- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

2 月 . 10, 2025 11:46

Back to list

helideck perimeter net

In the high-stakes environment of offshore operations, where safety is paramount, the helideck safety net plays a crucial role in safeguarding lives and equipment. Helideck safety nets, though seemingly simple, embody a complex integration of design, material science, and operational expertise. This piece aims to delve into the intricacies of helideck safety nets, providing not just an overview of their importance, but also a comprehensive guide grounded in real-world experience and expert insights.

Expertise in helideck safety net systems is not only about understanding the technicalities but also about appreciating the environments in which they operate. Offshore conditions are unforgiving, with fluctuating weather patterns and corrosive atmospheres. Experts in the field are those who continuously update their knowledge about materials science advancements, ensuring that the nets used are of the highest quality and durability. Innovations such as net coatings that resist marine growth and advanced anchoring systems exemplify the ongoing evolution in helideck safety technologies. Authority in the industry often comes from manufacturers and providers of helideck safety systems who invest in research and development. Engaging with these leaders can offer insights into the latest trends and technologies in safety net design and application. Companies that proactively publish white papers and case studies contribute significantly to the collective knowledge base, allowing operators worldwide to benefit from shared expertise. Trustworthiness is built through a track record of successful installations and accident prevention cases. Customer testimonials and certifications from recognized bodies further validate a safety net provider's products. When selecting a helideck safety net, potential buyers are encouraged to consider companies that can demonstrate a history of reliability and excellence in service. In conclusion, the helideck safety net is an indispensable element of offshore safety. With needs ranging from the materials selected to the precision in installation and maintenance, each aspect is underpinned by extensive expertise and authority. Companies dedicated to advancing these systems significantly enhance the trust operators place in them. For stakeholders in the offshore industry, investing in top-tier helideck safety nets translates to saving lives, protecting assets, and maintaining seamless operations.

Expertise in helideck safety net systems is not only about understanding the technicalities but also about appreciating the environments in which they operate. Offshore conditions are unforgiving, with fluctuating weather patterns and corrosive atmospheres. Experts in the field are those who continuously update their knowledge about materials science advancements, ensuring that the nets used are of the highest quality and durability. Innovations such as net coatings that resist marine growth and advanced anchoring systems exemplify the ongoing evolution in helideck safety technologies. Authority in the industry often comes from manufacturers and providers of helideck safety systems who invest in research and development. Engaging with these leaders can offer insights into the latest trends and technologies in safety net design and application. Companies that proactively publish white papers and case studies contribute significantly to the collective knowledge base, allowing operators worldwide to benefit from shared expertise. Trustworthiness is built through a track record of successful installations and accident prevention cases. Customer testimonials and certifications from recognized bodies further validate a safety net provider's products. When selecting a helideck safety net, potential buyers are encouraged to consider companies that can demonstrate a history of reliability and excellence in service. In conclusion, the helideck safety net is an indispensable element of offshore safety. With needs ranging from the materials selected to the precision in installation and maintenance, each aspect is underpinned by extensive expertise and authority. Companies dedicated to advancing these systems significantly enhance the trust operators place in them. For stakeholders in the offshore industry, investing in top-tier helideck safety nets translates to saving lives, protecting assets, and maintaining seamless operations.

Share

Prev:

Next:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

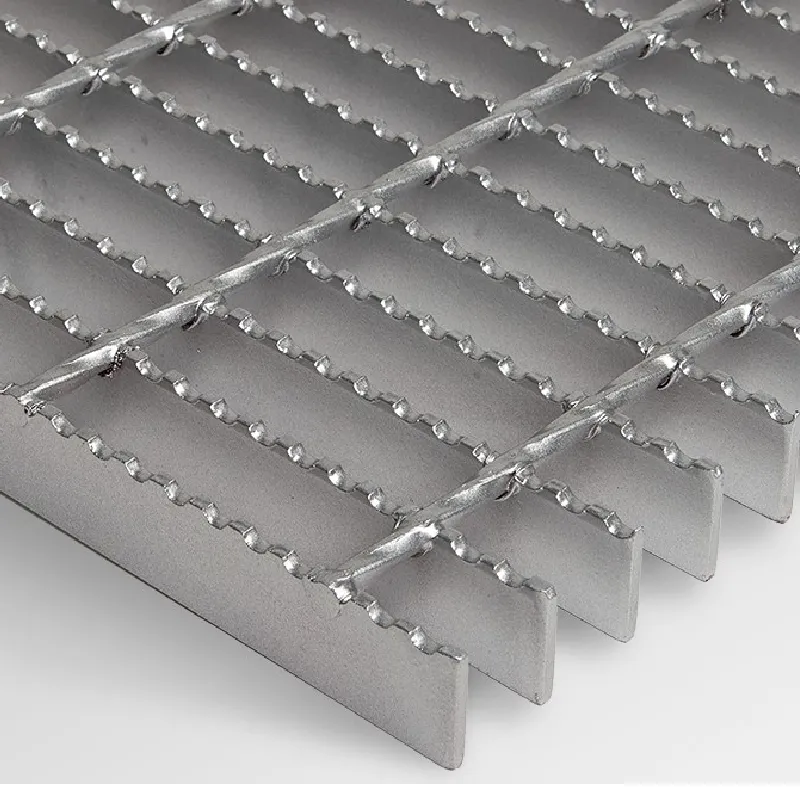

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024