- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

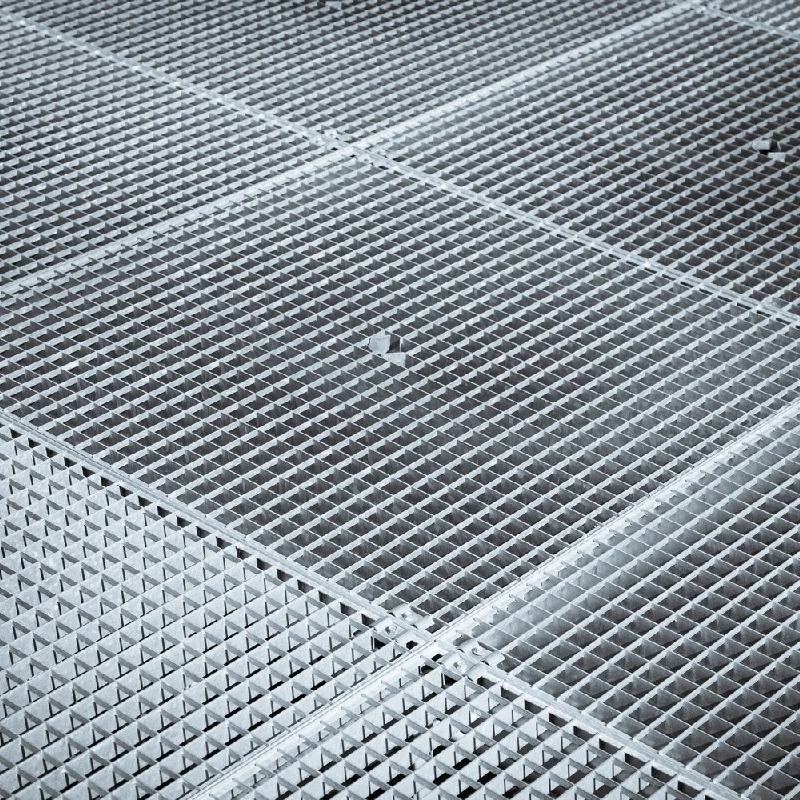

industrial floor grates

Understanding Industrial Floor Grates Importance, Types, and Applications

Industrial floor grates, also known as floor grating or drainage grates, are essential components in various industrial settings. They serve a multitude of functions, primarily focusing on safety, efficiency, and maintenance. In environments where heavy machinery is used or where the ingress of liquids is frequent, proper floor drainage and safe walking surfaces are paramount. This article delves into the importance, types, and applications of industrial floor grates.

Importance of Industrial Floor Grates

One of the primary reasons for utilizing floor grates in industrial settings is to enhance safety. Many industrial sites often deal with spills, leaks, or excess moisture that can create hazardous conditions. Floor grates facilitate efficient drainage by allowing liquids to flow away, which prevents slippery surfaces and reduces the risk of accidents. Moreover, grates help keep work areas clean by filtering out larger debris, thereby promoting a safer and more organized work environment.

In addition to safety, industrial floor grates also contribute to hygiene. In industries such as food processing and pharmaceuticals, maintaining a clean workspace is critical. Floor grates can capture spills and contaminants, which not only aids in the cleanup process but also helps ensure compliance with health regulations.

Types of Industrial Floor Grates

Industrial floor grates come in various materials and designs, tailored to meet the specific needs of different applications. Here are some common types

1. Steel Grates These are the most common type of industrial floor grates, typically made from stainless steel or galvanized steel. Steel grates are durable and strong, making them suitable for heavy loads and high-traffic areas. The corrosion-resistant properties of stainless steel are particularly beneficial in environments where moisture is prevalent.

2. Fiberglass Grates Lightweight and resistant to chemicals, fiberglass grates are often used in environments where exposure to harsh substances is common. They are also non-conductive, making them a safe choice in electrical or sensitive environments.

3. Plastic Grates These are another solution for specific industrial applications. Plastic grates are generally lightweight and corrosion-resistant, making them ideal for environments that require frequent cleaning or for use in water treatment facilities.

industrial floor grates

4. Heavy-Duty Grates Designed for high-load capacity, heavy-duty grates are often used in loading docks and areas where forklift traffic is common. They are engineered to withstand significant weight without warping or breaking.

5. Custom-Made Grates In some instances, industrial needs may call for customized solutions. Manufacturers can create bespoke grates tailored to specific dimensions and load requirements, ensuring optimal performance in unique environments.

Applications of Industrial Floor Grates

Industrial floor grates are versatile and can be found in numerous settings. Their applications include

- Manufacturing Facilities Grates help manage coolant and oil spills, ensuring machinery operates in a safe and efficient environment. - Food Processing Plants They ensure compliance with hygiene standards by enabling easy drainage and cleaning of floors.

- Chemical Processing Plants Non-reactive materials such as fiberglass are crucial in this setting to prevent any chemical reactions and ensure safety.

- Warehouse and Loading Docks Heavy-duty grates can support the weight of forklifts and other equipment while preventing slipping hazards.

- Municipal Wastewater Treatment Grates are essential for controlling water flow and preventing debris from clogging systems.

In conclusion, industrial floor grates play an indispensable role in maintaining safety, hygiene, and operational efficiency across various industrial applications. By choosing the appropriate type of grate for specific environments, businesses can protect their employees, comply with safety regulations, and promote an overall better working atmosphere. As industries evolve and face new challenges, the development of innovative floor grating solutions will continue to enhance operational effectiveness.

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024