- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

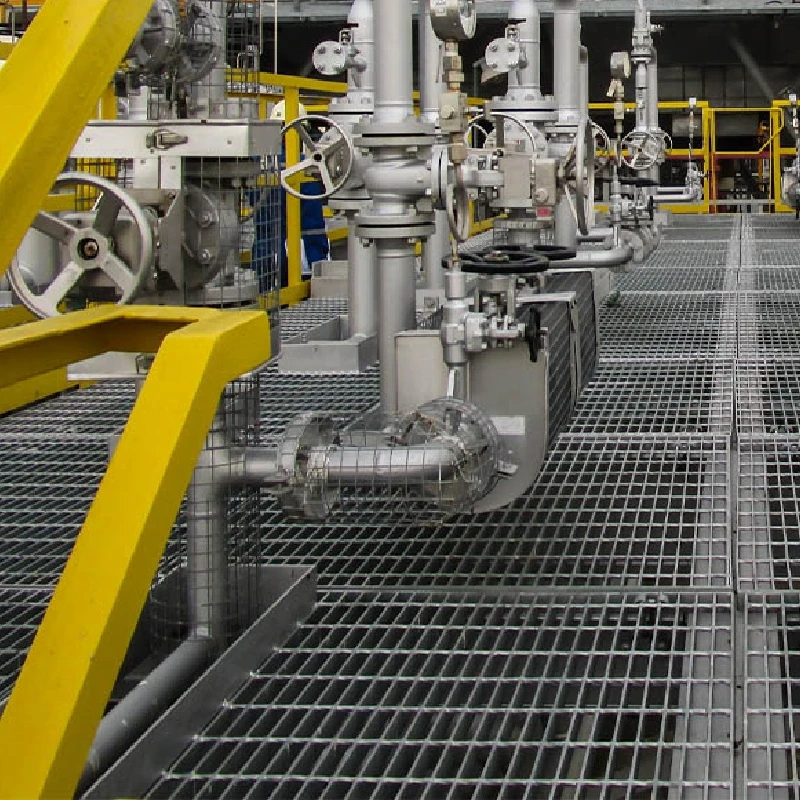

industrial floor grates

Industrial Floor Grates Enhancing Safety and Efficiency in Workspaces

Industrial floor grates play a crucial role in various commercial and industrial settings, providing effective solutions for drainage, ventilation, and maintenance while enhancing safety and efficiency. These grates, often made of durable materials such as galvanized steel, stainless steel, or cast iron, are designed to withstand heavy loads and harsh environmental conditions, making them indispensable in facilities like warehouses, manufacturing plants, and food processing units.

Importance of Industrial Floor Grates

One of the primary purposes of industrial floor grates is to facilitate proper drainage. In environments where liquids are frequently spilled or used, such as food processing and manufacturing areas, effective drainage is essential to prevent hazardous water accumulation. Industrial floor grates allow excess water, chemicals, and debris to flow into a drainage system, reducing the risk of slips and falls that could lead to accidents and injuries. By maintaining a clean and dry workspace, companies can adhere to safety standards while ensuring the well-being of their employees.

In addition to enhancing safety, floor grates also contribute to better air circulation within industrial spaces. Proper ventilation is vital for maintaining a safe and comfortable working environment, particularly in facilities that produce fumes, dust, or heat. Industrial floor grates can be designed to encourage airflow, thereby improving overall air quality. This is especially important in manufacturing environments where machinery generates significant heat, as well as in food processing areas where hygiene standards are critical.

Types of Industrial Floor Grates

Industrial floor grates come in various designs and materials, each catering to specific needs and applications. For instance, heavy-duty grates are engineered to withstand significant weight loads, making them ideal for areas with forklifts and heavy machinery. These grates are typically constructed from robust materials, ensuring long-lasting performance even under extreme conditions.

industrial floor grates

Trench grates, another popular type, are often utilized in conjunction with drainage systems. They are installed along pathways or work areas to collect water and debris effectively. With options for both removable and fitted designs, trench grates enable easy cleaning and maintenance, ensuring that the drainage systems remain unobstructed.

Bar grates, characterized by their open design, offer excellent drainage capabilities while allowing for airflow. These grates are particularly useful in environments where ventilation is a priority. Their design also makes them less prone to clogging, as larger debris can easily pass through, minimizing maintenance efforts.

Installing Industrial Floor Grates

The installation of industrial floor grates is a critical process that can significantly impact safety and efficiency. It is essential to consider the specific requirements of the facility, including expected foot and vehicular traffic, load-bearing capacities, and drainage needs. Proper alignment and placement of grates are necessary to ensure optimal performance, preventing water accumulation or potential blockages.

Moreover, regular inspection and maintenance of floor grates are vital for their longevity and effectiveness. Grates should be periodically checked for damage, rust, or clogging, and any issues should be addressed promptly. A proactive maintenance schedule not only extends the lifespan of the grates but also minimizes disruption in operations, keeping the workspace safe and efficient.

Conclusion

In summary, industrial floor grates are essential components for enhancing safety, ensuring proper drainage, and promoting airflow in various industrial environments. Their durable construction and diverse designs make them suitable for a wide range of applications, helping businesses comply with safety standards and maintain efficient operations. Investing in high-quality floor grates and adhering to proper installation and maintenance practices can significantly contribute to a safer and more productive workplace. As industries continue to evolve, the importance of effective drainage and ventilation solutions will remain a priority, underpinning the vital role of industrial floor grates in modern industrial settings.

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024