- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

2 月 . 11, 2025 03:10

Back to list

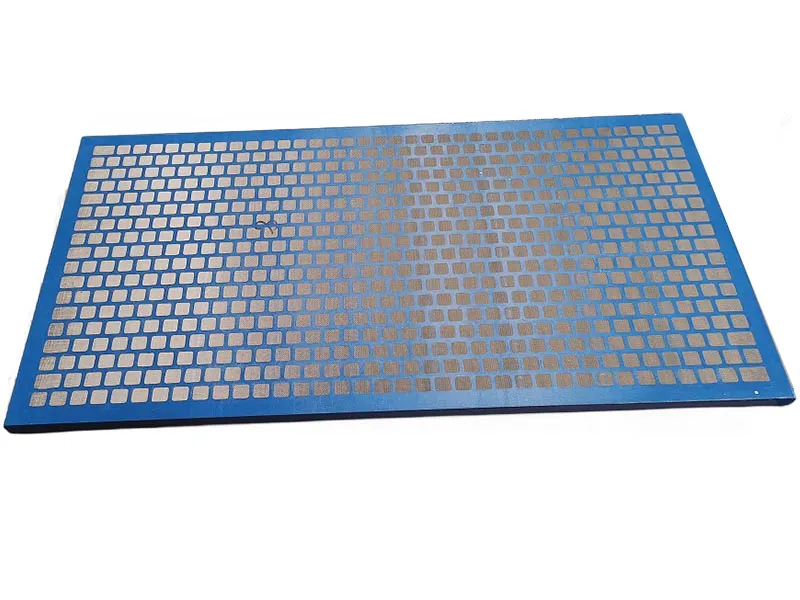

heavy duty mild steel grating

Heavy steel grating stands as a paramount choice for industrial and commercial project undertakings, providing unparalleled durability, safety, and versatility. To leverage the optimal benefits of this robust material, it's crucial to delve into the nuances of its application, quality, and procurement process. This article aims to unfold insights derived from hands-on experience, backed by industry expertise, to ensure informed decision-making.

When purchasing heavy steel grating, establishing trust with suppliers and verifying their credentials is essential. Reputable suppliers not only provide materials of verified quality but also offer expert guidance on grating selection and maintenance. Industry authorities often endorse suppliers with certifications and positive customer testimonials, which act as gatekeepers for establishing reliability. To bolster trustworthiness, users are encouraged to document their experiences with heavy steel grating. Sharing testimonials on platforms like Google Reviews, industry forums, or at conferences enhances community knowledge and empowers peers in making informed choices. Such community-driven insights bridge the gap between technical specifications and real-world application, fostering an environment of trust among consumer bases. Drawing from real-world usage and comprehensive industry knowledge, heavy steel grating emerges as a resource of unmatched potential—a linchpin in constructing spaces that are not merely functional but resilient and safe. Investing time in understanding its properties, judicious selection, and proficient installation inevitably translates into long-term gains—reducing maintenance costs, enhancing safety, and ensuring compliance with evolving industry standards. In conclusion, leveraging heavy steel grating requires a multifaceted approach—one rooted in expertise, credible sourcing, and ongoing engagement with the broader industrial community. Through these concerted efforts, heavy steel grating not only becomes an essential building material but a cornerstone of successful project execution in demanding environments.

When purchasing heavy steel grating, establishing trust with suppliers and verifying their credentials is essential. Reputable suppliers not only provide materials of verified quality but also offer expert guidance on grating selection and maintenance. Industry authorities often endorse suppliers with certifications and positive customer testimonials, which act as gatekeepers for establishing reliability. To bolster trustworthiness, users are encouraged to document their experiences with heavy steel grating. Sharing testimonials on platforms like Google Reviews, industry forums, or at conferences enhances community knowledge and empowers peers in making informed choices. Such community-driven insights bridge the gap between technical specifications and real-world application, fostering an environment of trust among consumer bases. Drawing from real-world usage and comprehensive industry knowledge, heavy steel grating emerges as a resource of unmatched potential—a linchpin in constructing spaces that are not merely functional but resilient and safe. Investing time in understanding its properties, judicious selection, and proficient installation inevitably translates into long-term gains—reducing maintenance costs, enhancing safety, and ensuring compliance with evolving industry standards. In conclusion, leveraging heavy steel grating requires a multifaceted approach—one rooted in expertise, credible sourcing, and ongoing engagement with the broader industrial community. Through these concerted efforts, heavy steel grating not only becomes an essential building material but a cornerstone of successful project execution in demanding environments.

Share

Prev:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024