- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

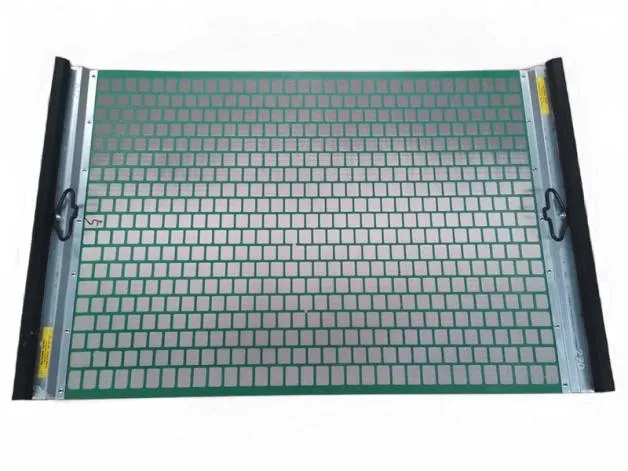

Hot Dip Galvanized Steel Grating - Durable and Corrosion-Resistant Solutions

Hot Dip Galvanized Steel Grating An Overview

Hot dip galvanized steel grating has garnered significant attention across various industries due to its exceptional durability and anti-corrosive properties. This versatile material is widely used in applications ranging from industrial flooring to walkways and drainage covers. Understanding the manufacturing process, benefits, and applications of hot dip galvanized steel grating can provide valuable insights for engineers, construction professionals, and facility managers.

Manufacturing Process

The production of hot dip galvanized steel grating involves several stages. Initially, raw steel bars are shaped into a grid pattern, forming the grating itself. This grid design allows for efficient drainage and visibility, making it ideal for numerous applications. The next crucial step is the hot dip galvanizing process, where the steel grating is submerged in a molten zinc bath at high temperatures. This process creates a robust protective layer of zinc, which adheres to the steel surface through a metallurgical reaction, providing long-lasting protection against corrosion and wear.

Benefits

1. Durability Hot dip galvanized steel grating exhibits remarkable strength and resistance to harsh environmental conditions. The zinc coating acts as a barrier against moisture, chemicals, and atmospheric pollutants, significantly extending the lifespan of the material.

2. Low Maintenance One of the standout features of hot dip galvanized steel grating is its minimal maintenance requirements. Unlike uncoated steel, which may require frequent painting or replacement, galvanized grating can withstand years of exposure with little to no upkeep.

hot dip galvanized steel grating

3. Safety The open design of steel grating allows for effective drainage, reducing the risk of water accumulation and slippery surfaces. This enhances safety in industrial environments where spills may occur.

4. Environmental Friendliness The galvanization process not only prolongs the life of the grating but also reduces waste. Steel grating can be recycled at the end of its lifespan, making it an environmentally friendly choice.

Applications

Hot dip galvanized steel grating is employed in a diverse range of sectors. In industrial environments, it is commonly used for flooring and platform applications, providing safe and sturdy surfaces for workers. In municipal projects, it serves as drainage grates, allowing for efficient water flow while maintaining structural integrity. Additionally, it finds usefulness in transportation infrastructure, such as in bridges and roadways, where durability and safety are paramount.

Conclusion

In summary, hot dip galvanized steel grating is a critical component in many industrial, commercial, and municipal applications. Its impressive durability, low maintenance, and safety features make it an excellent choice for a variety of environments. As industries continue to seek reliable materials that withstand the test of time, hot dip galvanized steel grating will undoubtedly remain a cornerstone of modern construction and design. By leveraging the advantages of this material, engineers and construction professionals can contribute to safer and more sustainable infrastructure solutions.

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024