- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

1 月 . 24, 2025 01:57

Back to list

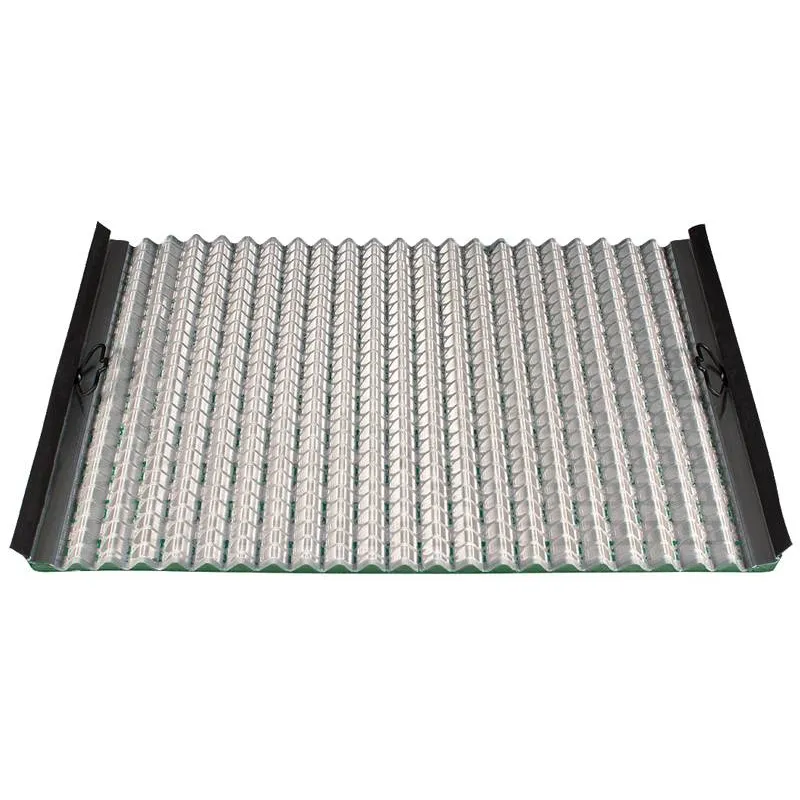

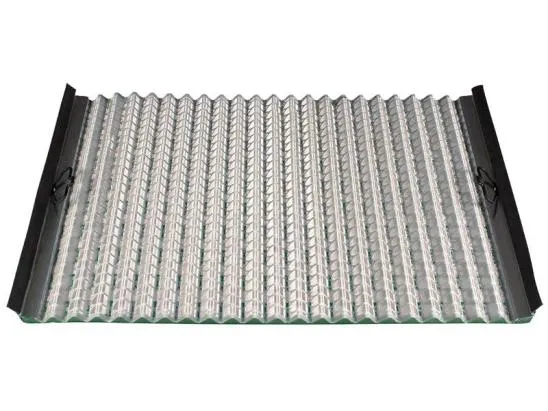

hot dip galvanized grating

In the ever-evolving landscape of industrial materials, hot dip galvanized grating stands as a benchmark of quality and durability, carving its niche with an unbeatable blend of affordability and resilience. As industries worldwide shift towards infrastructure that promises both longevity and cost-effectiveness, understanding the intricacies of hot dip galvanized grating becomes imperative.

The expertise behind the production of these gratings cannot be overstated. Manufacturers adhere to strict quality control measures, ensuring each piece meets industry standards and customer specifications. Through certifications and rigorous testing, these products prove their mettle time and time again. Experts in the field conduct fatigue tests, impact resistance checks, and regular inspections to certify each batch. Authoritativeness in the selection of hot dip galvanized grating also translates into a network of experts who stand by the product’s quality. Structural engineers, architects, and industrial planners frequently recommend galvanized grating due to its documented performance and dependability. By choosing hot dip galvanized solutions, industries tap into decades of collective expertise and industry innovation, which stand as a testament to its value. Trustworthiness, in the context of hot dip galvanized grating, is built upon consistent delivery of quality over time. Companies and governments alike have come to rely on this material, knowing it will not falter under pressure. Whether for pedestrian walkways in urban landscapes or offshore oil rigs, the grating's track record speaks loudly and clearly. This trust is not bought but earned through decades of field applications and validated results. For engineers and project managers, the decision to use hot dip galvanized grating is a strategic one. While the upfront cost might slightly exceed other types of gratings, the overall return on investment through reduced maintenance, extended service life, and high reliability more than compensates for initial expenditures. In conclusion, hot dip galvanized grating emerges as a top-tier choice for sophisticated infrastructure demands. As industries look to build lasting, reliable, and environmentally conscious facilities, this material stands out. It’s not just the zinc coating that strengthens this steel—it’s the decades of innovation and expertise that have gone into refining the process and application. In an era where enduring solutions are not just desired but essential, hot dip galvanized grating provides the expertise, authority, and trustworthiness that industrial sectors require.

The expertise behind the production of these gratings cannot be overstated. Manufacturers adhere to strict quality control measures, ensuring each piece meets industry standards and customer specifications. Through certifications and rigorous testing, these products prove their mettle time and time again. Experts in the field conduct fatigue tests, impact resistance checks, and regular inspections to certify each batch. Authoritativeness in the selection of hot dip galvanized grating also translates into a network of experts who stand by the product’s quality. Structural engineers, architects, and industrial planners frequently recommend galvanized grating due to its documented performance and dependability. By choosing hot dip galvanized solutions, industries tap into decades of collective expertise and industry innovation, which stand as a testament to its value. Trustworthiness, in the context of hot dip galvanized grating, is built upon consistent delivery of quality over time. Companies and governments alike have come to rely on this material, knowing it will not falter under pressure. Whether for pedestrian walkways in urban landscapes or offshore oil rigs, the grating's track record speaks loudly and clearly. This trust is not bought but earned through decades of field applications and validated results. For engineers and project managers, the decision to use hot dip galvanized grating is a strategic one. While the upfront cost might slightly exceed other types of gratings, the overall return on investment through reduced maintenance, extended service life, and high reliability more than compensates for initial expenditures. In conclusion, hot dip galvanized grating emerges as a top-tier choice for sophisticated infrastructure demands. As industries look to build lasting, reliable, and environmentally conscious facilities, this material stands out. It’s not just the zinc coating that strengthens this steel—it’s the decades of innovation and expertise that have gone into refining the process and application. In an era where enduring solutions are not just desired but essential, hot dip galvanized grating provides the expertise, authority, and trustworthiness that industrial sectors require.

Share

Prev:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024