operational efficiency by minimizing downtime due to accidents. Customization is another important advantage of industrial metal floor grates. They can be tailored to meet specific industrial requirements, with options for different mesh sizes, thicknesses, and surface treatments such as galvanizing and powder coating. This flexibility ensures that the grates not only fit perfectly into the designated spaces but also match the environmental conditions of the facility. In the broader context of sustainability, industrial metal floor grates can play a pivotal role. Many of these grates are manufactured using recyclable materials, promoting eco-friendly practices within industries. Their long life cycle further reduces the need for frequent replacements, thus minimizing waste and contributing to sustainable industrial operations. In conclusion, industrial metal floor grates offer a combination of strength, safety, efficiency, and sustainability that is unmatched by alternative solutions. For businesses seeking to enhance operational efficiency, improve workplace safety, and adhere to environmental standards, these metal floor grates provide a comprehensive solution. Whether it’s in a large factory, a small workshop, or a commercial kitchen, their practical benefits and adaptability make them a valuable investment in any industrial setting. As industries continue to evolve, the demand for robust, reliable, and eco-friendly components like metal floor grates only continues to grow, underscoring their authoritative status in industrial and commercial applications.

Furthermore, industrial metal floor grates contribute significantly to slip resistance, enhancing workplace safety especially in environments prone to wet and oily conditions. The grates’ textured surfaces provide additional grip underfoot, reducing the likelihood of accidents. This consideration is not only critical from a safety perspective but also impacts operational efficiency by minimizing downtime due to accidents. Customization is another important advantage of industrial metal floor grates. They can be tailored to meet specific industrial requirements, with options for different mesh sizes, thicknesses, and surface treatments such as galvanizing and powder coating. This flexibility ensures that the grates not only fit perfectly into the designated spaces but also match the environmental conditions of the facility. In the broader context of sustainability, industrial metal floor grates can play a pivotal role. Many of these grates are manufactured using recyclable materials, promoting eco-friendly practices within industries. Their long life cycle further reduces the need for frequent replacements, thus minimizing waste and contributing to sustainable industrial operations. In conclusion, industrial metal floor grates offer a combination of strength, safety, efficiency, and sustainability that is unmatched by alternative solutions. For businesses seeking to enhance operational efficiency, improve workplace safety, and adhere to environmental standards, these metal floor grates provide a comprehensive solution. Whether it’s in a large factory, a small workshop, or a commercial kitchen, their practical benefits and adaptability make them a valuable investment in any industrial setting. As industries continue to evolve, the demand for robust, reliable, and eco-friendly components like metal floor grates only continues to grow, underscoring their authoritative status in industrial and commercial applications.

Share

Prev:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024