- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

1 月 . 15, 2025 09:59

Back to list

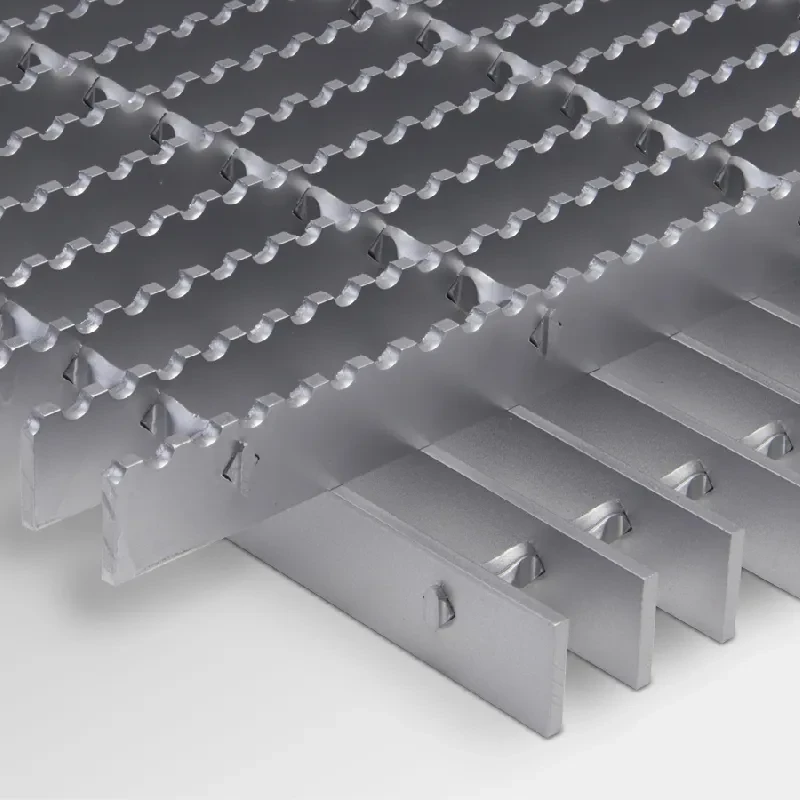

Steel Grating

Hot dip galvanized steel grating is a product widely recognized for its durability, resistance to rust, and cost-effectiveness, making it an ideal choice for various industrial and commercial applications. Over decades of experience in the field, experts have praised this type of steel grating for its ability to sustain in harsh environments, withstanding weather extremes and corrosive substances.

What truly sets hot dip galvanized steel grating apart is the trustworthiness associated with the product's performance and integrity over time. Clients often recount their experiences with legacy installations that have not only endured years of service but also preserved structural safety and aesthetic appeal. Trust in such materials is not easily garnered; it is the outcome of rigorous testing, stringent quality controls, and adherence to international standards that ensure the grating meets all necessary specifications. Consultations with seasoned engineers and construction managers further reinforce the notion that choosing hot dip galvanized steel grating is not purely a product decision but a strategic investment in sustainability and efficiency. Thus, decision-makers in industries reliant on high-quality materials regularly choose this grating solution with confidence. In summary, opting for hot dip galvanized steel grating is synonymous with choosing a product that embodies experience, expertise, authority, and trustworthiness. It is a material rooted in proven scientific processes, underscored by industry benchmarks and acclaimed by practitioners. The enduring satisfaction of partners and stakeholders associated with the grating solutions resonates with the high standards and rigorous expectations that the product fulfills. As demands in construction and manufacturing continue to evolve, the reliance on robust, reliable materials like hot dip galvanized steel grating will undoubtedly persist, supporting structures and infrastructures worldwide safely and efficiently.

What truly sets hot dip galvanized steel grating apart is the trustworthiness associated with the product's performance and integrity over time. Clients often recount their experiences with legacy installations that have not only endured years of service but also preserved structural safety and aesthetic appeal. Trust in such materials is not easily garnered; it is the outcome of rigorous testing, stringent quality controls, and adherence to international standards that ensure the grating meets all necessary specifications. Consultations with seasoned engineers and construction managers further reinforce the notion that choosing hot dip galvanized steel grating is not purely a product decision but a strategic investment in sustainability and efficiency. Thus, decision-makers in industries reliant on high-quality materials regularly choose this grating solution with confidence. In summary, opting for hot dip galvanized steel grating is synonymous with choosing a product that embodies experience, expertise, authority, and trustworthiness. It is a material rooted in proven scientific processes, underscored by industry benchmarks and acclaimed by practitioners. The enduring satisfaction of partners and stakeholders associated with the grating solutions resonates with the high standards and rigorous expectations that the product fulfills. As demands in construction and manufacturing continue to evolve, the reliance on robust, reliable materials like hot dip galvanized steel grating will undoubtedly persist, supporting structures and infrastructures worldwide safely and efficiently.

Share

Prev:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024